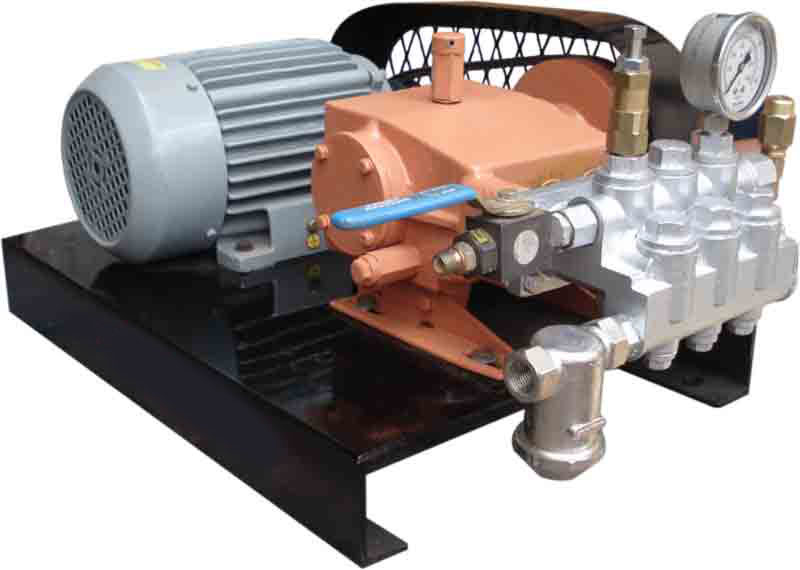

Hydraulic pumps are used in many industries to move fluids and gases. They can operate at high pressure and have a wide range of applications. Pressure is important for these pumps, so it’s important to know how to check it. In this article, we’ll show you how to do the basic checks on a hydraulic pump and how to correct any problems you find.

What is a hydraulic pump?

A hydraulic pump is a device used to move fluid (usually water) using the pressure of the fluid in a reservoir or cylinder. The pressure of the fluid can be converted into mechanical energy to drive a piston or rotor.

The basics of a hydraulic pump

If you have a hydraulic pump and are looking to check the pressure, there are a few basics you need to know. The first is that hydraulic pumps operate on the principle of displacement. This means that energy is transferred from the input (pressurized) fluid to the output (empty) fluid. In order to measure pressure in a hydraulic pump, you need to know the displacement (Pressure = Force x Distance).

There are many ways to measure pressure in a hydraulic pump, but one of the most common is by using a manometer. A manometer is a device that uses mercury as its working fluid and it uses air pressure to control its flow. When you use a manometer to measure pressure in a hydraulic pump, you will need to know the specific gravity (SG) of the mercury. SG is measured in units of 1/1000th of water and it corresponds to how heavy liquid mercury is compared to water. Once you have the SG of the mercury, you can use it along with the pump’s discharge flow rate to calculate pressure in pounds per square inch (PSI).

How does a hydraulic pump work?

A hydraulic pump is a machine that uses fluid pressure to move objects or fluids. The fluid is usually oil or water, but it can also be air or other gases. The main part of a hydraulic pump is the cylinder. The cylinder has a piston in it that moves up and down. This movement makes the fluid inside the cylinder pressurized. When you want to use the hydraulic pump to move an object, you need to first create a pressure difference between the outside world and the inside of the pump. You do this by using a valve. When you close the valve, the pressure difference makes the fluid in the pump pressurized.

Checking pressure in a hydraulic pump

If the hydraulic pump is not working, it is important to check the pressure before replacing any components. The most common way to check the pressure is with a gauge. However, if the gauge is not available, other methods can be used.

The following are some methods for checking pressure in a hydraulic pump.

-Weighted Gauge: This method uses a weight to measure the pressure. To use this method, first connect the gauges to the pump and set the weight so that it balances on top of the gauge. Then turn on the pump and wait until the weight falls off of the gauge. The reading on the gauge will represent the pressure in psi (pounds per square inch).

-Pump Pressure Tester: This device measures the output pressure and provides an output voltage. To use this device, first connect it to a battery and then connect one end of the tester to a hose connection on the pump and connect another end of the tester to a water source. Turn on the pump and wait until you see a voltage reading that corresponds with the pressure in psi (pounds per square inch).

-Manual Gauge: A manual gauge can be used in

Why is it important to know pressure in a hydraulic pump?

If you’re operating a hydraulic pump, it’s important to know the pressure inside the pump so that you can maintain the right level of fluid flow. Pressure is constantly changing in a hydraulic system, so it’s important to monitor it at all times.

There are a few ways to measure pressure in a hydraulic system. The most common way is with a pressure gauge. But sometimes it’s difficult to get a good reading from a pressure gauge because the gauge can be affected by ambient air pressure or other factors in the system.

Another way to measure pressure is with a manometer. A manometer is a sealed device that can be mounted inside or outside of the system. When the system presses against the manometer, the pressure inside the device will change.

It’s important to keep track of pressure in your hydraulic system because it can affect everything from how smoothly your machinery operates to how well your fluids are able to flow. So make sure you have accurate readings from your pressure gauges and manometers, and stay informed about changes in system pressure so you can keep your equipment running smoothly!

How do you check the pressure in a hydraulic pump?

When you are using a hydraulic pump to power something, it is important to make sure the pressure inside the pump is high enough to move the object. There are a few ways to check this.

One way is to use a gauge. A gauge can be mounted on the pump or on the object being moved. When you press the gauge against the object and release it, you should see a movement in the gauge. If the pressure is not high enough, you may need to increase the pressure in the pump.

Another way to check pressure is by using a water displacement method. You will need two containers of different sizes and fill them with water. The smaller container should be placed so that when it is full, the water level reaches the top of the taller container. Now turn on your pump and wait until the water starts moving from the smaller container into the taller one. Once it starts moving, stop pumping and measure how much water has displaced from the smaller container to the taller one. This will give you an estimate of how much pressure is needed in your pump to move objects.

Cautions about checking pressure in a hydraulic pump

When checking the pressure in a hydraulic pump, be sure to use the correct gauge or cylinder. In addition, be sure to use a proper pressure reading method.

Conclusion

If you are working with a hydraulic pump, it is important to know the pressure that the pump is delivering. There are different ways to measure this pressure, but most often it is measured in PSI (pounds per square inch). To check the pressure in your hydraulic pump, you will need to use a gauge.

How do you check pressure in a hydraulic pump,please click topkitparts see more