Hydraulic pumps are one of the most common types of pumps used in industrial settings, including construction, mining, and manufacturing. In this article, we’re going to take a closer look at how a 2 speed hydraulic pump works, and see some of the ways that it can be used in various applications.

What is a Hydraulic Pump?

A hydraulic pump is a device that uses pressurized fluid to move objects or materials. It is one of the most common types of engines in use today.

A hydraulic pump works by using a fluid called hydraulics to create a movement. This fluid is pressurized and contained within a tank or container. The pump can then be used to move the object or material by using the pressure to increase the flow of the fluid.

There are many different types of hydraulic pumps, each with its own specific uses. Some common examples include speed hydraulic pumps, pump motors, and water pumps. Each type of pump has its own unique features that make it desirable for certain applications.

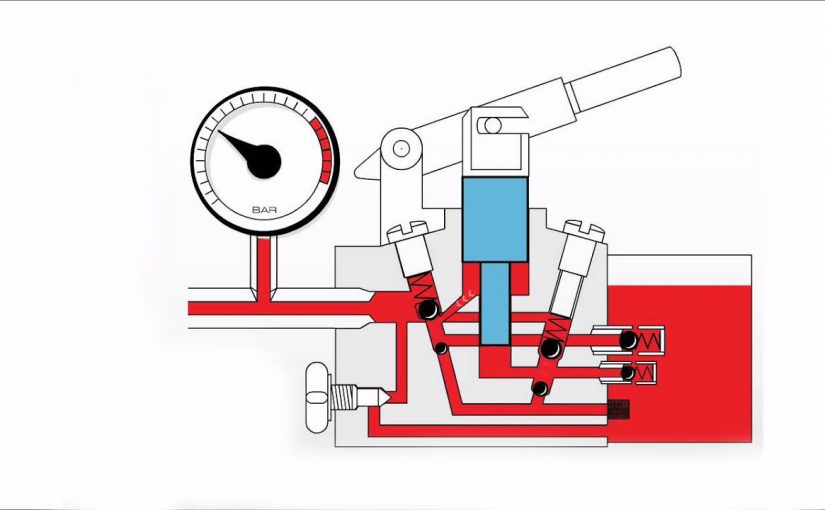

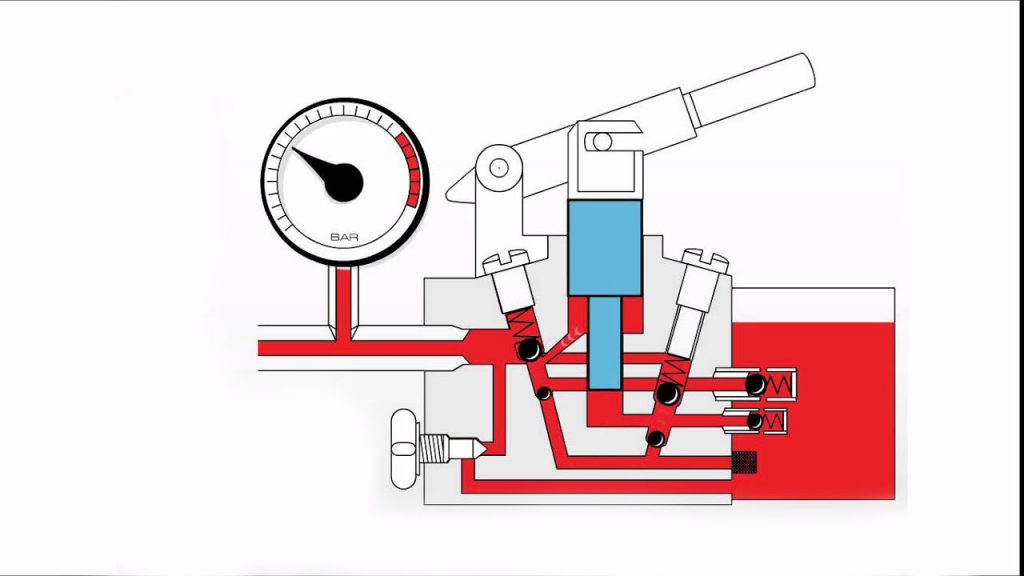

How Does a Hydraulic Pump Work?

A speed hydraulic pump is a type of pump that uses pressure to move fluid. It works by using the pressure of the fluid to move the bits of metal inside it.

The basic principle behind a speed hydraulic pump is simple. When you push water through a pipe, the higher pressure will cause the water to flow faster than the lower pressure. This is what happens with a speed hydraulic pump too. The higher pressure causes the fluid to flow more quickly through the tubes and bearings, which in turn makes it move easier.

What is a 2 speed hydraulic pump?

A speed hydraulic pump is a machine that helps to move liquids, gases and other materials. This type of pump typically has two speeds: low speed and high speed.

The low speed setting is used for slower movements, while the high speed setting is for faster movements. Most speed hydraulic pumps have a bypass valve that allows you to switch between the two speeds.

Speed hydraulic pumps are often used in industries such as manufacturing, mining and construction. They are also used in various applications such as water supply, gas supply, food processing and oil production.

How Does a 2 Speed Hydraulic Pump Work?

A speed hydraulic pump is a type of hydraulic pump that uses two pistons to move the fluid. The pistons move the fluid through the pump by pushing and pulling on the fluid. This allows the pump to move larger quantities of fluid than single-piston pumps.

The speed of a hydraulic pump is controlled by the speed reducer. The speed reducer sends power to one or both pistons, depending on the speed required. This power is then used to move the fluid through the pump.

The speed reducer can also be used to change the direction of the flow of fluid in the pump. This is useful when it is necessary to turn a pump around a corner or when it is necessary to change the direction of the flow of fluid in a pipe.

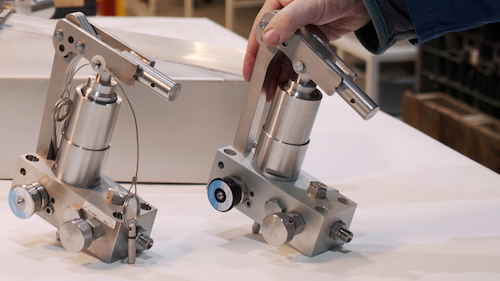

What are the components of a two speed hydraulic pump?

A two speed hydraulic pump is a type of pump that can move fluid at two different speeds. It is made up of four main components: the motor, the drive shaft, the gears, and the Pump.

The motor is what drives the pump and it is generally located inside the pump body. The drive shaft connects the motor to the gears. The gears are what control how fast the pump moves fluid and they are generally located on the outside of the pump. The Pump is what controls how much fluid moves through the system and it is located in between the motor and the gears.

Two speed hydraulic pumps are used in a variety of applications, including manufacturing, agricultural, and construction. They are particularly useful for moving fluids quickly and efficiently.

How to use a 2 speed hydraulic pump

A speed hydraulic pump is a type of pump that can be used to move liquids and gases. This pump is typically used to move fluids in industrial settings, and it is also used in many different applications outside of industrial settings.

This pump works by using an underground liquid reservoir and a moving piston. The piston is connected to the motor, and the motor controls the speed of the piston. This pump can move liquids at two different speeds, and it can also be used to move gas.

This pump is very versatile, and it is often used in multiple applications. It is a common tool for industries such as oil production, food processing, mining, and water treatment.

Where to Find a 2 Speed Hydraulic Pump?

A speed hydraulic pump is a type of pump that can move large amounts of fluid at high speeds. These pumps are used in a variety of industries, including agriculture, mining, and construction.

A speed hydraulic pump works by using two pistons to push and pull the fluid. The pistons are connected by a shaft and a gearbox. The gearbox allows the pistons to move at different speeds, which determines the pumping speed.

Speed hydraulic pumps are often used in applications that require high volumes of fluid to be moved quickly. They are also commonly used in water treatment plants and wastewater treatment facilities.

When should you use a 2 speed hydraulic pump?

Speed hydraulic pumps are often used in industries such as construction, mining, oil and gas production, and agricultural production. They are also used in many industrial applications such as wastewater treatment, water supply and irrigation, and explosive demolition.

A speed hydraulic pump works by moving a fluid at a high speed through a pipe or channel. The pump can be supplied with two different speeds to help you optimize your workflow.

When should you use a 2 speed hydraulic pump?

If you need to move a fluid at two different speeds, a 2 speed hydraulic pump is the perfect tool for you. This type of pump can help you optimize your workflow by moving the fluid at different speeds.

Conclusion

A 2 speed hydraulic pump works by using a rotary motion to move the fluid. This pump is used in many different applications, such as mining and construction.

How does a 2 speed hydraulic pump work,please click topkitparts see more