It can be difficult to know exactly how much hydraulic flow your equipment needs to operate effectively. In this article, we will provide you with a guide on how to measure hydraulic flow and what factors can affect it. By following these tips, you will be able to ensure that your equipment is working at its best and able to meet your needs.

What is Hydraulic Flow?

Hydraulic flow is the rate at which fluid is discharged from a hydraulic pump. The higher the flow, the faster the fluid can move.

Hydraulic pumps are used to move fluids, such as water, oil, and gas. They work by using a pump impeller to create a flow of fluid.

How Hydraulic Flow Works

When you turn on the water faucet, the water pressure pushes water through the pipe. This same pressure is used to move oil and gas through pipelines. The size of the pipe and the pressure determine how much flow is needed.

Hydraulic fluid is a type of oil or gas that is used to move the fluid. This fluid is a mixture of water, oil, and gas. When you turn on the water faucet, the pressure in the pipe moves the hydraulic fluid through the pipe. The same pressure is used to move oil and gas through pipelines.

How Hydraulic Flow Calculations are made

As hydraulic flow is an essential part of many industrial processes, it is important to have an accurate understanding of how hydraulic flow calculations are made. In this blog post, we will discuss the different methods that are used to calculate hydraulic flow. We will also look at some of the factors that can affect the accuracy of these calculations.

The first step in calculating hydraulic flow is to determine the system’s total flow rate. This can be done by measuring the input and output volumes of the system, or by estimating the flow rate based on the system’s operational parameters. Once the total flow rate has been determined, the next step is to determine the system’s hydraulic head. This can be done by measuring the elevation difference between the input and output points, or by estimating the head based on the system’s operational parameters.

Once the hydraulic head has been determined, it can be used to calculate various fluid properties, such as mass flow (MFL), volumetric flow (VFL), and pressure drop. Additionally, head and discharge volumes can be calculated using Bernoulli’s equation. Finally, any friction losses can be estimated based on these volumes and properties.

While these are all common methods for calculating hydraulic flow, there are a number of factors that can affect its accuracy. For example, system geometry can affect how quickly liquid flows through a pipe or valve, which can impact how quickly head is reached and how much pressure is lost along the way. Additionally, operational parameters may change over time, which could lead to inaccurate estimates of head and discharge volumes.

How to Increase Hydraulic Flow

Hydraulic fluid is a very important part of any hydraulic system. It helps to move the pistons and valves that control the flow of water, oil, or other fluid through the system. Hydraulic fluid can be used in a variety of applications, including pumps, engines, and HVAC systems.

It’s important to understand how much hydraulic flow your system needs in order to function properly. The amount of flow depends on the application and the type of hydraulic fluid used. Here are some factors to consider:

Piston Type and Size

The size and type of pistons used determine how much hydraulic pressure is required to move them. Pumps use smaller pistons that require less pressure than engines or HVAC systems. In general, pumps need less pressure than other types of applications.

Pressure Rating

All hydraulic systems have a pressure rating. This is simply the maximum amount of pressure that the system can withstand before it fails. Systems with a higher pressure rating require more hydraulic fluid to operate than systems with a lower rating.

Flow Rate

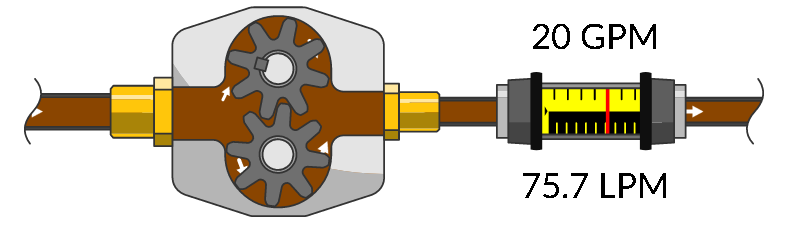

The flow rate is the amount of fluid per minute that passes through the system. The greater the flow rate, the greater the

Calculating Hydraulic Flows in Different Calibrations

Hydraulic flow is a critical component of hydraulic systems. By knowing the required flow, you can ensure that your system is functioning correctly and meets your needs. In this article, we will explore how to calculate hydraulic flows in different calibrations.

Calculating hydraulic flows in various calibrations can be a complex process. However, with the help of a few simple formulas, you can easily calculate the required flow for your system. Let’s take a look at each calibration and see how to calculate its specific flow requirement.

First, let’s consider pressurized hydraulic systems. These systems use fluids that are under pressure to perform their functions. Because of this pressure, hydraulic systems require a higher flow rate than non-pressurized systems. To find the required flow rate for a pressurized hydraulic system, you first need to determine the system’s operating pressure (in psi). You can do this by referencing your system’s specifications or by using an online pressure calculator. Once you have the operating pressure, you can use the following formula to find the required flow rate:

Required Flow Rate = Operating Pressure x 0.714

Next, we’ll look at unpressurized hydraulic

Why should I consider H2O hydraulic flow?

Hydraulic flow is an important consideration when designing or repairing a hydraulic system.

There are several factors to consider when choosing hydraulic flow. These include the type of hydraulic system being used, the application, and the required performance.

HO hydraulic flow is a popular choice for hydraulic systems in industrial applications. It is also a common choice for hydraulic systems used in construction and engineering.

HO hydraulic flow is ideal for applications that require high reliability and low downtime. This flow type is also suitable for systems that require high throughput and low noise levels.

If you are considering HO hydraulic flow for your next project, be sure to contact a qualified contractor. They will be able to help you determine the best option for your needs.

What is the Difference Between Static and Hydraulic Flow?

When it comes to hydraulic flow, there is a big difference between static and hydraulic. Static flow refers to the rate of flow that is constant throughout the entire cycle. Hydraulic flow, on the other hand, refers to the rate of flow that changes over time. This means that the amount of hydraulic flow you need will depend on the type of hydraulic system you are using.

Conclusion

Hydraulic flow is an important parameter for many irrigation systems, and it can be difficult to determine the necessary amount without proper equipment or a calibration procedure. In this article, we will discuss some of the key factors that affect hydraulic flow and how you can use them to calculate your system’s required amount. Armed with this information, you should be able to properly size your irrigation system and optimize its performance.

How much hydraulic flow do I need,please click topkitparts see more