Have you ever wondered if you could power a hydraulic pump with an electric motor? In this article, we will explore just that and see if it is possible. By the end of the article, you should be able to determine if an electric motor would be a good choice for powering your hydraulic pump.

What is a hydraulic pump?

A hydraulic pump is a type of electric motor that uses pressurized fluid to move parts or objects. These motors are used in a variety of applications, including in automobiles, construction, farming and mining. Some electric pumps use oil as the pressurized fluid, while others use water.

HYDRAULIC PUMP – an electric motor used for moving parts by pressurizing fluid.

How does a hydraulic pump work?

A hydraulic pump is a machine that uses pressurized fluid to move objects. The pressurized fluid comes from an electric motor, which turns the blades on the pump. This motion creates a flow of pressurized fluid through the pump, which can then move objects.

Hydraulic pumps are commonly used in devices like cars and planes. They are also used in watermills and other machines that need to move objects using a fluid.

What are the different types of hydraulic pumps?

There are many types of hydraulic pumps, but all of them use pressurized fluid to move objects or fluids. The most common types of hydraulic pumps are electric motors driven by hydraulics.

Electric motors offer several advantages over traditional hydraulic systems. First, electric motors are quieter and cooler than traditional hydraulic systems. Second, electric motors can be more efficient because they use less power to move the same amount of fluid. Finally, electric motors can be operated from a remote location, making them ideal for applications where maintenance is difficult or impossible.

How to build an electric motor

Building an electric motor is a great way to power your hydraulic pump. You can find instructions online or in books on how to build an electric motor. Make sure you have all the necessary parts and tools before you start.

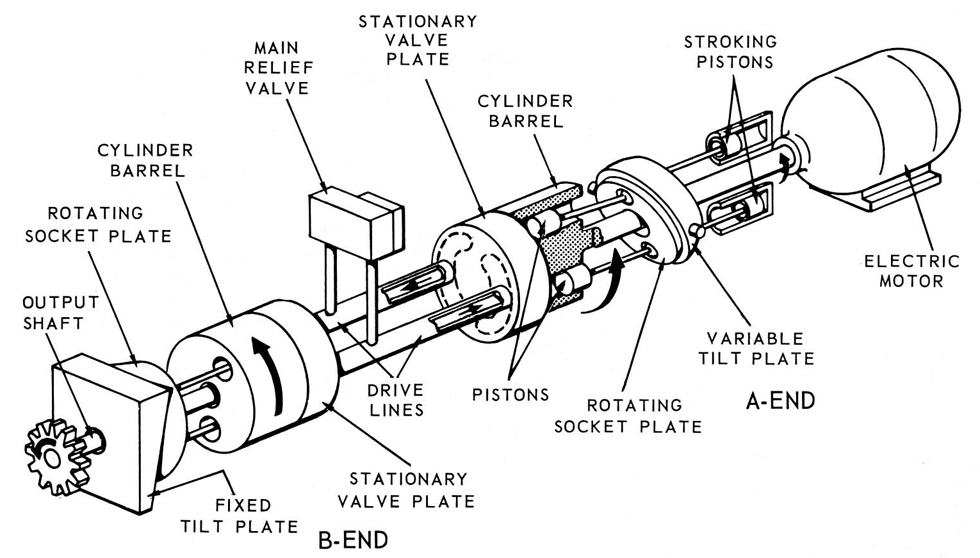

Hydraulic pumps and motors

Electric motors can be used to power hydraulic pumps. This is because electric motors are able to produce a higher level of torque than standard motors. This means that they can be used to rotate the pump faster, which results in greater flow rates.

Hydraulic pumps can be powered by either electric or gas motors. When choosing a power source for your hydraulic pump, it is important to consider the size and type of motor that will be required. Electric motors are usually smaller and more versatile than gas motors, but they tend to produce less torque. Gas motors are usually larger and produce more torque, but they can be more expensive to purchase and maintain.

How do you connect an electric motor to a hydraulic pump?

There are a few ways to connect an electric motor to a hydraulic pump. One way is to use a belt drive. Another way is to use a shaft drive.

If you use a belt drive, you would first need to connect the motor to the belt. Then, you would need to connect the belt to the pump.

How to make a hydraulic pump with an electric moto

When it comes to powering hydraulic pumps, you have a few options. You can use an electric motor, gasoline engine, or diesel engine. However, the electric motor is the most popular choice because it’s more efficient and doesn’t produce any harmful emissions. Here’s how you can make a hydraulic pump with an electric motor:

1) Choose the right electric motor. You need an electric motor that can generate enough power to run your pump. Some of the best options include industrial motors and lawnmowers.

2) Install the motor. Install the electric motor in your hydraulic pump according to manufacturer instructions. Make sure that the wire connections are secure and that the motor is properly grounded.

3) Connect the hoses. Connect the hoses from your pump to the motor. Make sure that you connect them correctly so that the pressure from your pump flows into the motor and not vice versa.

4) Test the pump. Once all connections are made, test your pump by running it for a few minutes in order to ensure that everything is working correctly.

Why Would I Want to Run a Hydraulic Pump with an Electric Motor?

There are a few reasons why someone might want to run a hydraulic pump with an electric motor. For example, if the electric motor is smaller and less powerful than the hydraulic pump, the electric motor can be used to power the pump instead of using the more powerful engine. Additionally, electric motors are often quieter than gasoline or diesel engines, which can be useful in areas with noise restrictions. Additionally, electric motors have a longer lifespan than gasoline or diesel engines, so they may be a better option for some applications.

As always, please consult your local authorities or professionals before making any decisions about powering your equipment with an electric motor.

What Are the Advantages of Running a Hydraulic Pump with an Electric Motor?

Running a hydraulic pump with an electric motor can be advantageous for a couple of reasons. For one, electric motors are typically more efficient than traditional hydraulic motors, which can result in a reduction in fuel consumption. Additionally, electric motors are often less noisy than hydraulic motors and they offer greater flexibility when it comes to installation.

What Are the Disadvantages of Running a Hydraulic Pump with an Electric Motor?

There are a few disadvantages to running a hydraulic pump with an electric motor. First, the electric motor can only produce a certain amount of power, so if the hydraulic pump requires more power than the electric motor can provide, the pump will not work. Additionally, electric motors are not very efficient when it comes to operating a hydraulic pump, so the overall efficiency of the operation will be lower than if the pump were run with a traditional engine.

Conclusion

Yes, you can run a hydraulic pump with an electric motor. You will need to make sure that the electric motor is rated for the task at hand and that the hydraulic pump is compatible with the electric motor. Additionally, you will need to ensure that there are no sparks or fire in between the two devices.

Can you run a hydraulic pump with an electric motor, please click topkitparts see more