If you’ve ever seen a gear pump in action, you know that it’s a bit of a marvel – a rotating wheel with blades that push water through a pipe. Now, here’s a question for you: can you run the gear pump backwards?

The answer is… kind of! While it’s not technically possible to run a gear pump backwards, you can certainly try it – and if you’re careful, you might be able to get the pump going in the opposite direction without tearing anything apart. Just be sure to take all necessary precautions, including wearing safety goggles and gloves, and making sure that the area you’re working in is well-ventilated.

What is a gear pump?

A gear pump is a device that uses gears to create a rotational motion. The gears are usually driven by an electric motor, and the pump can be used to move liquids or gases.

The gear pump can also be used to create pressure in a fluid system. By reversing the direction of the gears, the pump can generate negative pressure, which is useful for cleaning and removing contaminants from a system.

How does a gear pump work?

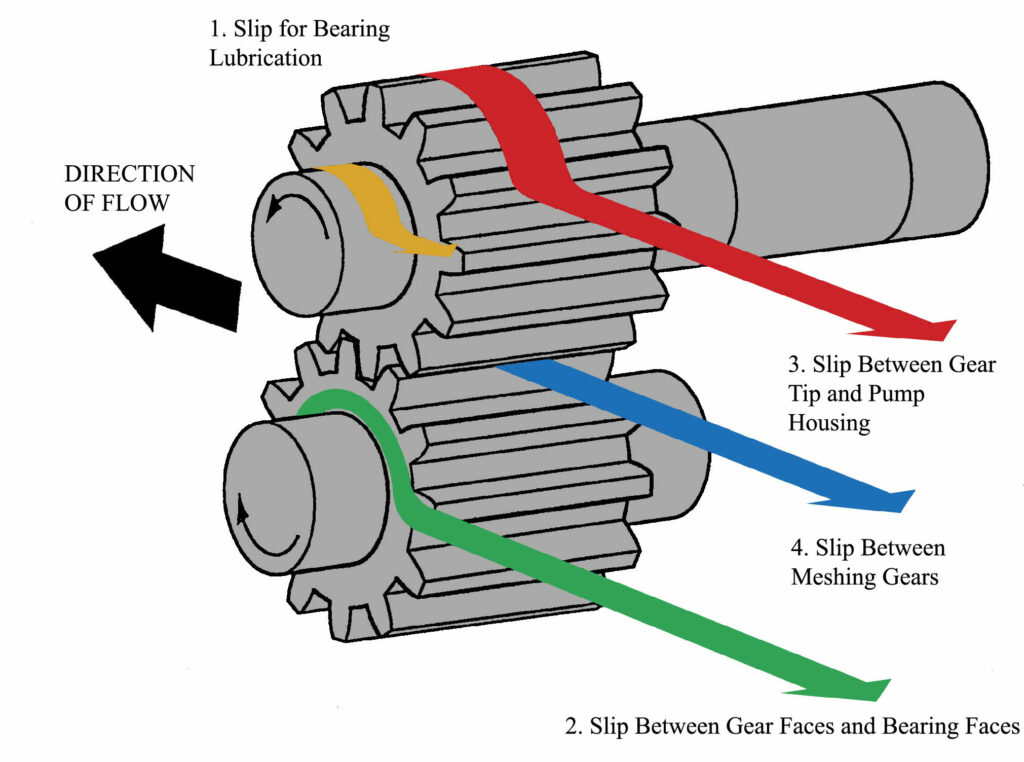

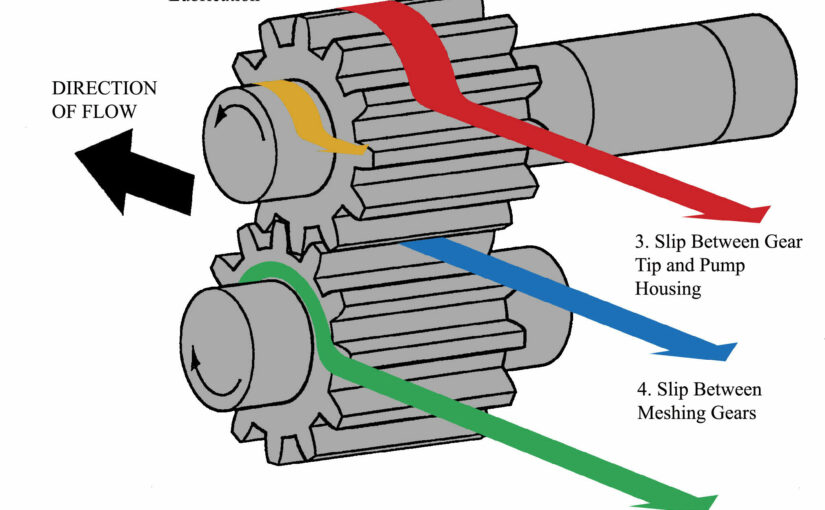

Gear pumps are used in a variety of industrial and commercial settings to move fluid, such as hydraulic oil and water for cooling towers. They work by rotating a series of gears so that the output shaft rotates in the opposite direction of the input shaft. This causes the pump to create a flow of fluid from the input to the output.

But how does a gear pump work if you turn it the other way?

The reverse gear mechanism uses a set of meshing gears to convert direct drive into reverse drive. As the gears rotate, they cause the output shaft to rotate in the opposite direction of the input shaft. This causes the pump to create a flow of fluid from the output to the input.

What are the Different Gears of a Gear Pump?

A gear pump is a machine that uses gears to move fluid or air. The different gears allow the pump to run in either direction. When you run a gear pump backwards, the gears turn so slowly that they can’t create enough force to move the fluid or air.

The four gears of a gear pump are:

1. The input gear. This is the smallest gear and it’s on the bottom of the pump. It helps turn the larger gears.

2. The output gear. This is the largest gear and it’s on the top of the pump. It helps move the fluid or air.

3. The reverse gear. This is a small gear that’s inside the output gear. When you run the pump backwards, this gear turns so quickly that it creates enough force to move the fluid or air.

4. The clutch. This is a mechanism that helps keep the gears turning when you run the pump backwards.

How to Flush a Gear Pump

If your gear pump isn’t working, it’s probably because something is blocking the flow of oil. In most cases, this means that some object is wedged in between the casing and the pump shaft. To free the pump, you’ll need to flush it with oil. Here’s how:

1. Turn off the power to the gear pump.

2. Remove the cap from the end of the pipe that leads to the gear box.

3. Pour oil into the pipe until it starts flowing out of the end opposite the gear box.

4. Close the end of the pipe leading to the gear box and turn on the power to the gear pump.

5. The oil will force any objects obstructing its path out of the pump and it will work again.

Reasons to Flush a Gear Pump

A gear pump can be run backwards to drain water or oil from a gearbox or engine. Here are four reasons to flush a gear pump:

1. To remove water or oil contamination.

2. To clear a jammed gearbox.

3. To lubricate a gearbox or engine.

4. To prevent over-torqueing of gears in the gearbox or engine.

Why is it Impossible to Reverse a Gear Pump?

Gear pumps work by spinning a shaft with gears on it. The shaft moves the pump’s impeller, which sucks water or oil out of the well or reservoir. When you want to put the pump back in reverse, you have to spin the shaft the opposite way and release the impeller. If you tried to do this with a gear pump sitting on your driveway, you would quickly realize that it’s not possible! Gears don’t work that way!

There are actually two main reasons why it’s impossible to reverse a gear pump:

1) The gears meshed together so that they can’t turn in the opposite direction.

2) The shaft itself is spinning inside the gear box, which makes it difficult to get it started in the opposite direction.

Alternatives to running a pump backwards

Gear pumps are occasionally used to push water uphill, but this can be dangerous and is not recommended. If you must use a gear pump to move water, there are several alternatives that you should consider.

One option is to use a pressure washer. This will force the water through the pump much faster than using a regular pump, but it can also be dangerous if you are not careful.

Another option is to use a jet pump. These pumps are specifically designed to move water quickly and efficiently. However, they can be expensive and may not be suitable for all applications.

If you only need to move small amounts of water, you can use a hand pump. These pumps can be fairly simple to operate and are usually quite portable.

Conclusion

Gear pumps are essential for a number of different tasks in the automotive repair and maintenance world. However, using them backwards can cause damage to the pump and even lead to a motor seizure. If you’re ever in doubt as to whether or not your gear pump can be run in reverse, it’s best to consult with an expert before attempting the task yourself.

Can you run a gear pump backwards,please click topkitparts see more

One thought on “Can you run a gear pump backwards?”