Hydraulic pumps are used in a variety of industries to move fluid, and understanding how they function is essential to ensuring they’re used effectively. In this article, we will discuss the basics of hydraulic pumps and how you can use efficiency ratings to judge their performance.

Efficiency is important when it comes to hydraulic pumps. Inefficient pumps will cause more wear and tear on your machine, eventually leading to its premature failure. So how can you tell if a pump is efficient? The answer lies in its design and how well it functions.

How does a hydraulic pump work?

A hydraulic pump is a machine that uses hydraulic pressure to move fluid or material. Hydraulic pumps are used in a variety of applications, including automotive and industrial manufacturing, construction, and agriculture.

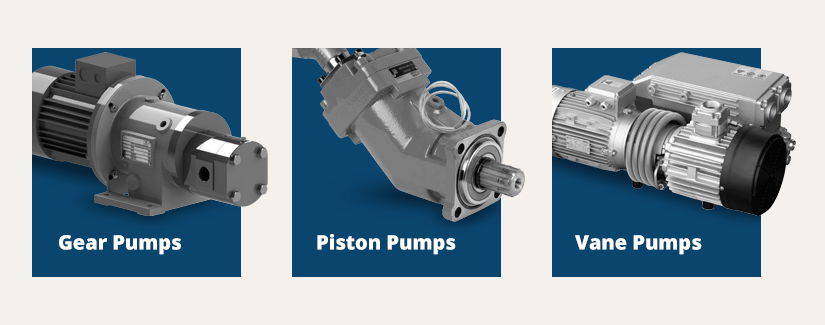

There are two main types of hydraulic pumps: pistons and rotary vane pumps. Each type has its own advantages and disadvantages.

Piston pumps are the most common type of hydraulic pump. They use pistons to move the fluid. The pistons are connected to a cylinder, which houses the moving parts (the impeller and the turbine). When you press down on the piston, it moves the cylinder and the impeller. This causes the turbine to spin, which creates pressure against the fluid flow. The pressure pushes the fluid through the pump.

Rotary vane pumps are less common than piston pumps, but they have some advantages. For example, they can be more efficient than piston pumps. This is because they use a rotor instead of a piston to move the fluid. The rotor spins around an axis, which causes the fluid to flow through it. This makes it easier for the pump to create pressure against the fluid flow.

What are the different types of hydraulic pumps?

Hydraulic pumps are both efficient and reliable. They come in a variety of types, including centrifugal, screw, and piston pumps. Here’s a quick rundown of the different types:

Centrifugal pumps use a spinning disk to move the fluid. Because they rely on a rotating component, centrifugal pumps are relatively inefficient.

Screw pumps use a helical screw to move the fluid. They’re more efficient than centrifugal pumps because they use less energy to move the same amount of fluid.

Piston pumps use pistons to push and pull the fluid. They’re the most efficient type of pump because they use the least amount of energy to move the same amount of fluid.

How to measure the efficiency of a hydraulic pump

When it comes to picking a hydraulic pump for your project, it is important to consider its efficiency. Hydraulic pumps can be efficient in different ways, but there are a few things you can do to measure how effective the pump is.

The first thing you want to do is measure the horsepower required to operate the pump. If the horsepower requirement is high, then the pump may not be very efficient. However, if the horsepower requirement is low, then the pump may be more efficient. You can also check to see how much water the pump can move per minute. If the water flow is low, then the pump may not be very efficient. Lastly, you can measure the energy used to power the pump. If this number is high, then the pump may not be very efficient. Overall, these are just a few tips that you can use to determine an individual pump’s efficiency.

What can happen to a hydraulic pump if it isn’t efficient?

A hydraulic pump is a device that uses pressurized fluid to move objects. It is a common component in many machines, including cars and planes. If a hydraulic pump isn’t efficient, it can cause problems. Inefficient pumps can overheat, which can damage the machine they’re working on. They can also cause the fluid to escape, which can lead to structural failures. If you’re using an inefficient pump, it’s important to fix it as soon as possible.

A hydraulic pump is a device that uses hydraulic fluid to move objects or pressurize fluids. They are used in a variety of applications, including mining, construction, and agriculture. A hydraulic pump can be efficient or not, and if it isn’t, it can cause some problems.

If a hydraulic pump isn’t efficient, it can result in decreased efficiency and a longer lifespan for the pump. Additionally, if the pump contains debris or foreign objects, it can clog the pump and cause damage. Finally, if the pump is not working efficiently due to an inefficient motor, it can create heat that can damage other parts of the machine.

If you notice any of these problems with your hydraulic pump, it may be time to replace it.

What can be done to improve the efficiency of a hydraulic pump?

There are a few things that can be done to improve the efficiency of a hydraulic pump. One of the most common ways to achieve increased efficiency is by using a higher pressure rating for the pump. This means that the pump can handle higher pressures without breaking down. Additionally, it is important to keep the pump clean and free of debris. This will help to reduce the amount of energy that is required to move the fluid through the pump. Finally, it is important to replace worn or damaged parts as soon as possible in order to maintain maximum efficiency.

There are many things that can be done to improve the efficiency of a hydraulic pump. One way to reduce energy consumption is to use a more efficient motor. Another way to reduce energy consumption is to design the pump so that it operates at a lower speed. Additionally, it is important to properly maintain the pump so that it operates at its peak efficiency.

How can you tell if a hydraulic pump is efficient. please click topkitparts see more