Hydraulic pumps are used in a variety of applications, from construction sites to oil rigs. In order to operate them, you need a lot of horsepower – and luckily, there are a number of ways to boost that power. Read on to find out how much horsepower you need, and the best ways to get it.

The baseline requirement for a hydraulic pump is around 1,000 horsepower. That may seem like a lot, but in reality it’s not very much when you compare it to other types of machinery. For example, a diesel engine typically has around 3,000 horsepower – so a hydraulic pump requires only a fraction of the power.

In order to get that power, you’ll need to find a source of extra power. There are a number of ways to do this:

1. Use an electric motor.

Electric motors are becoming increasingly popular for powering hydraulic pumps. They’re affordable and easy to install, and they offer plenty of torque – meaning they can easily handle the demands of a hydraulic system.

2. Install an engine conversion kit.

This option is perfect for those who want to beef up their horsepower without having to invest in a new machine. By installing an engine conversion kit, you can easily add more engine power to your vehicle – making it perfect for powering hydraulic systems.

3. Use a gas-powered generator.

If you don’t have access to electricity or don’t want to rely on batteries, then you can use a gas-powered generator to power your hydraulic pump.

What is a hydraulic pump?

A hydraulic pump is a machine that uses pressurized water or oil to move objects or fluids. A typical hydraulic pump has a motor, an impeller, and a reservoir. The motor creates a rotational force that moves the impeller, which in turn generates a pressurized stream of fluid. This stream can move large objects or volumes of fluid quickly and efficiently.

Types of hydraulic pumps

When it comes to hydraulic pumps, there are a few different types to consider. Here’s a quick overview of each:

– reciprocating piston pump: This is the most common type of hydraulic pump, and it uses pistons to move hydraulic fluid. These pumps can handle a lot of power, and they’re usually used for smaller tasks like moving water or oil.

– rotary vane pump: This type of pump uses a rotor to move the fluid, and it’s usually used for larger tasks like pumping water or oil from deep underground. These pumps tend to be more expensive than the reciprocating piston pump, but they’re also able to handle more power.

– diaphragm pumps: This type of pump uses a diaphragm to move the fluid, and it’s usually used for applications that require high pressure (like lifting heavy objects). These pumps tend to be less powerful than the other types of pumps, but they’re also less expensive.

What is the Difference Between Pressure and Force?

hydraulic pump horsepower is measured in forced operate or PSI. PSI is a measure of pressure and it is important to understand the difference between pressure and force when it comes to hydraulic pumps. Pressure is the amount of force that is pushing against something, while force is the amount of energy that is being used to push something. When you are shopping for a hydraulic pump, be sure to look for one that has a high PSI rating. This will ensure that the pump can generate a lot of power and work quickly to move liquids or fluids through systems.

How does hydraulic power make machines run?

In order to understand how hydraulic power works, it is first important to understand how a pump works. A pump converts rotational motion into linear motion by using a series of pistons and cylinders. The basic principle behind hydraulic power is that a high-pressure fluid can move large objects with relatively little energy. This is why machines powered by hydraulic power are often able to move much more weight than machines powered by other forms of energy.

The amount of horsepower needed to run a hydraulic pump depends on the type of pump, the size and speed of the object being moved, and the pressure differential between the fluid being pumped and the atmosphere. For example, a small hand pump can be powered by as little as 0.5 horsepower (0.7 kW), while a large industrial pump can require up to 500 horsepower (730 kW).

How Much Horsepower Do You Need in an Industrial Pump?

In order to run an industrial pump, you will need a certain amount of horsepower. This power is needed to move the hydraulic fluid through the pump and into the machinery it’s intended for. It’s important to choose the right horsepower for your pump, so you don’t overtax it or cause damage. Here are some factors to consider when selecting your horsepower:

– The size of the pump: Bigger pumps require more horsepower to operate than smaller ones.

– The type of machinery: Pumps designed for agricultural use tend to require more power than those used in factories.

– The operating conditions: Extremely cold or hot environments can require more power from a pump than normal.

What factors influence horsepower requirements of the pump?

A pump requires a certain amount of horsepower to operate. Factors that influence the horsepower requirement of a pump include the size of the pump, the type of fluid being pumped, and the pressure being exerted by the fluid.

Why it’s important to know how much horsepower your pump needs

There are a few reasons why knowing the horsepower your pump needs is important.

First, if you’re operating your pump at a higher speed than it was designed for, you may experience wear and tear on the engine and/or pump components. Over time, this can lead to a failed engine or pump – and could even be life-threatening.

Second, if your pump isn’t capable of handling the power required by your application, you may damage other equipment in the vicinity. This could include pipes, valves, or turbines – all of which could result in costly repairs.

Finally, if you don’t know how much horsepower your pump needs to operate safely and efficiently, you may end up spending more money on replacement parts than necessary. So make sure to ask your dealer or supplier for an estimate of your pump’s horsepower requirements – and don’t forget to factor them into your overall budgeting process.

How to calculate the horsepower needed on your pump

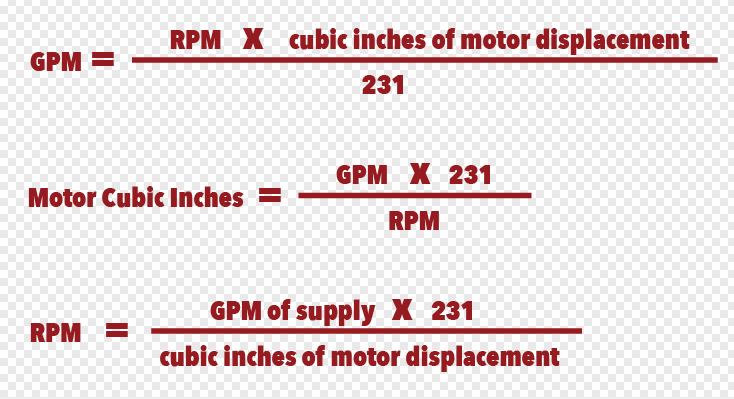

Pump horsepower is a critical factor when selecting a pump to run your hydraulic system. Calculating horsepower is simple, but it can be difficult to estimate the horsepower needed for your application. In this article, we will provide steps for calculating horsepower needs for hydraulic pumps.

To calculate horsepower needs for a hydraulic pump, start by identifying the required working pressure and flow rate. Next, multiply the required working pressure by the desired output speed (in revolutions per minute or rpm). Finally, divide the result by 1000 to obtain the horsepower needed. For example, if you require a pump to operate at a working pressure of 100 psi and a flow rate of 2,000 rpm, your required horsepower would be 2000 hp.

Conclusion

If you need to run a hydraulic pump, you will likely need at least 500 horsepower. More power means faster operation, so it is important to choose the right engine for the job. Use this tool to find out how much horsepower you need to run a particular type of hydraulic pump.

How much horsepower do you need to run a hydraulic pump, please click topkitparts see more