hydraulic motors are used to create motion and power by using pressurized fluid. They come in a variety of shapes and sizes, and can be used for a variety of applications, including pumping water, operating machinery, and more. In this article, we’ll walk you through the basics of how a hydraulic motor works, and help you select the best one for your needs.

What is a hydraulic motor

A hydraulic motor is a type of electric motor that uses the power of pressurized fluid to turn a shaft. A pump is an example of a machine that uses hydraulics to move fluid.

Hydraulic motors are most commonly used in applications where large amounts of force are needed, such as in construction, mining, and agricultural machinery. They are also used in cars and other vehicles to power the actuators (those that move the wheels) and other mechanical components.

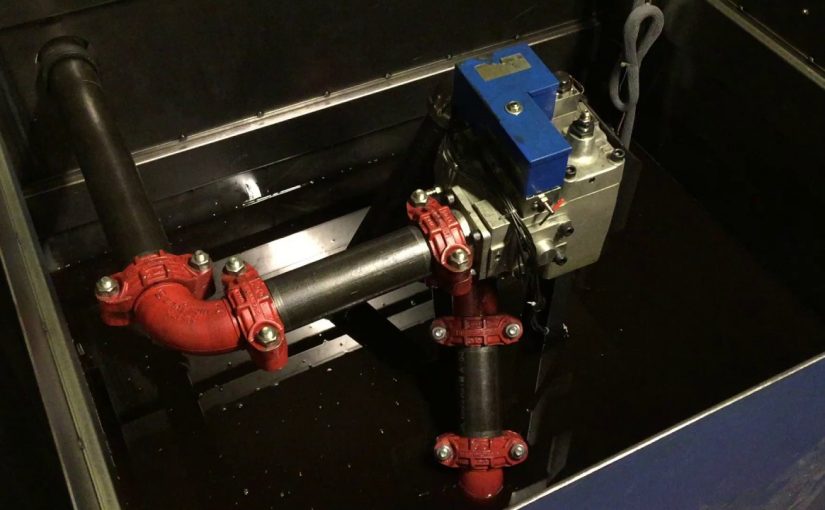

A hydraulic motor is made up of three main components: a pump, a motor housing, and a gearbox. The pump circulates the pressurized fluid through the motor housing and gearbox. The gearbox provides the necessary gearing to turn the shaft.

The pressurized fluid inside the motor housing creates a rotating force that powers the motor. This force can be used to move objects or perform other tasks.

How does a hydraulic motor work

A hydraulic motor is a type of engine that uses the power of pressurized fluid to turn an axle. The fluid is typically oil or water, and it is forced through a series of pistons to turn the axle. This process creates a lot of pressure, which can be used to power other devices.

Hydraulic motors work by using the pressure created by the fluid to turn the axle. The pressure is typically created by using a pump to force oil or water through a series of pistons. This process creates a lot of pressure, which can be used to power other devices.

Disadvantages of using a hydraulic motor as a pump

A hydraulic motor can be used as a pump, but there are several disadvantages to using one. First of all, a hydraulic motor is very powerful, and can easily overheat if used for too long. Secondly, a hydraulic pump is not particularly efficient. Finally, a hydraulic pump is not always reliable, and can be difficult to repair if something goes wrong.

Advantages of using a hydraulic motor as a pump

There are many advantages to using a hydraulic motor as a pump. First, they are quiet and efficient, which can be helpful in areas withsensitive acoustic noise levels. Additionally, a hydraulic motor is reliable and oftenhas a longer lifespan than other types of pumps. Finally, a hydraulic motor can be customized for specificapplication needs, making it an ideal choice for pumps that require high precision ortremendous power.

Can you use a hydraulic motor as a pump?

If you have a hydraulic motor that can operate at a higher than normal speed, you may be able to use it as a pump. A hydraulic motor is an engine that uses pressurized fluid to power the movement of a piston or rotor. When used as a pump, the high-speed motion of the motor can create enough force to move water or other fluid objects.

Keep in mind that using a hydraulic motor as a pump can create some significant risks. For example, if the motor fails, the pressurized fluid could explode and cause serious damage. Additionally, if the pump is not properly installed or maintained, it could overheat and fail catastrophically. If you are considering using a hydraulic motor as a pump, be sure to consult with an expert prior to implementation.

How to choose the right hydraulic motor for your application?

Choosing the right hydraulic motor for your application can be a daunting task, but with the help of a few simple guidelines it can be made much easier. The first step is to determine the required power output, which is typically determined by the project size and the desired speed. Once that information is known, other factors such as stroke length, type of piston and discharge port can be considered.

One important factor to consider when selecting a motor is its duty cycle. A motor’s duty cycle refers to how often it is activated, and typically varies depending on the application. For example, a motor used in construction may have a high duty cycle while one used in agricultural production may have a lower duty cycle. This is important to consider because it will affect both the power and longevity of the motor.

Overall, taking all of these factors into account will help ensure that the correct hydraulic motor is selected for the job at hand.

Conclusion

The short answer is yes, you can use a hydraulic motor as a pump. However, there are certain considerations that need to be made before doing so.

First and foremost, make sure that the hydraulic motor you choose is capable of pumping the amount of fluid required.

Secondly, ensure that the pump head is compatible with the hydraulic motor you have chosen.

Thirdly, understand how to operate the pump and keep track of your fuel levels in order to avoid running out of energy too soon.

Fourthly, be aware of any environmental factors that could impact the performance of your pump (e.g., extreme weather conditions).

Finally, always wear protective gear when using a hydraulic motor as a pump (e.g., safety goggles and gloves) in order to minimize potential injuries.