Hydraulic pumps are important pieces of machinery used in a variety of industries. In this article, we will look at the two types of hydraulic pumps and what they are used for.

Piston pumps are the most common types of hydraulic pumps, and they use a piston to move fluid around. This type of pump is used in a variety of applications, including agriculture, automotive manufacturing, and oil and gas production.

Vane pumps are a newer type of hydraulic pump, and they use a series of vanes to move fluid around. This type of pump is used in applications that require high accuracy and precision, such as medical devices and aerospace engineering.

What is a hydraulic pump?

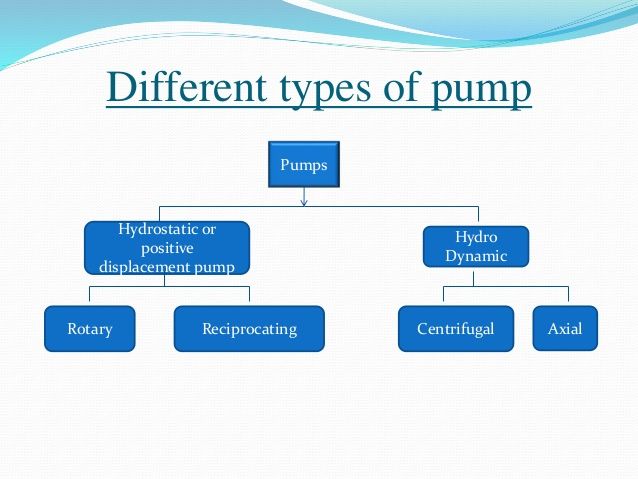

A hydraulic pump is a machine that uses pressurized fluid to move objects or fluids. They come in two main types: rotary and axial. Rotary pumps are typically smaller and more efficient, while axial pumps are larger and more powerful.

A hydraulic pump is powered by a motor, which turns the shaft that the pump is mounted on. The pressurized fluid travels through a series of tubes and chambers, which extracts energy from the engine to move the object or fluid.

How a Hydraulic Pump Works?

A hydraulic pump is a mechanical device used to move fluids using the pressure of a fluid filled cylinder. The most common type are rotary piston pumps, which use the principles of double acting and single acting pumps.

In a double acting pump, the pressure in the cylinder is divided into two equal parts. The first part is used to operate the pump and move the fluid. The second part is used to maintain the pressure in the cylinder, and it is also connected to a Relief Valve to allow fluid to escape if the pump becomes overloaded.

In a single acting pump, the pressure in the cylinder is always high, and the only way to increase or decrease the flow of fluid is by opening and closing a valve.

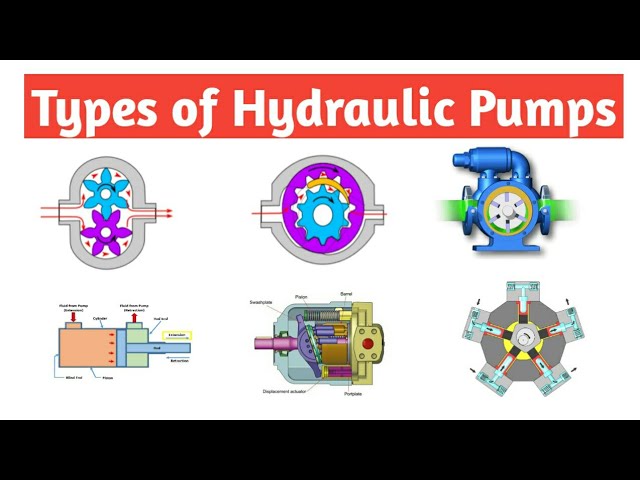

Types of Hydraulic Pumps

There are two types of hydraulic pumps: impulse and rotary. Impulse pumps work by using an initial burst of energy to create a pressure difference that generates motion. Rotary pumps use a spinning rotor to create pressure differences that generate motion.

The main difference between impulse and rotary pumps is the way they generate motion. In impulse pumps, the initial burst of energy creates a pressure difference that moves the piston. Rotary pumps use a spinning rotor to create pressure differences that move the object being pumped. This means that they are better suited for applications where you need to move fluids quickly, like in factories or oil rigs.

What are the differences between the two types of pumps?

The two types of hydraulic pumps are the piston pump and the rotary pump. The piston pump is simpler than the rotary pump and is used more often in smaller applications. The rotary pump is more powerful and is used more often in bigger applications.

The piston pump is powered by the pressure of the fluid inside the pump, while the rotary pump is powered by a motor. The piston pump has a reciprocating motion while the rotary pump has a rotating motion.

The piston pump is less expensive than the rotary pump, but the rotary pump is more powerful.

The piston pump is able to move larger volumes of fluid than the rotary pump.

The piston pump is able to move fluid at a slower speed than the rotary pump.

The rotary pump is more efficient than the piston pump because it uses less energy.

The rotary pump is also less likely to jam than the piston pump.

What are the Pros and Cons of different kinds?

There are two main types of hydraulic pumps- Pneumatic and Electric.

Pneumatic pumps are the oldest type of hydraulic pump, and they use air to create a force. This type of pump is generally less expensive than electric pumps, but they can also be less powerful.

Electric pumps are the most common type of hydraulic pump, and they use electricity to create a force. This type of pump is usually more powerful than pneumatic pumps, and they are also often faster. However, electric pumps can be more expensive than pneumatic pumps.

Different Applications For Different Hydraulic Pumps

Different hydraulic pumps are used for different applications.

There are two types of hydraulic pumps:

1. Piston pump: This is the most common type of hydraulic pump, and it uses a piston to move the fluid.

2. Rotary pump: Rotary pumps use a rotor to move the fluid. They are faster than piston pumps, and they are used for applications where high speed is important, such as in chemical processing plants or water treatment facilities.

How do you know which type you need?

hydraulic pumps can be classified into two types: diaphragm pumps and piston pumps. Diaphragm pumps use a flexible diaphragm to move liquid or gas through a vented chamber. Piston pumps use pistons to push and pull fluid through a sealed chamber. Each type has its own advantages and disadvantages.

If you are looking for a small, low-power pump that is easy to use, you may want to consider a piston pump. If you need a pump with more power, or if you need a pump that can handle larger volumes of fluid, you may want to choose a diaphragm pump.

You can also use the type of pump that is best suited for the task at hand to determine which one will be the best option. For example, if you need a pump to move liquid oil, a piston pump would be the best option. If you are looking to move water, a diaphragm pump would be the better option.

Conclusion

In this article, we will be taking a look at the two types of hydraulic pumps: the rotary and the centrifugal. We will also discuss their advantages and disadvantages. Hopefully, this information will help you make a more informed decision when it comes to choosing the right pump for your specific application.

What are the two types of hydraulic pumps. please click topkitparts see more