Hydraulic gear pumps are used in a variety of applications, including agriculture, mining, and manufacturing. In this article, we’ll learn about the workings of a hydraulic gear pump and how it can be used to power various machines.

The basic principle behind a hydraulic gear pump is simple. The pump’s gears are connected to a rotating shaft and a discharge pipe. As the gears rotate, they create a fluid flow that can be used to power various machines.

The fluid that flows through the pump is typically water or oil. When the pump is activated, it causes the fluid to move rapidly through the pipe and out into the surrounding area. This process can be used to power various machines.

What is a hydraulic gear pump?

A hydraulic gear pump is a machine that uses the power of hydraulics to move materials. The components of a gear pump work together to create movement.

The crankshaft spins the gears, which in turn transfer power to the pistons. The pistons move the fluid through the pump and it moves the material.

Gear pumps are used in many different applications, including mining, construction, and manufacturing. They are also used in water treatment and agriculture.

How does a hydraulic gear pump work?

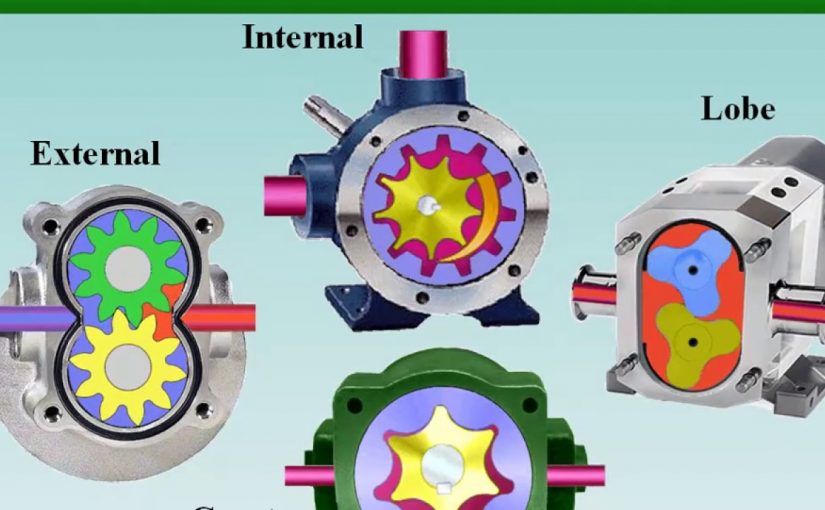

A gear pump is a device used to transfer rotational power from an input shaft to an output shaft. Gears are used because they allow the rotational motion to be transferred in a continuous manner, without any sudden changes in speed. In a typical gear pump, the input shaft is connected to the output shaft by a series of gears. When the input shaft spins, the gears mesh with each other and send power down the output shaft. The gears in a gear pump can be made out of metal, plastic, or even ceramic.

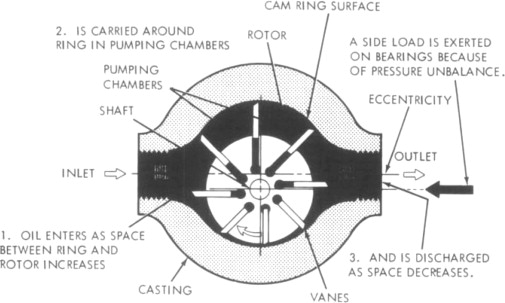

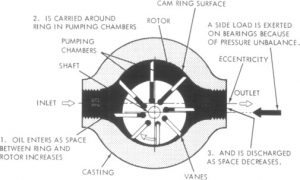

A gear pump works by using the principle of displacement. When the input shaft spins, it causes a displacement in the surrounding fluid. This displacement is what causes the gears to work. The speed at which the input shaft rotates is transferred to the output shaft, and the pump continues to operate.

Advantages of using a hydraulic gear pump

A hydraulic gear pump is a type of engine driven pump used to transfer fluid or compressed air. They are often used in industrial applications, where they are able to move large amounts of liquid or gas with minimal energy input.

One of the main advantages of using a hydraulic gear pump is their ability to operate at high pressures and temperatures. This means that they can be used in applications where other types of pumps would be unsuitable, such as in the oil and gas industry. Additionally, hydraulic gear pumps are relatively quiet, making them an ideal choice for use in noise sensitive areas.

In terms of reliability, hydraulic gear pumps are extremely durable. This is thanks to their design, which includes a number of high quality parts. Additionally, they are typically able to operate in a wide range of conditions, making them well suited for use in a variety of applications.

Another advantage of using a hydraulic gear pump is their reliability. Typically, these pumps are able to handle a wide range of conditions and loads, which makes them a suitable choice for applications where precision is required. Furthermore, these pumps typically have a lifespan that is much longer than other types of engines driven pumps.

Finally, hydraulic gear pumps are relatively easy to operate. This makes them a suitable choice for applications where hands-on expertise is not required.

Disadvantages of using a hydraulic gear pump

There are a few disadvantages to using a hydraulic gear pump. Some of the disadvantages include:

-The gear pump can be difficult to operate and maintain.

-The gear pump can be noisy.

-The gear pump can require specialized equipment, such as a pressure gauge, to operate.

-The gear pump can be expensive.

-The gear pump can be heavy.

-The gear pump can require a lot of space.

-The gear pump can wear out quickly.

Applications of a hydraulic gear pump

A hydraulic gear pump is a type of pump that uses hydraulics to move fluid. It is used in a variety of applications, including oil and gas production, water treatment, and mining. In this article, we’ll look at the applications of a hydraulic gear pump and see how it works.

A hydraulic gear pump is used to move fluid in a variety of applications, including oil and gas production, water treatment, and mining.

In oil and gas production, a hydraulic gear pump is used to move fluids from one location to another. It can be used to transfer oil or gas from the wellhead to storage tanks.

A hydraulic gear pump is also used in water treatment systems. This type of pump is used to move water from one location to another. It can be used to move water from a river or lake into a municipal wastewater treatment plant.

A hydraulic gear pump is also used in mining applications. This type of pump is used to move materials from one location to another. It can be used to move coal from a coal mine into an electric power plant.

Overall, a hydraulic gear pump is a versatile tool that is used in a variety of applications. It is a useful tool for moving fluid in a variety of ways.

Conclusion

A hydraulic gear pump is a type of rotary engine that uses the power of pressurized water to transfer energy from one location to another. This type of pump is often used in industrial settings, such as factories and refineries, because it can be very efficient at transferring large amounts of energy quickly.