What is a hydraulic pump? A hydraulic pump is a machine used to move fluid using the pressure of pressurized water, oil, or gas. They are used in many applications including mining, waste water treatment and agricultural irrigation.

A hydraulic pump typically requires between 1 and 5 horsepower to operate.

Torque is the rotational force applied to a shaft or drive. In most cases, torque is measured in Newton meters (Nm).

A typical hydraulic pump requires around 1Nm of torque to operate.

Thanks for the question!

What is a hydraulic pump?

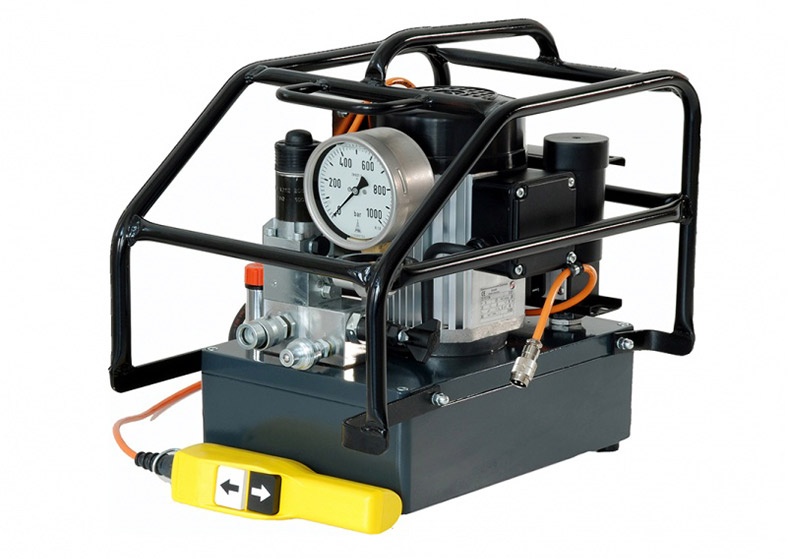

A hydraulic pump is a device that uses the pressure of water or other fluid to move objects or fluids. It is used in a variety of applications, from pumping water from wells to moving oil around pipelines. A hydraulic pump typically consists of two parts: the motor and the pump head. The motor powers the pump head, which pushes the fluid through the system.

How hydraulic pumps work

A hydraulic pump converts the energy of a hydraulic motor into motion. The size and type of pump depends on the application, but all hydraulic pumps need a certain amount of torque to work properly.

Pumps can have a wide range of required torque, depending on the type of pump and the application. In general, pumps need enough torque to move their pistons against the flow of fluid.

The required torque for many common applications is around 1,000 foot-pounds (1,500 Nm). For high-torque applications, such as in mining or construction, requirements can be much higher.

Why is torque important?

Torque is important because it helps to rotate a machine or device. A hydraulic pump needs a lot of torque in order to work properly.

Torque can also be used to turn a screw.

Finally, torque can be used to lift something heavy.

How torque is measured

Torque is a rotational force that causes an object to rotate. Torque is measured in units called Newton meters (Nm). The more torque an object has, the harder it will be to turn it.

A hydraulic pump requires a lot of torque to work. A typical hydraulic pump has a output of 10 Nm or more. This means that the pump can generate a lot of force and turn quickly. To get this level of torque, the pump needs to have a lot of power.

What is the correct torque for a hydraulic pump?

When it comes to installing a new hydraulic pump, you need to make sure that the torque applied is correct. Too much torque can damage the pump, while too little torque can result in reduced performance or even failure.

Here is a list of the maximum torques that should be used for different types of pumps:

-Hydraulic motors: 120-150Nm (89-112 ft.lbs.)

-Piston pumps: 50-65Nm (35-49 ft.lbs.)

-Vibratory pumps: 30-50Nm (22-35 ft.lbs.)

Torque requirements for hydraulic pumps

The torque required for a hydraulic pump is determined by the rpm of the motor and the duty cycle of the pump. The typical duty cycle for a hydraulic pump is 50%.

For example, if a motor is running at 1000 rpm and the duty cycle is 50%, then the pump will require 500 ft-lb (7.5 Nm) of torque to operate.

Guidelines for selecting an appropriate hydraulic pump

When selecting an appropriate hydraulic pump for a particular application, it is important to understand the torque required to operate the pump. This information can be found in the pump’s specifications or in a manufacturer’s operating manual. In general, hydraulic pumps require between 1 and 5 torques to operate (depending on the type of pump). However, this range may be slightly different depending on the type of pump and the application. For example, an electric motor typically requires less torque than a diesel engine to operate. Therefore, electric pumps are often used in applications that do not require a lot of power (such as lifting objects). Conversely, a diesel engine typically requires more torque to operate than an electric motor. This is because a diesel engine has more internal combustion engines that can work together to produce more power. Consequently, diesel pumps are often used in applications that require a lot of power (such as moving heavy objects).

Determining the amount of torque that needs to be applied to a hydraulic pump for specific applications.

When it comes to hydraulic pumps, torque is one of the most important factors to consider. Torque is the rotational force that is applied to a rotating component, and is measured in foot-pounds (ft-lbf). In order to properly operate a hydraulic pump, it requires a certain amount of torque.

There are a few factors that affect the required torque for a specific application, including: rpm of the rotating component, the type of hydraulic fluid being used, and the size and weight of the pump.

To determine how much torque is needed for a given application, it’s important to understand these factors. Fortunately, there are several tools that can be used to calculate the required torque.

One such tool is the mechanical horsepower calculator. This calculator uses data from the rpm of the rotating component and the type of hydraulic fluid being used to calculate the required torque. Other calculators can be used to calculate the required torque based on other factors, such as size and weight of the pump.

Once it’s determined how much torque is needed, it’s easy to find an appropriate engine or motor for use with a hydraulic pump. By choosing an engine that meets

Conclusion

In this article, we will be discussing the torque that a hydraulic pump needs in order to function correctly. This information is important for those who are working with these pumps regularly, as well as for those who are planning on using them in the future. By understanding the torque requirements of a hydraulic pump, you can ensure that your equipment is functioning at its best and that any repairs or replacements will be done properly.

How much torque does a hydraulic pump need,please click topkitparts see more