Wind turbine blade design and testing project

Brian Greco

Nathaniel Michener

Mike McNally

Patrick Husted

Daniel Kim

Blade Geometries:

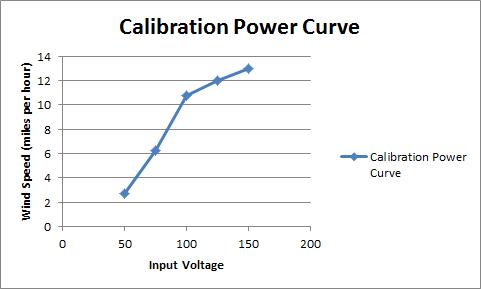

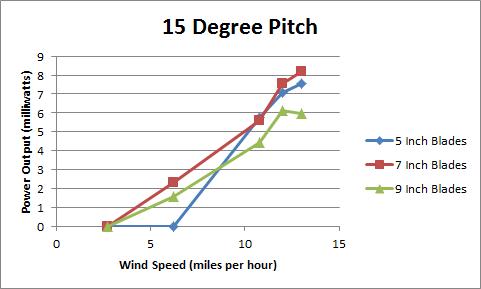

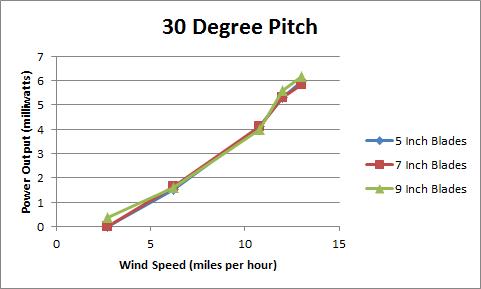

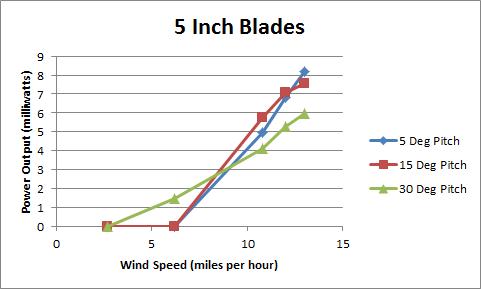

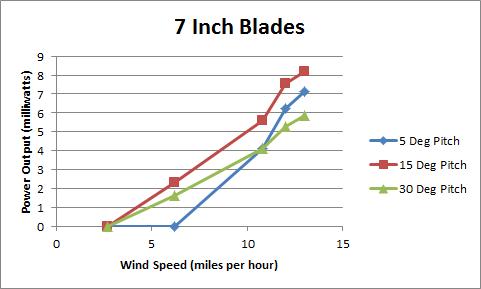

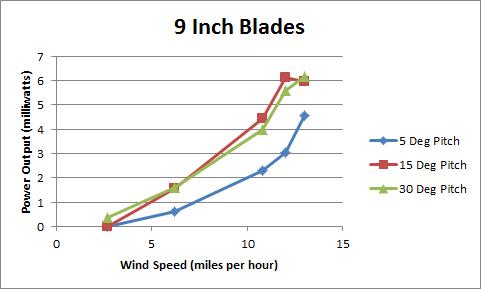

The experiment used 3 rectangular blades with a constant width of 1.5 inches. From hub to tip, blades had span lengths of 5 inches, 7 inches, and 9 inches; the actual blade surface area was less because .75 inches were dedicated to the dowel attaching the blade to the hub. Change in pitch was also explored. With each span length, different pitches were tested for power output. The pitches tested: 5 degrees, 15 degrees and 30 degrees. Thus, a total of 9 unique blade arrangements were tested at 5 different wind speeds. Following are power curves comparing first the impacts of blade length at a given pitch, and next the impacts of blade pitch with a given length.

In the case of 5 degree pitch, 5 inch blades seemed to function best, with significantly better performance than the 9 inch blades.

A 15 degree pitch angle changed things; all three blade lengths were now closer in their performance and better than at a 5 degree pitch.

The 30 degree pitch caused a significant drop in performance across all three blade lengths; blade length seemed to have almost no effect whatsoever at this pitch angle. Cut-in speed was better, however—the blades started moving in about 7 mph winds, which was only possible for the longer blades at lower pitches.

The 5 inch blades are interesting; the curves show a less-than-distinct trend. At different wind speeds, different pitch configurations seemed more efficient.

The 7 inch blade curves are far clearer; the 15 degree pitch is the most effective, as expected.

The 9 inch blades show the same trend, with the 15 degree pitch power curve being best, but the blades pitched at 30 degrees are a close second.

Bulleted Lessons Learned:

● Higher wind speeds at 9 inch span length caused potentially dangerous vibrations

● The most optimal blade length and pitch was 7 in and 15 degrees

● Longer blade lengths do not necessarily improve voltage or current generated; in fact, the 9 inch blades had the lowest power outputs

● High pitches do not increase power output, but make cut-in speed lower; therefore, a turbine in a low-wind environment could function better with a pitch higher than 15 degrees, even though that is supposed to be the optimal angle

● Variation in blade length at higher pitches shows no change in power output at this scale, and showed less-than-distinct trends at lower pitches as well; it was obvious that the 9-inch blades were worst

● Longer, heavier blades still manage to have lower cut-in speeds, especially combined with high pitch angles

3 Comments

unicomposite posted on April 10, 2023 at 9:55 am

Wind blade is the most basic and important part of the blade type in wind turbine generator. The good design, reliable quality and excellent performance is the decisive factor to ensure the normal and stable operation of the generator unit. General materials used in the production of wind blades are wood, metal, engineering plastics, and fiberglass material, etc.

Highway Guardrail posted on April 10, 2023 at 10:08 am

good research

Thermoplastic posted on May 4, 2023 at 9:40 pm

Thermoplastic road marking machine (pavement marking machine) is special-purpose equipment for road marking.