Hydraulic cylinders are used in a variety of applications, including manufacturing, construction, and agriculture. In order to make them go faster, you need to increase their efficiency. Here’s how you can do that:1. Optimize the design: A well-designed hydraulic cylinder will be more efficient and produce less noise. Make sure to take into account the shape and size of the cylinder, as well as the fluid and pressure inside it.

2. Use high-quality parts: The components inside a hydraulic cylinder need to be of high quality in order to be effective and withstand prolonged use. Look for brands that have a history of producing quality products, and make sure to get replacement parts from these manufacturers if needed.

3. Regularly inspect and clean the cylinder: If the efficiency of your hydraulic cylinder is lowered due to dirt, oil, or other debris build-up, you’ll need to clean it regularly in order to restore its performance. Use a degreaser, solvent, or brush to remove all traces of contamination.

What is a hydraulic cylinder?

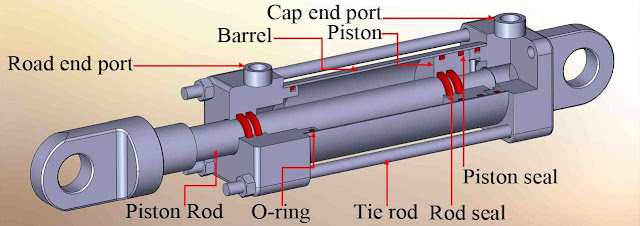

A hydraulic cylinder is a machine used to power various machines. It is made up of a cylinder, piston and cylinder head. The piston is moved up and down by the pressure of the fluid inside the cylinder. This fluid can be either air or oil. The cylinder head provides the necessary connections between the piston and the fluid.

How hydraulic cylinders work

hydraulic cylinders are used in a variety of applications, from car brakes to agricultural machines. Because they use hydraulic fluid, these cylinders can move large amounts of weight quickly. To make the cylinders go faster, there are a few things you can do.

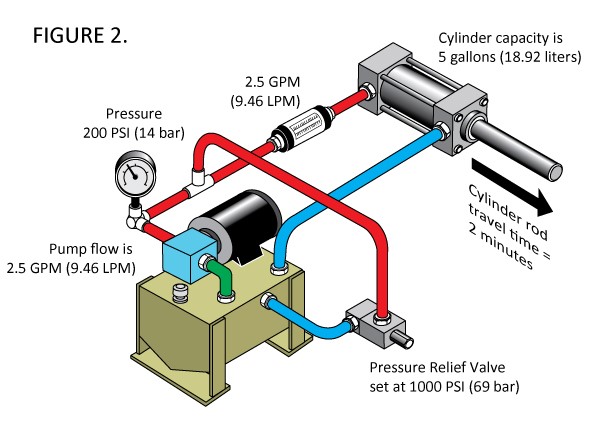

One way to make the cylinders go faster is to increase the pressure inside them. This can be done by either increasing the amount of fluid that’s flowing through the cylinder or by using a higher pressure spring. Another way to make the cylinders go faster is to reduce the amount of friction that they experience. This can be done by using lubricants or by making sure that the surfaces that the cylinder and its moving parts are touching are smooth.

What are the different types of hydraulic cylinders?

There are many different types of hydraulic cylinders, each with its own advantages and disadvantages. The most common types are vertical hydraulic cylinders, horizontal hydraulic cylinders, and rotary hydraulic cylinders. Vertical hydraulic cylinders are the simplest type, and they work by using a fluid (usually water) to push or pull objects up or down. Horizontal hydraulic cylinders use a series of pistons to move objects horizontally. Rotary hydraulic cylinders use a rotating wheel to create motion.

Each type of cylinder has its own advantages and disadvantages. Vertical hydraulic cylinders are the simplest type, and they work by using a fluid (usually water) to push or pull objects up or down. Horizontal hydraulic cylinders use a series of pistons to move objects horizontally. Rotary hydraulic cylinders use a rotating wheel to create motion. Vertical hydraulic cylinders have the advantage of being able to move large objects relatively easily, while horizontal hydraulic cylinders can move smaller objects more quickly. Rotary hydraulic cylinders have the advantage of being able to move complex shapes more easily than either vertical or horizontal cylinder types. However, they can also be more expensive than either vertical or horizontal cylinder types.

How do you use a hydraulic cylinder?

Hydraulic cylinders can be used in a number of ways, but the most common application is in machine tools. When working with a hydraulic cylinder, it is important to understand how it works and how to optimize its performance.

When do you need a hydraulic cylinder?

Hydraulic cylinders are typically used to increase the speed or power of a machine or device. When do you need a hydraulic cylinder? There are a few factors to consider when determining whether or not you need a hydraulic cylinder.

Power: How much power do you need to achieve the desired outcome? For example, if you want to turn a knob on a machine faster, you would need a hydraulic cylinder with more power. Torque: How tight of a turn do you need the knob to make? If you only need a light turn, then a hydraulic cylinder with less torque might be sufficient. Speed: How fast do you want the machine to go? If you only need it to go slightly faster than normal, then a hydraulic cylinder with less power might be sufficient.

When deciding whether or not you need a hydraulic cylinder, it is important to consider the specific needs of your machine or device.

What is the difference between a hydraulic and a pneumatic cylinder?

Hydraulic cylinders are more efficient because they use a pressurized fluid to transmit power. This means the cylinder can move faster and with less force. Pneumatic cylinders rely on air pressure to work, which is why they are usually slower.

Different types of motors for a hydraulic cylinder

There are a few different types of motors you can use for a hydraulic cylinder. The most common is the electric motor, which is typically used for smaller cylinders. Another option is the gas motor, which is used for larger cylinders.

The electric motor is the most common choice because it’s easy to operate and it’s quiet. The drawback of the electric motor is that it doesn’t have as much power as the gas motor. The gas motor is more powerful but it can be difficult to operate because it needs special gas oil and it can be noisy.

Why does a hydraulic cylinder go faster when it is bigger?

When it comes to hydraulic cylinders, there is a certain amount of “pressure” that needs to be exerted in order to move the cylinder’s piston. That pressure is created by the liquid inside of the cylinder and the piston’s weight. The more pressure that is exerted, the faster the piston will move. This is why hydraulic cylinders are often larger on the inside – because they can generate more pressure.

Conclusion

hydraulic cylinders go faster by increasing the displacement of the fluid. This can be done in a number of ways, but the most common way is to increase the pressure of the fluid. By doing this, you are able to push more liquid through the cylinder and make it go faster.

How do you make a hydraulic cylinder go faster,please click topkitparts see more

You article is very very good for how to make faster the hydraulic cylinder. Thanks for sharing my friend.