Hydraulic pumps are used in a variety of industries to move fluids, and they rely on a certain amount of torque to do their job. In this article, we’ll explore how much torque a hydraulic pump needs and how you can determine it. By the end, you’ll know just enough about hydraulic pumps to confidently choose the right one for your project!

Before we dive in, it’s important to understand the basics of torque. Torque is a measure of the force that is required to rotate an object around a fixed axis. In hydraulic pumps, torque is used to move fluids through systems.

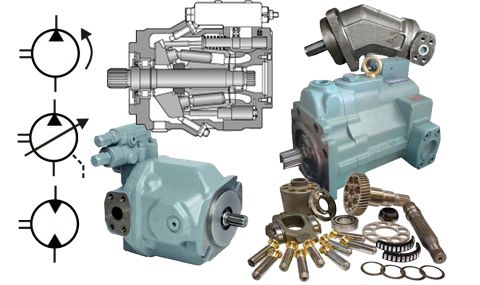

There are numerous factors that affect how much torque a hydraulic pump needs. Some of these factors include the size and type of pump, the fluid being pumped, and the application. However, one of the most important factors is the speed at which the pump is rotating.

When you’re shopping for a hydraulic pump, it’s important to determine your application’s necessary speed and torque requirements. You can do this by consulting with an expert or by using specific testing equipment.

Now that you know what torque a hydraulic pump needs, let’s take a closer look at how you can calculate it!

How to Calculate Torque for a Hydraulic Pump

To calculate torque for a hydraulic pump, you first need to know the rotational speed of the pump. Second, you need to know the weight of the object being rotated. Finally, you need to know the force required to rotate that object. Here’s how it works:

1) Rotational Speed: To

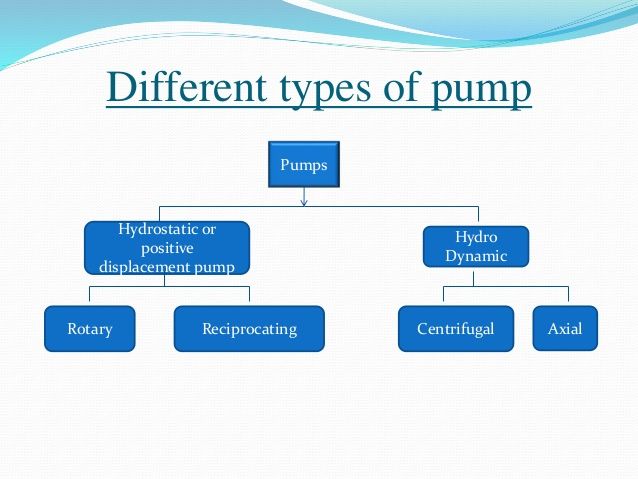

What is a hydraulic pump?

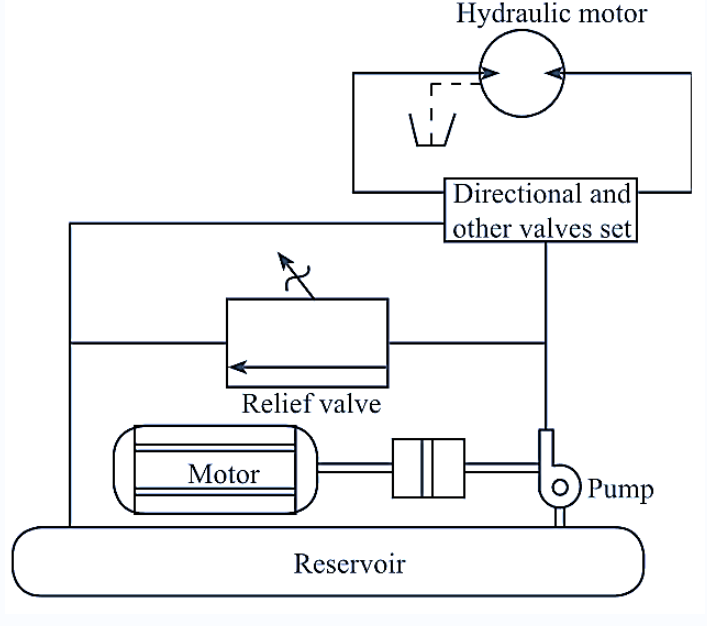

A hydraulic pump is a machine that uses hydraulics to move fluid. This fluid can be anything from water to oil. A hydraulic pump works by using the pressure of the fluid to move the object it is connected to.

Hydraulic pumps are used in a variety of different applications, including manufacturing, transportation, and farming. They are also used in many home appliances, such as washers and dryers.

How does a hydraulic pump work?

A hydraulic pump is a device that uses pressurized fluid to move objects. It is used in many industries, such as construction, mining, and farming. A hydraulic pump works by using the power of hydraulics to push and pull objects. The amount of torque required to operate a hydraulic pump depends on the type of pump and the application.

Hydraulic pumps use pressurized fluid to move objects. They work by using the power of hydraulics to push and pull objects. The amount of torque required to operate a hydraulic pump depends on the type of pump and the application.

What is torque?

Torque is a measure of rotational force. It is defined as the product of the momentary angular velocity and the length of the arm or shaft through which it is applied. Torque can be applied in various ways, such as using a wrench to turn a bolt, using a ratchet to tighten a screw, or using a hydraulic pump to move fluid.

Torque is important because it can be used to rotate objects, and can be used to pull or push other objects. It is also important in engineering because it is a measure of the rotational force that can be applied to a shaft or arm to achieve certain goals, such as moving a machine or lifting a weight.

Torque specifications

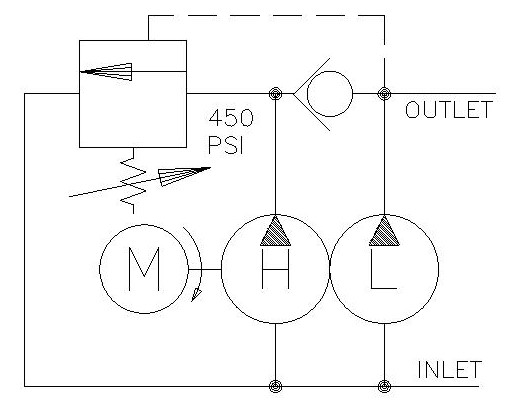

A hydraulic pump requires relatively low torque to operate. Many manual pumps typically require 1-2 foot-pounds (1-2 Nm) of torque. Electric and automatic pumps require even less torque, usually ranging from 0.5-1 foot-pounds (0.5-1 Nm).

Pumps that require high torque often have larger motors, allowing them to generate more power. These pumps are often used in industrial applications where higher volumes of fluid are required.

Does a pump need a certain amount of torque?

A hydraulic pump needs a certain amount of torque to work correctly. This is typically in the range of 10 to 12 foot-pounds, although it can vary depending on the type of pump and the specific application.

What is the difference between a hydraulic pump and a mechanical pump?

A hydraulic pump is powered by hydraulic fluid, while a mechanical pump relies on mechanical energy to operate. Hydraulic pumps are typically more efficient and have longer life spans than mechanical pumps.

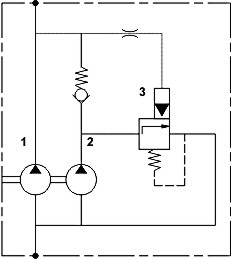

Calculating the torque needed for a particular pump

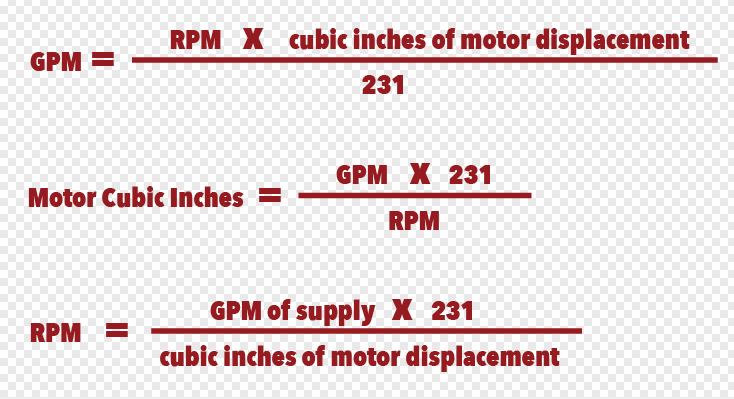

A hydraulic pump can require a certain amount of torque to operate effectively. To calculate this torque, you need to know the pump’s RPM and the volume of water it is moving. You can use these values to calculate the required Torque (in inch-pounds) using the following formula:

Torque (inch-pounds) = RPM x Volume (gallons per minute)

For example, if a pump is running at 1000 RPM and is moving 2000 gallons of water per minute, the required torque would be 2000 x 2 = 4000 inch-pounds.

What are the different torque ratings on pumps?

Pumps typically require torque in the range of 100-500 ft-lb. Torque ratings are based on the applications for which the pump will be used and the operating parameters of the pump.

Some common torque ratings for pumps include:

100 ft-lb for garden hoses

200 ft-lb for deck hoses

300 ft-lb for well pumps

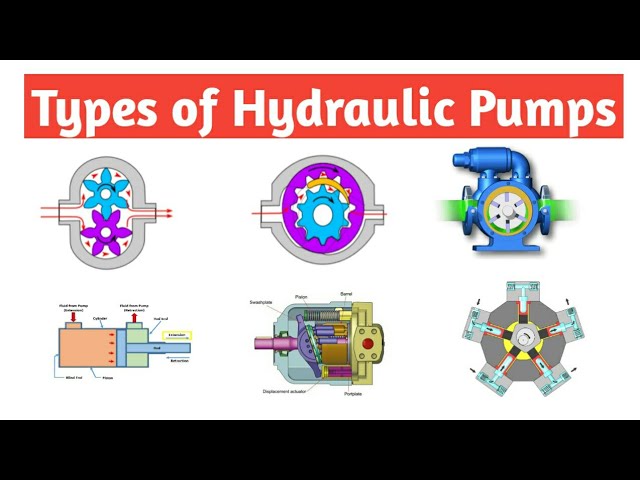

Analyzing the torque requirement for various pumps

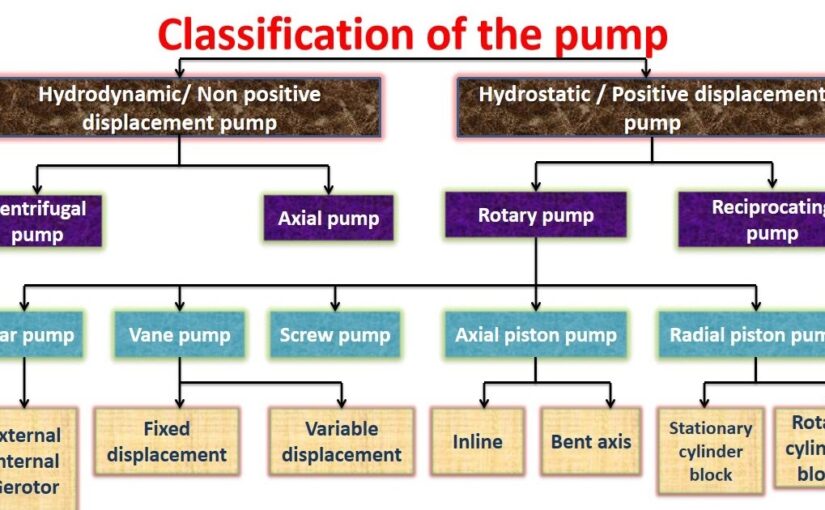

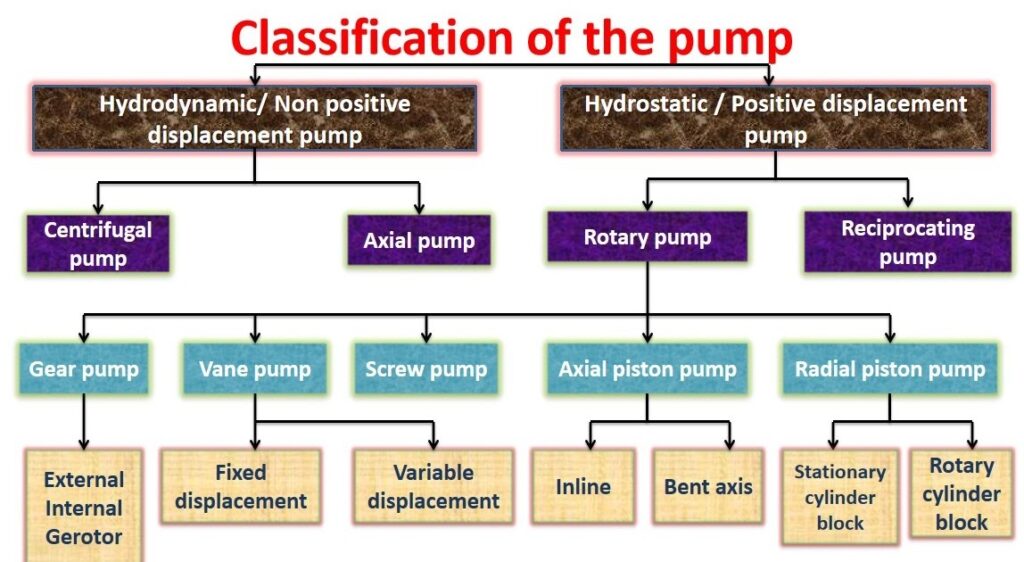

A hydraulic pump needs a certain amount of torque to function properly. This is especially the case for larger pumps, which require more power to move larger objects. In this article, we’ll look at the torque required for different types of hydraulic pumps, and figure out how much power they need to function effectively.

Pump Type Torque Requirement

centrifugal pump 1,500 to 3,000 ft-lbs

reciprocating pump 2,000 to 12,000 ft-lbs

piston pump 500 to 5,000 ft-lbs

How much torque a hydraulic pump needs

Hydraulic pumps need a lot of torque to function properly. The more torque the pump has, the faster it can move fluid and the more power it can generate. In most cases, you need at least 3,000 ft-lb (4,500 Nm) of torque to start and operate a hydraulic pump.

Some pumps require even more torque to function properly. For example, some high-flow pumps require 6,000 ft-lb (8,700 Nm) of torque to start and operate.

Conclusion

In this article, we will be discussing the torque requirements of a hydraulic pump. Torque is a measure of the force that is required to rotate an object. A hydraulic pump requires a certain amount of torque to function properly, and if the torque requirements are not met, the pump can fail catastrophically. It is important to understand the torque requirements of your intended application in order to buy the right hydraulic pump.

How much torque does a hydraulic pump need, please click topkitparts see more