Hydraulic motors and pumps are essential pieces of equipment in many industrial settings, but understanding how to size them correctly can be tricky. In this article, we’ll explain the basics of sizing a hydraulic motor and pump, including factors to consider when choosing a motor and pump, as well as some common methods for sizing.

Motor size

When sizing a hydraulic motor, the most important factor to consider is the horsepower (hp) rating. A motor with a higher hp rating will be faster and more powerful, while a motor with a lower hp rating will be less powerful. Other factors to consider when sizing a hydraulic motor include the following:

The type of application for which the motor will be used. For example, a pump may be more appropriate for use in agricultural applications than in industrial settings.

The type of fluid being pumped. Hydraulic motors designed for use with liquids (such as water or oil) will generally require more power than those designed for use with gases (such as air).

Pump size

When sizing a pump, the most important factor to consider is the flow rate (in gallons per minute or GPM). The flow rate is determined by multiplying the pump’s rated horsepower by the pump’s impeller speed (in revolutions per minute or rpm). Other factors to consider when sizing a pump include the following:

The type of fluid being pumped. Pumps designed for liquids generally require more power than those designed for gases.

The height of the fluid column being pumped. Pumps that are designed to

What is a hydraulic motor and pump?

A hydraulic motor and pump are used in many applications, such as construction, agriculture, and mining. When a person or machine needs to move a lot of water, a hydraulic motor is used. The pump brings the water up to the required pressure and then sends it down to the desired location.

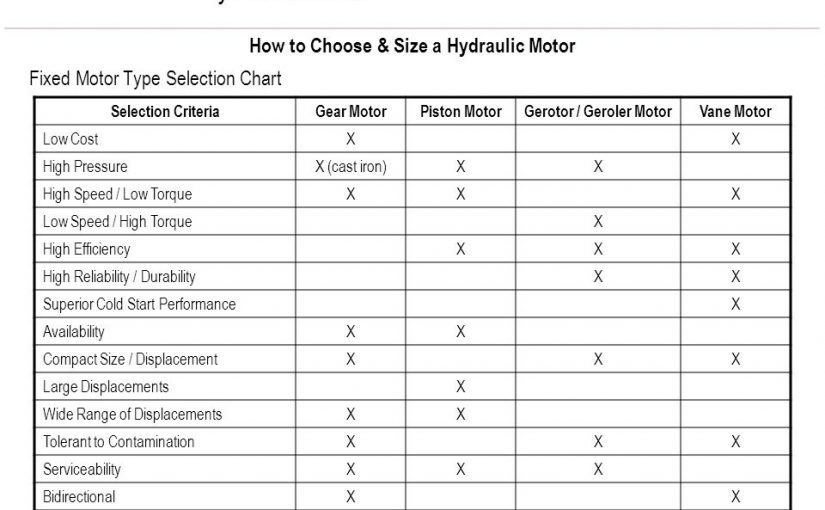

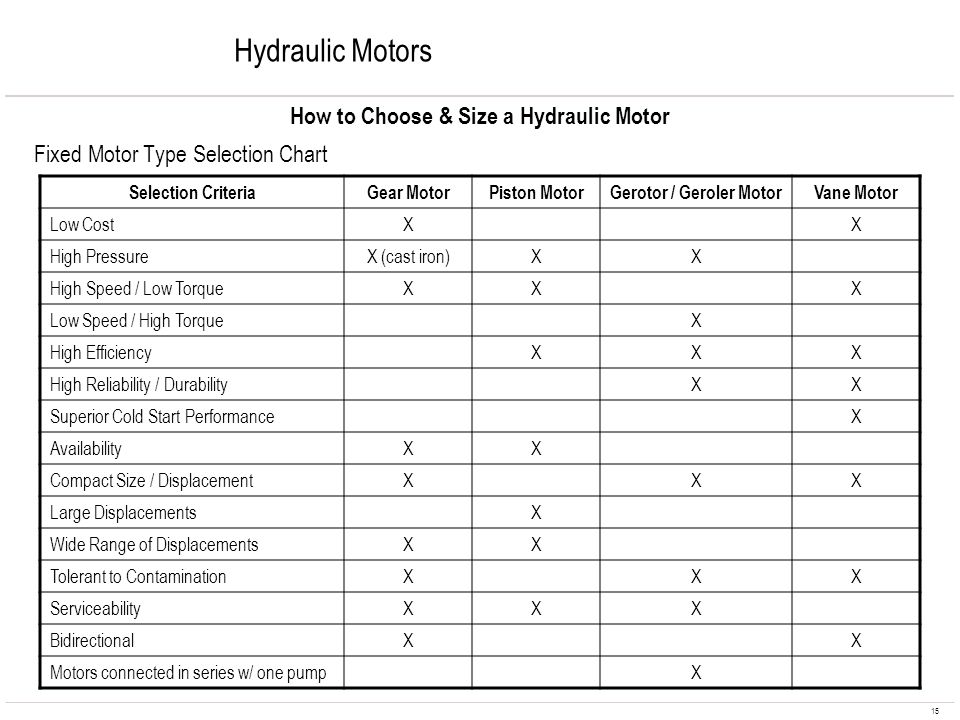

What are the different types of motors and pumps?

There are a few different types of motors and pumps, so it can be hard to know what to choose. Here’s a guide to help you choose the right motor and pump for your project.

First, decide what type of application you need the motor for. Some common applications include manual labor, machine tools, water pumps, and air conditioning units.

Next, look at the size requirements for the motor. Most motors have specific sizes that they’re designed for, so make sure to specify this when ordering.

Finally, consider the type of pump you’re using. There are many different types of pumps available, so make sure to find one that will fit your needs.

How do you size a hydraulic motor and pump?

To size a hydraulic motor and pump, you’ll need to take into account the horsepower (HP) your equipment will require, the number of revolutions per minute (RPM) your equipment will require, and the pressure you need to operate at.

For example, a pump that requires 50 HP and operates at 1000 RPM would need a motor with a horsepower rating of 500 and a rpm rating of 1000.

What factors should you consider when sizing a hydraulic motor and pump?

When sizing a hydraulic motor and pump, you’ll need to take into account a variety of factors such as the application, power requirements, and dimensions. Here are some key considerations:

• Application: The type of application will influence which size motor and pump is appropriate. For example, a motor for a large agricultural machine will require more power than one for a small construction machine.

• Power requirements: The motor’s power requirements will also affect its size. For example, a motor with lower power requirements can be smaller in size than one with higher power requirements.

• Dimensions: The dimensions of the motor and pump also play a role in sizing. For example, a larger motor will require more space on the machine it’s installed on, while a smaller motor may fit on the same machine without issues.

What are the Size Specifications for a Hydraulic Motor and Pump?

When it comes to sizing a hydraulic motor and pump, there are a few things to keep in mind. First, the engine or pump must be able to handle the power requirements of the machine it will be powering. Second, the size of the motor and pump must correspond with the size of the hydraulic system it will be used in. And finally, the dimensions of the system must be compatible with the other components of the machinery.

Here are some general size specifications for a hydraulic motor and pump:

The horsepower requirement for a hydraulic motor can vary depending on the type of application it is being used for, but typically ranges from 150 to 1,000. The size of a pump also varies depending on its horsepower requirement, but typically ranges from 2 to 12 HP. The dimensions of a hydraulic motor and pump also vary depending on their application, but typically fall within a range of 6 inches by 6 inches by 8 inches.

How much horsepower does your pump need?

When sizing a hydraulic motor and pump, you need to consider the horsepower required. This is determined by the type of work that will be done with the pump. The chart below provides an overview of the horsepower requirements for different tasks.

Task Horsepower Required for

Pumping water up a hill 30 Pumping water out of a well 100 Pumping water uphill 140 Pumping water downhill 180

So, if you are pumping water uphill, your pump will require more horsepower than if you are pumping water downhill. Additionally, if you are pumping large volumes of water (such as when cleaning a lake), you will need a higher horsepower pump.

How do You Diameter a Hydraulic Motor and Pump?

Looking to size your hydraulic motor and pump for the job at hand? Here’s a guide on how to do it!

When sizing your hydraulic motor, you first need to determine the horsepower (hp) that the motor will be able to produce. This is typically done by measuring the motor’s RPM. Once you know the hp, you can figure out the pump size needed to handle that power. To do this, divide the hp by the pump size in inches. This will give you the dia/inch (in.) that is required for your pump.

For example, if a motor produces 100 hp and a pump size is required of 18 inches, then the dia/inch (in.) would be 0.375.

Once you have figured out the dia/inch (in.), you can start finding hydraulic motors and pumps that are compatible with your needs. Remember to keep in mind the horsepower and pump size when looking for a specific machine!

Conclusion

If you are in need of a hydraulic motor and pump for your industrial or agricultural applications, then you will want to be familiar with the proper sizing procedure. By following these simple steps, you can ensure that your equipment is correctly fitted and will function as intended.

How do you size a hydraulic motor and pump,please click topkitparts see more