If you are looking for an easy and affordable way to get rid of excess wood, a wood shaving machine may be the perfect option for you. Wood shaving machines are designed to quickly and easily turn wood into small pieces that can be easily disposed of. This can be a great option for people who have a lot of extra wood on their property, or who need to get rid of large amounts of wood quickly. In this article, we will discuss what wood shaving machines are, how they work, and some of the benefits that they offer.

What Is A Wood Shaving Machine And How Does It Work?

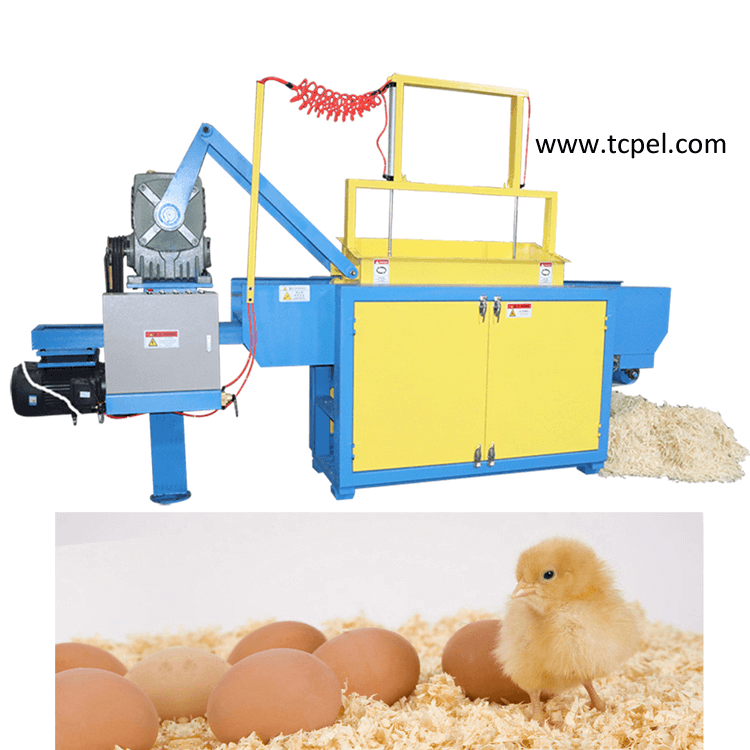

A wood shaving machine is an industrial tool designed to convert raw wood into small, uniform wood shavings. This type of machine typically consists of a series of rotating cutting blades powered by high-speed motors. The speed and force of the blades extract wood fibers from the raw wood material, producing long, thin shavings that are ideal for use in a variety of applications.

In order to work properly, a wood shaving machine relies on several key components. The motor is a critical part of the system since it determines both the velocity and torque required to cut through the hardwood materials. In addition, the conveyor system allows fresh pieces of lumber to be processed quickly and efficiently while ensuring that the shavings are smoothly extracted at regular intervals.

Finally, sensors within the machine help to ensure optimal blade alignment and guard against damage or injury. Overall, a wood shaving machine is a highly effective tool for creating tailored shavings for industrial or domestic uses.

What Are The Benefits Of Using A Wood-Shaving Machine?

There are many benefits to using a wood-shaving machine in your workshop.

First and foremost, this type of machine enables you to create uniform shavings from a variety of wood types, including softwoods like pine and hardwoods like oak.

In addition, by using a wood-shaving machine, you can produce shavings that are much thinner than those you would get with traditional blades or rasps. Because these fine shavings are denser than the coarse ones produced by other tools, they also burn much more efficiently in a fireplace or stove.

Finally, using a wood shaving machine is an excellent way to reduce waste in the workshop, as it will help you to turn leftover scraps into useful materials. So whether you’re looking to improve your workflow or save money on fuel costs, a wood-shaving machine has everything you need. Read more on how to make wood shavings.

Types Of Wood-Shaving Machines

There are several different types of wood-shaving machines that can be used to create shavings from logs and branches.

The simplest type of machine is the hand-cranked model, which consists of a blade that rotates rapidly against a solid surface. This type of machine is typically used for small batches of material and requires some manual labor in order to operate.

A more advanced option is the band saw shaving machine, which uses a long, rotating blade to cut the material into long slivers. This type of machine offers faster results while still producing top-quality shavings suitable for a variety of purposes.

Finally, there is the disk saw machine, which uses a rotating disk to cut through wood at high speed. This type of machine produces smooth, finely-ground wood shavings that can be used as fuel or bedding.

Ultimately, choosing these different types of wood shaving machines will depend on factors such as budget and intended use.

Tips For Choosing The Right Wood-Shaving Machine For Your Needs

When it comes to wood-shaving devices, there are many factors to consider. Which type of machine is best for your needs? What size and power requirements should you look for? And how do you ensure that the machine you choose will be able to deliver top-quality shavings every time? Before making a decision about which wood-shaving machine is right for you, here are some tips to keep in mind:

1. Consider the types of materials that you will be shaving. Not all machines are suitable for all types of materials, so it’s important to choose one that can accommodate your specific needs. For example, if you plan on processing both soft and hardwoods, you may want to look for a machine with variable speed settings or other adjustable controls.

2. Determine the ideal output levels for your operation. All wood shaving machines have different strengths and capabilities, so it’s important to find a model that can meet your precise production requirements without breaking down too quickly. Do some research into each model’s various operating specifications, such as motor power and blade speed, in order to choose wisely.

3. Invest in quality components whenever possible. While price is always an important consideration when shopping for any kind of machinery, it isn’t always wise to go with the lowest-cost option available just because it seems like a great bargain at first glance. Make sure that any model you’re considering is made from durable materials that can withstand regular use over many years while still delivering optimal results each time you turn on the machine.

After all, your goal should be long-term productivity rather than short-term savings! For your best choice, visit https://www.tcpel.com/wood-shaving-machine