Choosing a pellet mill for a wood pellet business can be tricky. Especially if it is your first time. Don’t worry.

The following tips will help you get a perfect pellet machine.

Consider the Size of your Business

Different types of pellet makers are available in the market. Each comes with distinct features and pellet-producing capacity.

If you want to manufacture wood pellets on a small scale, choose a small-sized machine. For bulk production, you will need an industrial pellet-making mill.

People prefer a flat die machine for making pellets in small quantities. These machines are compact, energy-efficient, and make low noise. You do not need any specialized workspace for them.

On the other hand, if you want to produce pellets on a large scale, invest in a ring-die pellet machine. A vertical-ring-die machine can make up to 1000 kg pellets per hour.

Die Type

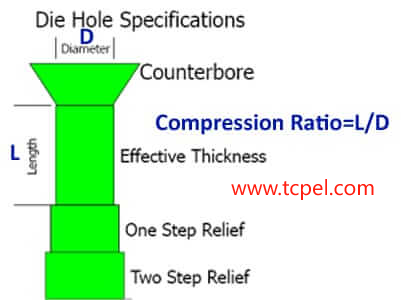

The quality of pellets depends on the excellence of the die to some extent. Analyze all the pellet mill die specifications carefully.

Make sure the machine uses premium quality stainless steel die.

Also, check for the compression ratio of the pellet die. It refers to the ratio of the effective working length of the die to the die thickness.

The die with a higher compression ratio makes denser pellets, while low ratio dies produce lighter pellets.

Choose a pellet die that provides adequate compression to produce excellent pellets.

Manufacturers make pellet dies with different ratios. You can choose them based on the nature of your raw material.

For wood shaving, you can choose a die ratio of 1:5, whereas for corn straw, it could be 1:8.

The die with low compression ratio wears off slowly. However, it affects the pellets’ quality.

Consider Your Budget

The complete wood pellet manufacturing process requires a lot of equipment. Along with a pellet mill, you will need a dryer, hammer mill, and cooling machine.

If you are starting a business at a small level, you can buy only a pellet mill. Still, you need a budget for raw materials, electricity, and other expenses.

Explore pellet machines of different brands and choose the supplier offering the desired pellet mill at the best price.

Power Source of Machine

Pellet machines run on different energy sources. Depending on the available energy source, you can buy a pellet mill that runs on electricity, diesel, or other power source.

Type Raw materials

Different pellet machines process distinct raw materials.

Some pellet mills can make biomass pellets from wood waste, while others use only certain materials.

There are pellet mills that are more suitable for making animal feed pellets. So make a choice based on your requirements.

Safety Features

Advanced pellet mills feature a wide range of safety features to safeguard operators.

Make sure the mill you choose has all the necessary safety features.

It must have an emergency stop button, overload protection, and automatic shutdown feature on malfunction.

Maintenance Requirement

Before you finalize a pellet mill, learn how easy it is to clean it. Also, learn about lubricating and other maintenance requirements.

Choose Reputable Manufacturer

Regardless of the type of machine you need, buy it from a renowned, experienced, and trustworthy manufacturer.

Look for reviews and references about the machine and manufacturer.

In addition to this, get to know about customer support and warranty services. Most reliable manufacturers offer a warranty on manufacturing defects.

Some pellet machine making companies also provide demos or trial runs. Get hands-on experience before you actually buy the machine.