Hydraulic pumps are devices that use pressurized fluid to move objects or materials. They come in both directional and non-directional varieties, and it can be difficult to determine which type is best for a particular application. This article will explore the different types of hydraulic pumps and their advantages and disadvantages.

directional pumps are best for applications that require consistent flow in one direction, such as in a plumbing system. They typically use a single impeller to move fluid in one direction and are less likely to become blocked.

are best for applications that require consistent flow in one direction, such as in a plumbing system. They typically use a single impeller to move fluid in one direction and are less likely to become blocked. non-directional pumps can be used for either purposes, but are typically cheaper and more efficient than directional pumps. They don’t require a separate impeller, so they can be smaller and more compact. However, they may not be as effective at moving fluid in one specific direction.

What is a hydraulic pump?

A hydraulic pump is a machine that uses the power of pressurized fluid to move objects. A hydraulic pump is a directional engine, meaning that it can be turned in one or more directions to move an object. This makes it an effective choice for moving heavy objects where space is limited.

A hydraulic pump works by using a high-pressure fluid to push or pull objects. The hydraulic fluid is delivered to the pump through a pipeline, where it is pressurized to a high level. This pressure allows the pump to move objects with great force.

Hydraulic pumps come in a variety of sizes and shapes, and they can be used in a variety of applications. They are often used to move heavy objects, such as materials for construction or mining.

How do hydraulic pumps work?

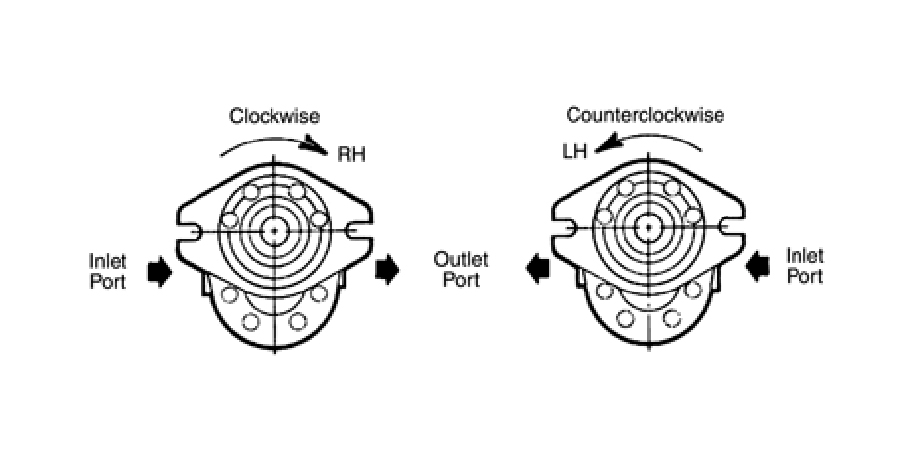

Hydraulic pumps are directional because they use a rotating rotor to create a flow of fluid. The direction of the flow is controlled by the orientation of the rotor. This allows hydraulic pumps to be used in either forward or reverse directions.

In forward operation, the fluid flow is directed towards the front of the pump. In reverse operation, the fluid flow is directed away from the front of the pump.

Why are pumps directional?

Pumps are directional because they move fluid in one direction. This is why they are often used in hydraulic systems, which are used in industrial settings to move fluids.

Some pumps are also directional because of their impellers. These pumps use an impeller to move the fluid in one direction.

Some pumps are directional because of their flow rate. These pumps can move a lot of fluid in a short amount of time, which is why they are often used in faster-moving applications.

Does the direction of a hydraulic pump matter?

Yes, the direction of a hydraulic pump does matter. A pump’s direction is important because it affects how much force the pump can produce. Pumps are used to move fluids in many different directions and it is important that the direction of the force be matched with the desired application. Pumps with a directional flow can produce more force than those without a directional flow.

How many ways are pumps directional?

There are several different ways a hydraulic pump can be directional. One example is when the pump is mounted on a rotating shaft. This direction can be changed by rotating the shaft.

Another example is when the pump is mounted on a stationary axle. This direction can be changed by turning the axle.

Another example is when the pump is mounted on a moving axle. This direction can be changed by moving the axle.

How do you know what direction a hydraulic pump is facing?

A hydraulic pump can be turned in any direction, depending on the orientation of the valves. If the valves are oriented vertically, then the pump can be turned in a horizontal direction. If the valves are oriented horizontally and the pump is mounted upside-down, then the pump can turn in a vertical direction.

If the valves are oriented horizontally, then the pump can be turned in a horizontal direction.

Why does the direction matter?

One of the most common questions we get at our shop is whether a hydraulic pump is directional or not. And the answer, surprisingly, can depend on the application!

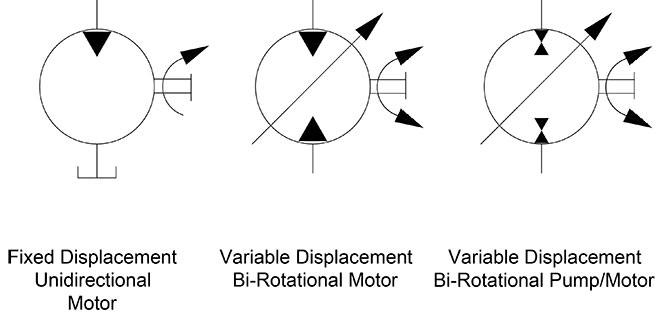

In general, hydraulic pumps are directional. This means that the impeller rotates in one direction only – always moving fluid from the reservoir to the end users. However, this doesn’t always have to be the case. Many industrial and commercial applications require directional pumps, but sometimes it’s more important to have a pump that can flow in both directions.

Let’s take a look at some examples:

Pumps used in water distribution systems are typically directional because water needs to flow from one point to another. Pumps for recycling plants need to move refuse and solids in one direction so they can be processed into new products. And many agricultural pumps use a two-directional design to move water and fertilizer around a farmstead.

The main reason it’s important to know whether a pump is directional or not is because it can affect how much power is needed to operate it and how efficiently it works. If the pump is not directional, then it must be pointed in one specific direction so fluid will flow

Are all pumps directional?

The short answer is: no, not all pumps are directional. In fact, many pumps are non-directional, meaning they can flow in either direction. This is due to the way that the pump works- the pistons move up and down as oil is pumped out of the tank.

When selecting a pump, it is important to determine its intended use. Some pumps are specifically designed for drainage, while others are more suitable for filling up a vehicle with gas.

Pros and Cons of having a directional pump

Hydraulic pumps are directional because the forces exerted on the pump impeller rotate it in one direction. This is beneficial for a few reasons. First, it allows for more consistent fluid flow, which leads to improved performance and longer life. Second, directional pumps are less likely to clog, since particles and other material will be directed away from the pump’s rotors. Finally, directional pumps minimize noise and vibration, making them ideal for high-traffic areas. However, there are also some disadvantages to using a directional pump. First, they can be more expensive than non-directional pumps. Second, they may require more space than a non-directional pump because of their larger size and rotating blades. Finally, directional pumps can be less efficient when used in low-pressure applications or in cold environments.

Conclusion

Yes, hydraulic pumps are directional. This is why they can be used to move fluids in a variety of directions.

For many applications, directional pumps are the best option because they are more consistent and efficient. However, there are also some disadvantages to using a directional pump. First, they can be more expensive than non-directional pumps. Second, they may require more space than a non-directional pump because of their larger size and rotating blades. Finally, directional pumps can be less efficient when used in low-pressure applications or in cold environments.

Are hydraulic pumps directional,please click topkitparts see more