How to adjust hydraulic pump pressure ? In hydraulic systems, the proper adjustment of hydraulic pump pressure is crucial for optimal system performance and efficiency. Manual adjustment of hydraulic pump pressure is often necessary in various situations, such as when automatic adjustment is not possible or when system requirements change. Therefore, it is essential to understand how to manually adjust hydraulic pump pressure in order to maintain the performance of hydraulic systems.Hydraulic systems are commonly used in various industrial applications, including manufacturing, construction, and transportation. In these applications, hydraulic systems rely on the hydraulic pump to generate pressure and flow to power the system’s components, such as hydraulic cylinders, motors, and valves. Therefore, ensuring proper hydraulic pump pressure adjustment is critical to maintaining the performance and efficiency of hydraulic systems.

The purpose of this article is to provide step-by-step instructions for manually adjusting hydraulic pump pressure. We will cover the importance of hydraulic pump pressure adjustment, why manual adjustment is necessary, the steps for manually adjusting hydraulic pump pressure, testing hydraulic pump performance, safety considerations, and the benefits of proper hydraulic pump pressure adjustment. By the end of this article, you will have a clear understanding of how to manually adjust hydraulic pump pressure and how it can benefit your hydraulic system’s performance and efficiency.

Understanding Hydraulic Pump Pressure Adjustment

Hydraulic pump pressure adjustment is a crucial process that helps ensure hydraulic systems are working efficiently. In hydraulic systems, pressure is a key factor that affects the system’s overall performance. Pressure adjustments are necessary for a variety of reasons, including system optimization, maintaining equipment efficiency, and meeting operational requirements.

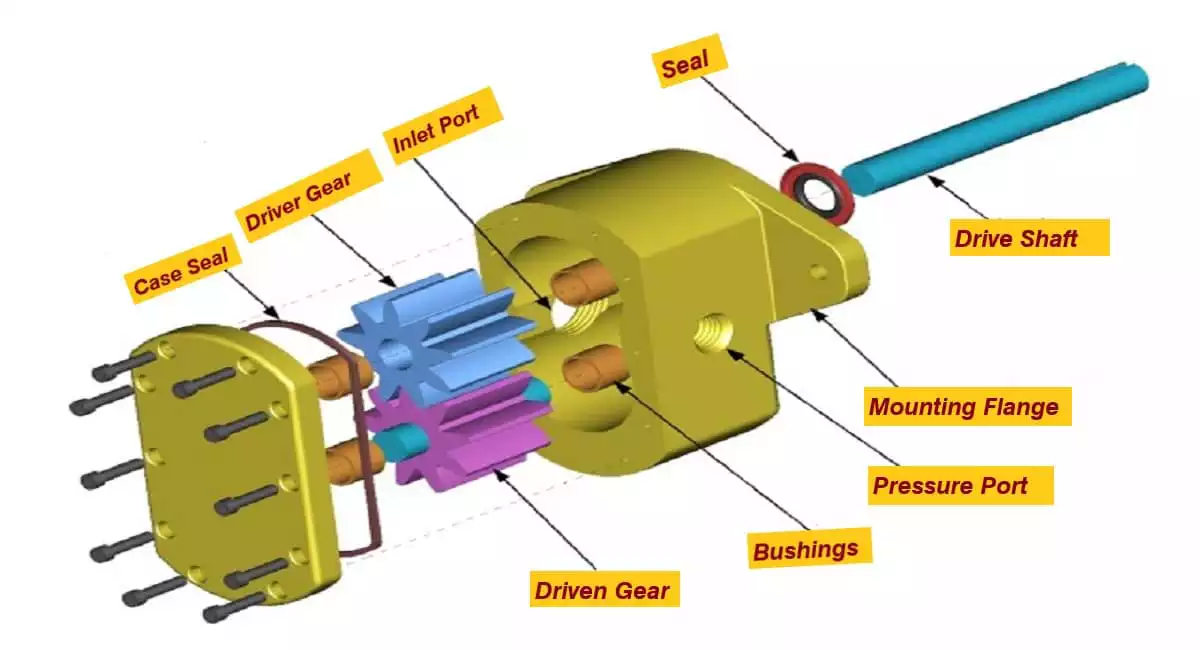

Hydraulic pump pressure adjustment involves making changes to the hydraulic system’s pressure levels by adjusting the hydraulic pump. A hydraulic pump is responsible for generating hydraulic pressure, which is used to power various hydraulic components within the system. Pressure adjustments can be made manually or automatically, depending on the system’s design and requirements.

Understanding the components of hydraulic pump pressure adjustment is important for effective pressure adjustment. These components include the hydraulic pump, hydraulic pressure gauge, pressure relief valve, and hydraulic control valve. The hydraulic pump generates hydraulic pressure, which is measured by the hydraulic pressure gauge. The pressure relief valve releases excess pressure to protect the hydraulic system from damage, while the hydraulic control valve regulates the flow and direction of hydraulic fluid.

Why Manually Adjust Hydraulic Pump Pressure?

In hydraulic systems, the pressure of the hydraulic fluid is a critical factor that determines the performance of the system. The hydraulic pump is responsible for generating the necessary pressure to drive the system, and any variations in pressure can cause performance issues or even damage to the system. In some situations, the hydraulic pump pressure may need to be manually adjusted to achieve optimal performance or to compensate for changing conditions.

There are several benefits to manually adjusting hydraulic pump pressure. Firstly, manual adjustment allows for fine-tuning of the pressure to achieve optimal system performance. Automatic pressure adjustment systems may not be sensitive enough to detect minor pressure changes or compensate for variations in system load, which can result in suboptimal system performance. Secondly, manual adjustment can be necessary in situations where automatic pressure adjustment systems are not available or have failed. In these situations, manual adjustment may be the only option to maintain system performance.

Manual adjustment differs from automatic adjustment in that it requires the operator to physically adjust the pressure setting on the hydraulic pump. This involves understanding the system requirements and the characteristics of the hydraulic pump, as well as following the correct procedures to avoid damage to the system or injury to the operator.

Steps for Manually Adjusting Hydraulic Pump Pressure

Manual adjustment of hydraulic pump pressure requires a few preparatory steps to ensure that the adjustment process goes smoothly and safely. Here are the general steps to follow when manually adjusting hydraulic pump pressure:

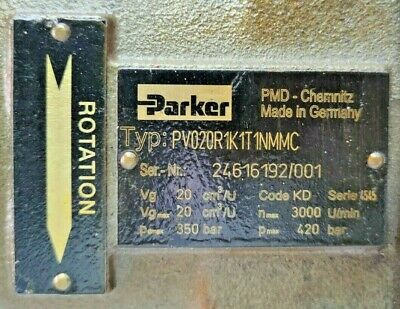

- Identify the hydraulic pump: Before adjusting the hydraulic pump pressure, identify the pump and locate the pressure adjustment mechanism. This will usually be a pressure relief valve located near the pump.

- Check the system pressure: Measure the current system pressure before adjusting the hydraulic pump pressure. This will give you a reference point for the desired pressure setting.

- Release system pressure: To prevent accidents, it is important to release the system pressure before making any adjustments. This can be done by opening the hydraulic valve or actuating the hydraulic system.

- Remove the protective cap: The pressure adjustment mechanism will usually be covered by a protective cap. Remove this cap to access the mechanism.

- Use a pressure gauge: Connect a pressure gauge to the hydraulic system to monitor the pressure during the adjustment process. This will allow you to accurately set the desired pressure.

- Turn the pressure adjustment screw: The pressure adjustment screw is the mechanism that controls the hydraulic pump pressure. Using a screwdriver or other suitable tool, turn the screw clockwise to increase the pressure or counterclockwise to decrease it.

- Monitor the pressure gauge: While turning the adjustment screw, keep an eye on the pressure gauge to ensure that the pressure is increasing or decreasing to the desired level. Make small adjustments to avoid overcorrecting and causing system damage.

- Lock the adjustment screw: Once the desired pressure has been reached, lock the adjustment screw in place with a locknut or similar mechanism.

- Check the system pressure: Finally, check the system pressure again to ensure that it has reached the desired level. If necessary, make additional adjustments until the desired pressure is achieved.

Types of Compensating Valves and Their Advantages in Hydraulic Control

It is important to note that the above steps are general guidelines and that specific instructions may vary depending on the type of hydraulic pump and the hydraulic system in use. It is also important to follow all safety precautions and use appropriate personal protective equipment during the adjustment process.

Setting Hydraulic Pump Pressure

Once you have determined the desired hydraulic pump pressure, you can begin the process of manually adjusting the pump pressure. Follow these steps:

- Locate the pressure adjustment valve: Depending on the type of hydraulic pump, the pressure adjustment valve may be located on the pump or elsewhere in the hydraulic system. Consult the pump manual or system schematics to locate the valve.

- Determine the current pressure setting: Use a pressure gauge to measure the current pressure setting. This will provide a baseline for adjusting the pressure.

- Adjust the pressure: Use the pressure adjustment valve to increase or decrease the pressure as needed. Turn the valve clockwise to increase the pressure and counterclockwise to decrease it. Make small adjustments, testing the pressure after each adjustment, until the desired pressure is reached.

- Check the pressure gauge: After making adjustments, check the pressure gauge to ensure that the desired pressure has been achieved. If not, continue making small adjustments until the desired pressure is reached.

- Lock the adjustment valve: Once the desired pressure has been achieved, lock the adjustment valve in place to prevent further adjustments.

- Record the new pressure setting: Make a record of the new pressure setting for future reference.

It is important to note that each hydraulic pump is unique, and the pressure adjustment process may differ slightly depending on the pump model and manufacturer. Always consult the pump manual and follow the recommended procedures for pressure adjustment. Additionally, it is important to ensure that the pressure gauge used for testing is accurate and calibrated correctly. A faulty pressure gauge can lead to inaccurate pressure readings and potentially dangerous hydraulic system performance.

Testing Hydraulic Pump Performance

After manually adjusting the hydraulic pump pressure, it is important to test the performance of the hydraulic pump to ensure that it is working optimally. There are a few different tests that can be conducted to determine the performance of the hydraulic pump.

The first test that should be conducted is a flow rate test. This test measures the flow rate of the hydraulic pump to determine if it is producing the required flow rate for the hydraulic system. To conduct a flow rate test, a flow meter is attached to the outlet of the hydraulic pump, and the hydraulic pump is run at the required speed. The flow rate is then measured and compared to the required flow rate for the hydraulic system. If the flow rate is not within the required range, adjustments may need to be made to the hydraulic pump pressure.

The second test that should be conducted is a pressure test. This test measures the pressure produced by the hydraulic pump to ensure that it is within the required pressure range for the hydraulic system. To conduct a pressure test, a pressure gauge is attached to the outlet of the hydraulic pump, and the hydraulic pump is run at the required speed. The pressure is then measured and compared to the required pressure range for the hydraulic system. If the pressure is not within the required range, adjustments may need to be made to the hydraulic pump pressure.

The third test that should be conducted is a temperature test. This test measures the temperature of the hydraulic fluid to ensure that it is within the required temperature range for the hydraulic system. To conduct a temperature test, a temperature gauge is attached to the hydraulic fluid, and the hydraulic pump is run at the required speed. The temperature is then measured and compared to the required temperature range for the hydraulic system. If the temperature is not within the required range, adjustments may need to be made to the hydraulic pump pressure.

Once these tests have been conducted, any issues with the hydraulic pump performance can be identified and addressed. If the hydraulic pump is performing optimally, it can be put back into operation. If adjustments need to be made, the hydraulic pump pressure can be manually adjusted again, and the performance tests can be repeated until the hydraulic pump is working as required.

Mastering Hydraulic Pump Control: Tips and Tricks for Optimal Performance

In addition to performance testing, it is important to regularly monitor the hydraulic pump to ensure that it continues to operate optimally. Regular maintenance and inspection can help to identify any issues before they become major problems, and can help to ensure that the hydraulic system operates efficiently and effectively.

Safety Considerations for Manually Adjusting Hydraulic Pump Pressure

When manually adjusting hydraulic pump pressure, it is essential to ensure that all safety measures are taken to prevent accidents and injuries. Hydraulic systems operate under high pressure, which can cause severe injuries or even death if not handled with care. Below are some safety considerations that should be taken into account when manually adjusting hydraulic pump pressure:

- Wear appropriate personal protective equipment (PPE): Before working on hydraulic systems, personnel should wear appropriate PPE, including safety glasses, gloves, and steel-toed boots. This protective gear can help prevent injuries in case of an accident.

- Release the pressure: Before making any adjustments, it is crucial to release the pressure from the hydraulic system. This can be done by turning off the pump and opening the bleed valve to release any trapped pressure.

- Use proper tools: Only use proper tools that are designed to handle hydraulic systems when adjusting the pump pressure. This ensures that the tools can withstand the high pressure and reduce the risk of accidents.

- Never use body parts to check for leaks: It is crucial to never use any body parts to check for leaks in hydraulic systems. This can lead to serious injuries or even amputations in case of an accident.

- Follow proper procedures: Always follow the proper procedures for adjusting the hydraulic pump pressure. This includes ensuring that the system is depressurized, using appropriate tools, and testing the system after the adjustment is made.

- Proper training: All personnel working on hydraulic systems should receive proper training on the safe handling of hydraulic systems, including how to manually adjust pump pressure.

- Maintain the system: Regular maintenance of the hydraulic system can help prevent accidents and injuries by ensuring that all components are working correctly.

By taking these safety considerations into account, businesses can help prevent accidents and injuries when manually adjusting hydraulic pump pressure. It is crucial to ensure that all personnel working on hydraulic systems are trained on proper safety measures and procedures to prevent accidents and injuries.

Conclusion

Proper hydraulic pump pressure adjustment is critical to the smooth operation of hydraulic systems. By manually adjusting hydraulic pump pressure, you can optimize the system for specific applications, improve energy efficiency, and reduce the likelihood of equipment failure. In this article, we have provided step-by-step instructions for manually adjusting hydraulic pump pressure, but it is important to note that this should only be done by trained professionals.

In conclusion, knowing how to manually adjust hydraulic pump pressure is essential for businesses that use hydraulic systems. By following the steps outlined in this article and adhering to safety guidelines, you can ensure that your hydraulic systems are operating optimally and efficiently. Proper hydraulic pump pressure adjustment can help businesses reduce maintenance costs, extend the life of their equipment, and increase productivity. Therefore, we urge businesses to train their personnel on manual hydraulic pump pressure adjustment and to make it an integral part of their maintenance and optimization processes.