hydraulic pumps are essential devices in any hydraulic system, and there are many different types available on the market. In this article, we will be taking a look at the different types of hydraulic pumps and ranking them according to their effectiveness and practicality.

1. Single-stage hydraulic pumps

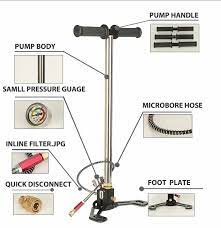

Single-stage hydraulic pumps are the most common type of pump and are typically used in smaller applications. They work by extracting a small amount of fluid from a reservoir and then pumping it through a pipeline or other device. Single-stage pumps are relatively simple and can be operated using standard hand tools, making them ideal for use in small businesses and home repairs.

2. Two-stage hydraulic pumps

Two-stage hydraulic pumps are slightly more complex than single-stage pumps, but they offer significantly greater performance. Two-stage pumps work by extracting a larger amount of fluid from a reservoir and then pumping it through a pipeline or other device. This allows them to move larger volumes of fluid at faster speeds, making them ideal for applications such as water supply systems and industrial production facilities.

3. Three-stage hydraulic pumps

Three-stage hydraulic pumps are the most powerful type of pump available and are typically used in large applications such as water supply systems and industrial production facilities. They work by extracting a large amount of fluid from a reservoir and then pumping it through a pipeline or other device three times. This allows them to move enormous volumes of fluid at extremely fast speeds, making them

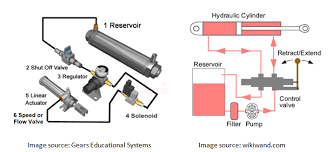

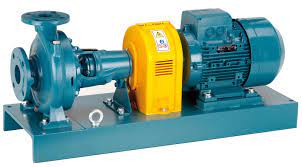

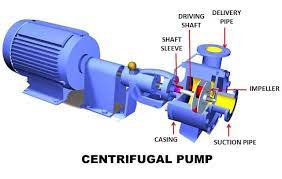

What is a hydraulic pump?

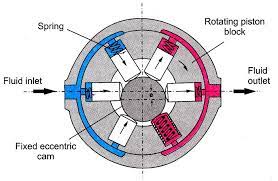

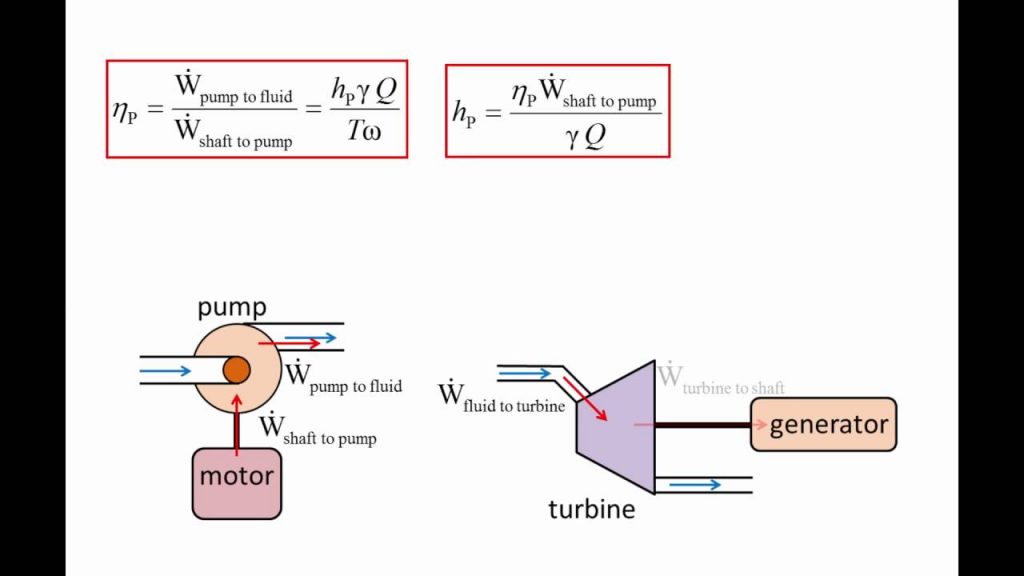

A hydraulic pump is a device that uses the energy of pressurized liquid or gas to move objects. They are commonly used in industrial and agricultural settings, to move things like water, oil, and grain. There are many different types of hydraulic pumps, but the most common is the piston pump.

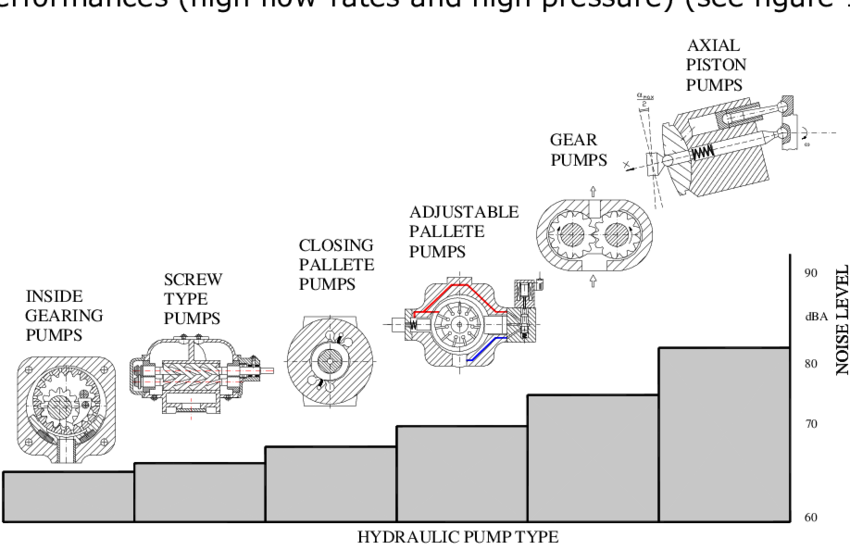

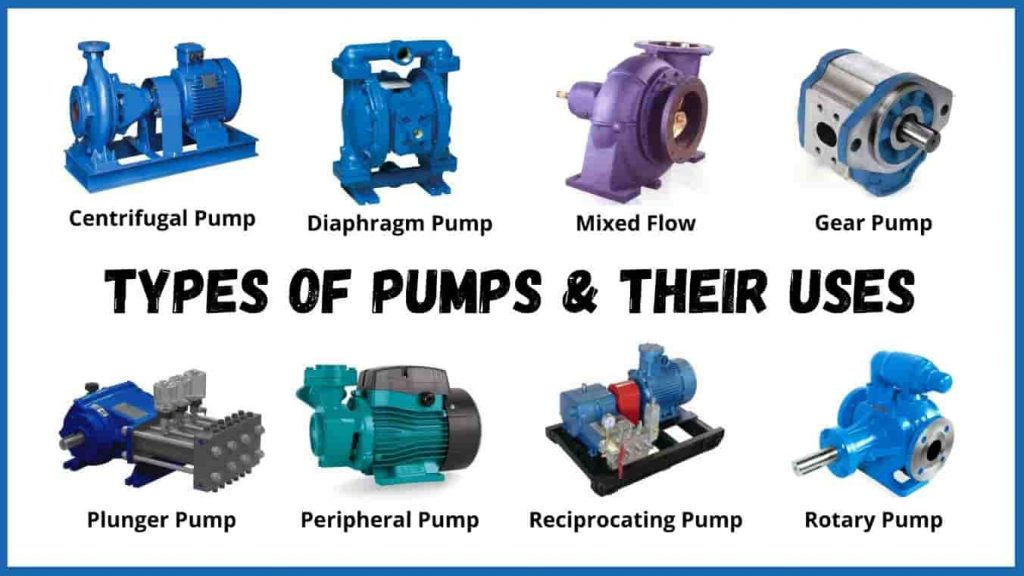

Types of hydraulic pumps

There are a few different types of hydraulic pumps out there, and it can be hard to decide which one is the best for your needs. In this post, we’ll go over the different types of hydraulic pumps and what they have to offer. We’ll also give you a few tips on how to choose the right one for your project.

Why to use a hydraulic pump?

There are many reasons why you might want to use a hydraulic pump. Pumps can be used for a variety of purposes, such as moving fluid, lifting heavy objects, and more. When considering which pump to use, it important to consider the specific needs of your project. There are many different types of hydraulic pumps available on the market, so it’s important to find one that will meet your specific needs. Here are some reasons why you might want to consider using a hydraulic pump:

1. Fluid movement – A hydraulic pump can move large amounts of fluid quickly and easily. This is great for tasks like water purification or oil drilling.

2. Heavy lifting – A hydraulic pump can help you lift heavy objects easily. This is useful for tasks like moving construction materials or loading trucks with cargo.

3. Speed and efficiency – Hydraulic pumps are incredibly efficient and quick at completing tasks. This means they can save you time and energy overall.

When deciding which hydraulic pump to use for your project, it’s important to consider the specific needs of the task at hand. There are many different types of pumps available on the market, so finding the right one for your project is easy

What are the benefits of each type of pump?

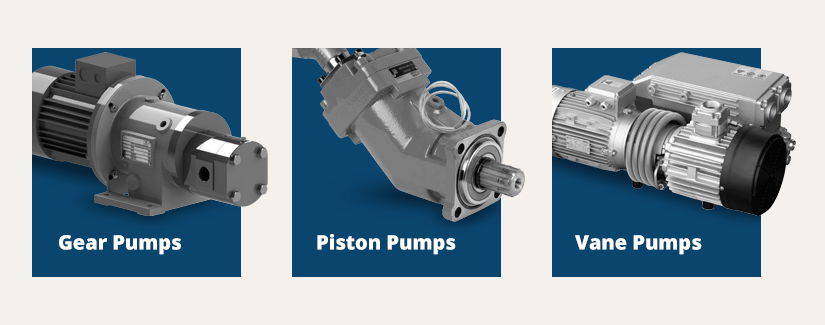

There are many types of hydraulic pumps on the market, each with its own set of benefits. Here is a brief overview of each type:

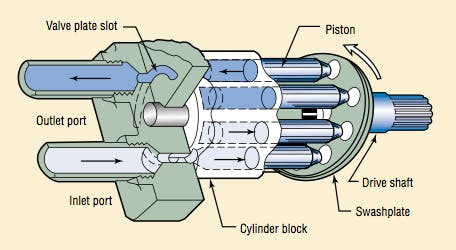

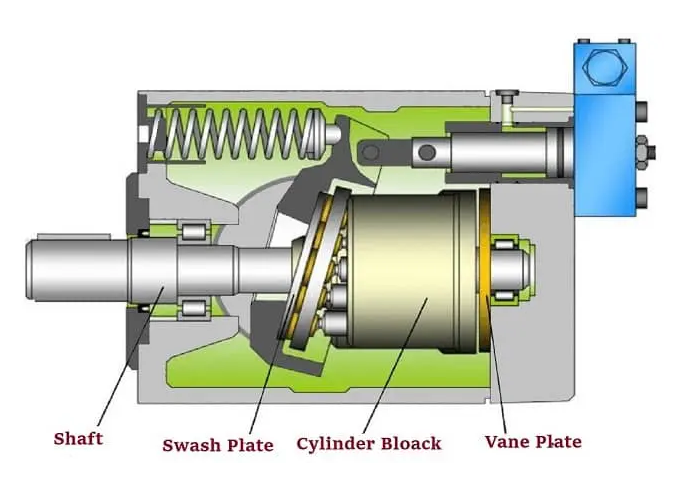

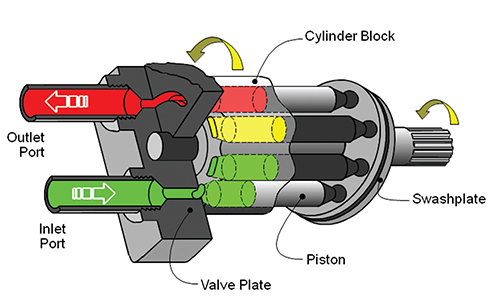

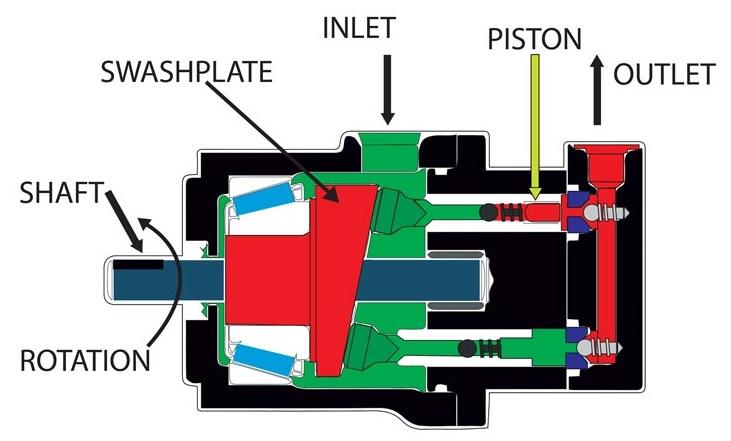

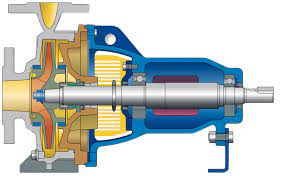

piston pump – These pumps use pistons to move the fluid, and are the most common type. They’re affordable and easy to operate, making them a good choice for small businesses. However, they don’t have the ability to move large volumes of fluid quickly, so they’re not ideal for large projects.

vane pump – These pumps use vanes to move the fluid, and are more powerful than piston pumps. They’re also more expensive than piston pumps, but they can handle larger volumes of fluid quickly.

diaphragm pump – These pumps use diaphragms to move the fluid, and are unique because they have the ability to switch between horizontal and vertical flow. This makes them perfect for applications that need both high speed and high volume flow capabilities.

How much does a hydraulic pump cost?

A hydraulic pump can cost anywhere from a few hundred dollars to several thousand dollars. The price depends on the make and model of the pump, the size and type of tank it needs to operate from, and any accessories or upgrades needed.

What are the best hydraulic pumps for different applications?

There are many different types of hydraulic pumps, each with its own specific advantages and disadvantages. The best pump for a particular application will depend on the specific needs of that application. Here are four common types of hydraulic pumps and their respective applications: rotary piston pumps, screw pumps, diaphragm tanks, and vane pumps.

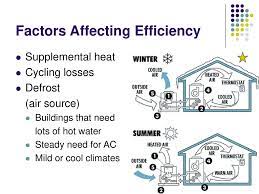

Rotary piston pumps are generally used in applications where high pressure and flow rates are required, such as in oilfield drilling and water treatment. They are also commonly used in industrial automation applications. Screw pumps are ideal for applications where low pressure and flow rates are required, such as in home water heating or milk production. Diaphragm tanks are most commonly used in agricultural applications, where they can pump large volumes of fluid at high pressures. Vane pumps are usually used in air conditioning or refrigeration applications.

Comparison of the best hydraulic pumps

Hydraulic pumps are the lifeblood of many industries, from construction to agricultural. But which is the best? This article compares five of the best hydraulic pumps on the market.

1. Volvo Penta D4H Pumps

The Volvo Penta D4H pumps are considered some of the best in the industry. They are strong and reliable, and can handle a lot of pressure. They are also very affordable, making them a great option for those on a budget.

2. Flowtech HM-274G Hydrostatic Pumps

Flowtech HM-274G hydrostatic pumps are another great option for those looking for quality and affordability. They are reliable and can handle a lot of pressure, making them great for applications such as irrigation.

3. Schaeffler Group HC-1202D Hydrostatic Pumps

Schaeffler Group HC-1202D hydrostatic pumps are another high-quality option. They are reliable and efficient, and can handle a lot of pressure. They also have a long lifespan, meaning they will last for years without needing to be replaced.

4. Kirloskar Hydro Pumps Limited HS-25B/HS-25

Conclusion

There are many different types of hydraulic pumps on the market, and it can be hard to decide which one is right for your specific needs. That’s why I have put together this buyers guide to help you choose the best one for your project. In addition to reviewing various features and specs, I also included a buyer’s guide to choosing the right type of hydraulic pump for your specific application. Hopefully, this will help you find the perfect pump for your next project!

Which is the best hydraulic pump. please click topkitparts see more