Hydraulic pumps are essential for a variety of applications, from moving heavy objects to pumping water out of wells. Choosing the right type of hydraulic pump can be a daunting task, but with the help of this guide, you’ll be able to make an informed decision.

What is a hydraulic pump?

A hydraulic pump is an engine that uses pressure to move a fluid. Hydraulic pumps are used in many different applications, including construction, water treatment, mining, and automotive repair. Some of the most common types of hydraulic pumps are rotary vane and screw type.

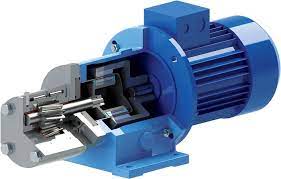

Rotary vane pumps are the most common type of hydraulic pump. They use a series of discs or blades to move the fluid. This type of pump is often used in construction because it is fast and efficient. Screw type hydraulic pumps are similar to rotary vane pumps but they use screws to move the fluid. This type of pump is often used in automotive repair because it is durable and easy to use.

Types of hydraulic pumps

There are many types of hydraulic pumps, and each has its own advantages and disadvantages. Here is a brief overview of the most common types of hydraulic pumps:

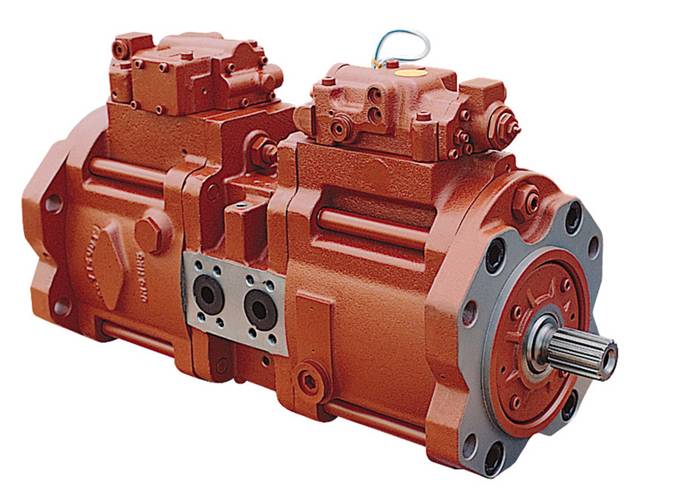

Piston Pump: This type of pump is powered by a piston that moves up and down within a cylinder. This type of pump is relatively simple to operate and is often used in applications where small amounts of fluid are required, such as in hydraulic machines or in industrial processes.

Rotary Pump: This type of pump uses a series of rotary blades to move the fluid. Because this type of pump is more complex than a piston pump, it can be more efficient and faster in terms of operation. Rotary pumps are often used in applications where high volumes of fluid are required, such as in water treatment plants or in manufacturing plants.

Vortex Pump: This type of pump uses a vortex motor to create a rotational motion that transfers energy to the fluid. Because vortex pumps are more efficient than rotary pumps, they are often used in applications where high volumes of fluid are required, such as in water treatment plants or in mining applications.

How hydraulic pumps work

Hydraulic pumps are used in a variety of settings, including mining and oil production. They work by using a cylinder filled with pressurized fluid to move a material or object. The most common type of hydraulic pump is the piston pump, which uses the pressure of the fluid to move the piston.

The best type of hydraulic pump for your needs

There is no one-size-fits-all answer to this question, as the best type of hydraulic pump for a particular application will depend on the specific needs of that application. However, here are some general guidelines to help you choose the right type of hydraulic pump for your needs:

1. Choose a pump with the right horsepower. The size of the hydraulic pump will be based on its horsepower. For example, a small hydraulic pump with a horsepower of 100 can be used in applications where a small amount of pressure is required, such as in agricultural or industrial settings. A larger hydraulic pump with a higher horsepower (such as 300 or 500) can be used in more demanding applications, such as construction or mining.

2. Choose a pump with the right type of fluid delivery system. Hydraulic pumps come in four main types: centrifugal, piston, vane and screw. Each has its own advantages and disadvantages for specific applications:

a. Centrifugal pumps are best suited for liquids that move quickly, such as water or oil. They are also popular choices for small applications that don’t require high pressures or long durations of operation. Centrifugal pumps tend

The advantages of using a hydraulic pump

When it comes to choosing the best type of hydraulic pump for a particular application, there are a few things to consider. Here are four of the most important factors:

1. Capacity: A hydraulic pump’s capacity is important because it determines how much fluid it can move per minute. For example, a pump with a greater capacity can move more water or oil than a smaller pump.

2. Speed: A pump’s speed is also important because it affects how quickly the fluid can be moved. For example, a slow pump will struggle to move fluid quickly enough for many applications.

3. Noise: Finally, noise levels are an important consideration when selecting a pump. Higher noise levels can be disruptive and annoying, particularly in noisy environments such as factories or construction sites.

When selecting a hydraulic pump, it’s important to consider all of these factors in order to find the best option for your specific needs.

The disadvantages of using a hydraulic pump

As hydraulic pumps become more popular, there are many people who are wondering what the best type of hydraulic pump to use is. However, before making a decision, it is important to understand the disadvantages of each type. Here are three of the most common types of hydraulic pumps and their respective disadvantages: rotary vane pumps, screw pumps, and piston pumps.

Rotary vane pumps are typically used in applications where high pressure and high flow rates are required, such as in water or oil pipelines. They have the disadvantage of requiring a large amount of energy to operate, which can lead to increased wear and tear on the pump. Additionally, rotary vane pumps have a high failure rate due to their delicate design. Screw pumps are less expensive than rotary vane pumps and have the advantage of being able to operate at lower pressures. However, they also have a lower flow rate than rotary vanes and require more maintenance due to their gearbox design. Piston pumps are the most expensive type of hydraulic pump but also have the highest flow rate. They have the disadvantage of being unable to reach very high pressures, which can make them unsuitable for some applications.

Compare the types of hydraulic pumps and learn which one is best for your project

When it comes to choosing the best type of hydraulic pump for your project, there are a few things to consider. Here, we’ll compare the different types of hydraulic pumps and help you decide which one is best for your needs.

Piston Pump: A piston pump is a common type of hydraulic pump used in industry and construction. They’re typically small, lightweight and affordable, making them a good option for smaller applications. They have limited capacity and require frequent maintenance, but they’re usually reliable.

Valve-Pump: A valve-pump is similar to a piston pump, but has two main advantages over them. First, they have higher capacity than piston pumps. This means they can handle larger projects with less frequent maintenance required. Second, they’re able to operate using lower pressure than piston pumps, which makes them more efficient.

Vane Pump: A vane pump is a type of hydraulic pump that uses wings or vanes to move the fluid. They’re often more expensive than other types of pumps, but they offer several advantages over other types of pumps. First, they have greater flow rates than other types of pumps. This means they can handle larger projects with less energy expenditure. Second,

How to Choose the Right Type of Hydraulic Pump for Your Application

When choosing the right type of hydraulic pump for your application, there are a few things to consider. Firstly, the type of duty cycle required by the application will dictate the type of pump that is most suitable. Secondly, the type and size of the fluid being pumped will also influence which type of pump is best. Finally, the cost and availability of different types of pumps will determine which one is chosen.

The three main types of hydraulic pumps are reciprocating, rotary and staged hydraulic pumps. Reciprocating pumps are typically used for low-to-medium duty cycles and can be found in both small and large sizes. Rotary pumps are typically used for high-to-very high duty cycles and can be found in smaller sizes only. Staged hydraulic pumps are designed for applications that require multiple stages of pressure or flow. They are typically more expensive than other types of pumps but are well suited for applications that need very high pressures or flows.

The type of duty cycle required by the application will dictate the type of pump that is most suitable. For example, a reciprocating pump may be more suitable for applications with medium duty cycles while a rotary pump may be better suited for applications with high duty cycles

Conclusion

There are many types of hydraulic pumps on the market, and it can be difficult to decide which one is best for your specific needs. In this article, we will discuss the different types of hydraulic pumps and their benefits and drawbacks. We will also provide you with a list of factors to consider when choosing a hydraulic pump, so that you can make an informed decision about which one is right for you. Thanks for reading!

What is the best type of hydraulic pump,please click topkitparts see more