Hydraulic systems are used in a variety of industries for various applications. These systems use pressurized fluids to power machinery and equipment, and their effectiveness relies on their design and configuration. A two-pump hydraulic system, in particular, offers several advantages over other hydraulic setups.Advantages of using a 2 pump hydraulic setup The primary advantage of a two-pump hydraulic system is increased efficiency. In a typical hydraulic system, a single pump is used to power all the components. However, a two-pump setup uses one pump to power the high-pressure components and another pump to power the low-pressure components. This allows for better control and more efficient use of the hydraulic fluid.

A two-pump hydraulic system also offers increased flexibility. By separating the high-pressure and low-pressure components, the system can be configured to meet specific requirements. For example, a two-pump system can be designed to power high-pressure components like cylinders and motors while also powering low-pressure components like filters and coolers.

Another advantage of a two-pump hydraulic system is increased reliability. In a typical single-pump hydraulic system, a failure of the pump can result in the entire system being shut down. However, in a two-pump system, if one pump fails, the other pump can continue to power the system. This means that the downtime associated with maintenance and repairs is significantly reduced.

Factors to consider when designing a two-pump system Designing a two-pump hydraulic system requires careful consideration of several factors. These factors include the system’s pressure and flow rate requirements, the components’ compatibility, and the system’s overall design and configuration.

Pressure and flow rate requirements: The pressure and flow rate requirements of a hydraulic system are determined by the components being powered. It is important to ensure that the pumps selected can provide the required pressure and flow rate for the system to function properly.

Component compatibility: The hydraulic fluid used in the system must be compatible with all the components. Incompatible fluids can cause damage to the components and lead to system failure.

System design and configuration: The design and configuration of the system can impact its performance and efficiency. The placement and orientation of components, piping and hose routing, and valve selection and placement all need to be carefully considered.

Comparison with other hydraulic setups A two-pump hydraulic system offers several advantages over other hydraulic setups, including single-pump and three-pump systems.

Single-pump systems are the most basic hydraulic setups and use a single pump to power all the components. While single-pump systems are simple, they offer less control and flexibility than a two-pump system. In addition, if the pump fails, the entire system shuts down.

Three-pump systems use three pumps to power high-pressure, medium-pressure, and low-pressure components. While three-pump systems offer greater control and flexibility than single-pump systems, they are more complex and costly. A two-pump system can provide similar performance and efficiency without the added complexity and cost of a three-pump system.

In summary, designing a two-pump hydraulic system requires careful consideration of several factors, including pressure and flow rate requirements, component compatibility, and system design and configuration. A two-pump system offers several advantages over other hydraulic setups, including increased efficiency, flexibility, and reliability.

Determining System Requirements and Hydraulic Component Selection

Before designing a hydraulic system, it is important to determine the system’s requirements and select the appropriate hydraulic components. This process involves considering the pressure and flow rate requirements, hydraulic fluid selection and compatibility, and selecting the appropriate pumps, motors, reservoirs, and filters.

Hydraulic fluid selection and compatibility considerations The hydraulic fluid is a critical component of the hydraulic system, as it transmits power and lubricates the system’s components. The selection of the appropriate hydraulic fluid is crucial to ensure that the system operates efficiently and reliably.

When selecting a hydraulic fluid, it is essential to consider its compatibility with the system’s components. Different hydraulic components may have different material requirements, and the hydraulic fluid must be compatible with all of them. Incompatible fluids can cause damage to the components and lead to system failure.

In addition to compatibility, the hydraulic fluid’s viscosity, temperature range, and anti-wear properties must also be considered. The fluid’s viscosity affects the system’s flow rate, while its temperature range determines whether the system can operate in different environments. The fluid’s anti-wear properties are crucial to ensure that the system’s components remain lubricated and free from damage.

Pressure and flow rate requirements The pressure and flow rate requirements of a hydraulic system are determined by the components being powered. For example, a hydraulic cylinder requires a specific pressure and flow rate to operate correctly.

To ensure that the system meets the pressure and flow rate requirements, it is important to select the appropriate pumps and motors. The pumps and motors must be capable of providing the required pressure and flow rate for the system to function correctly.

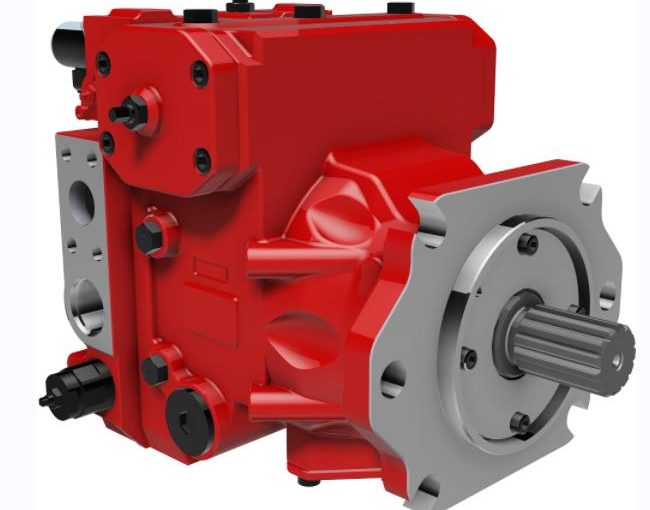

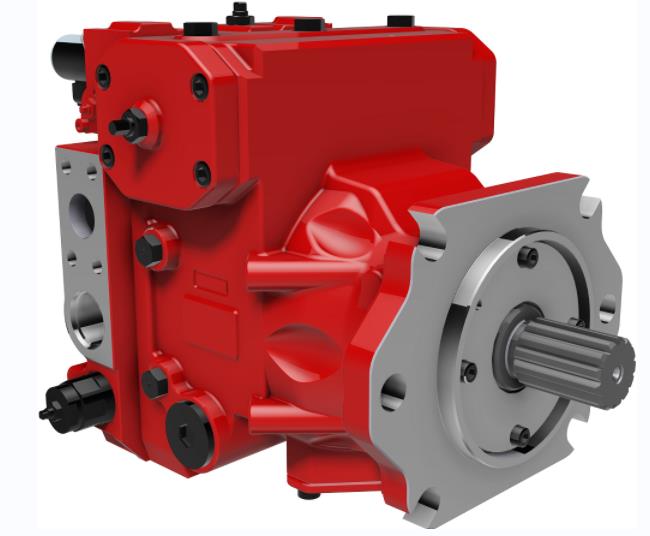

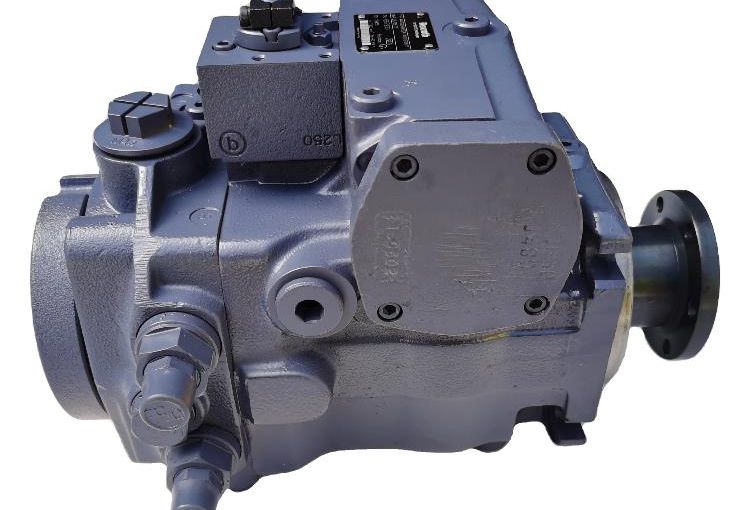

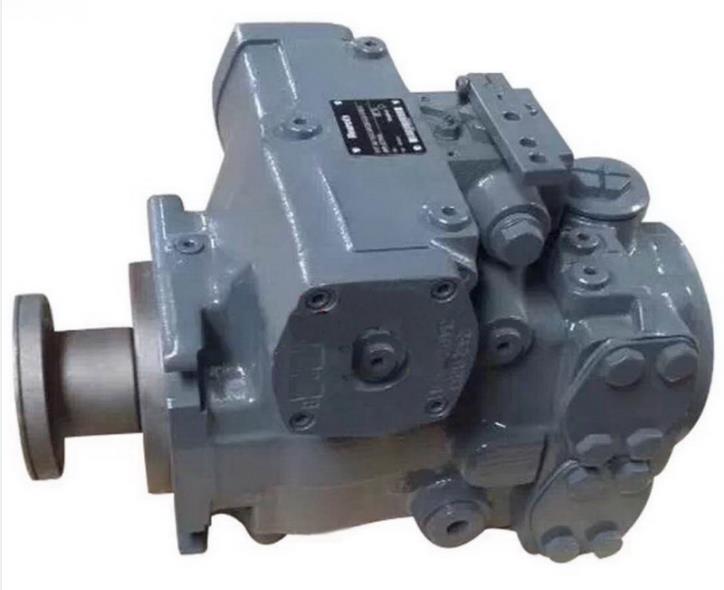

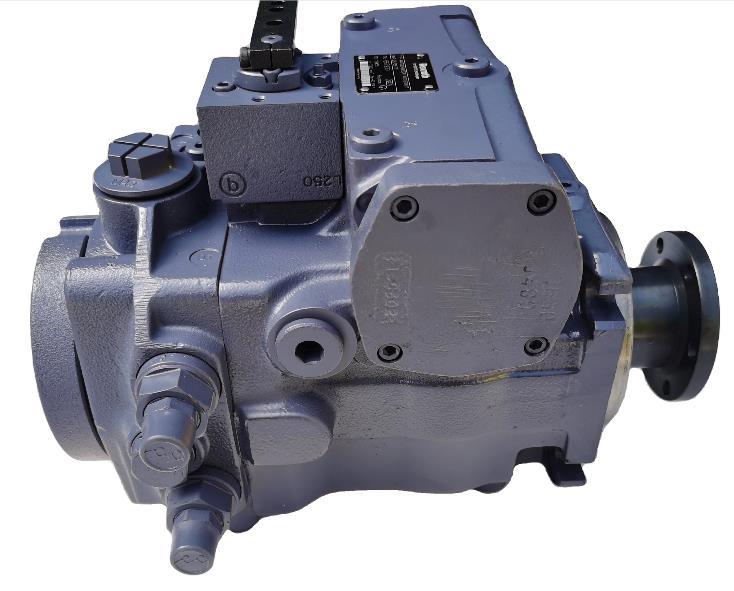

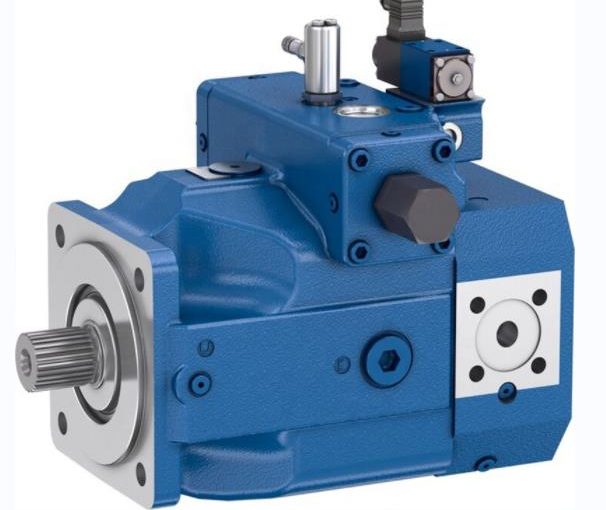

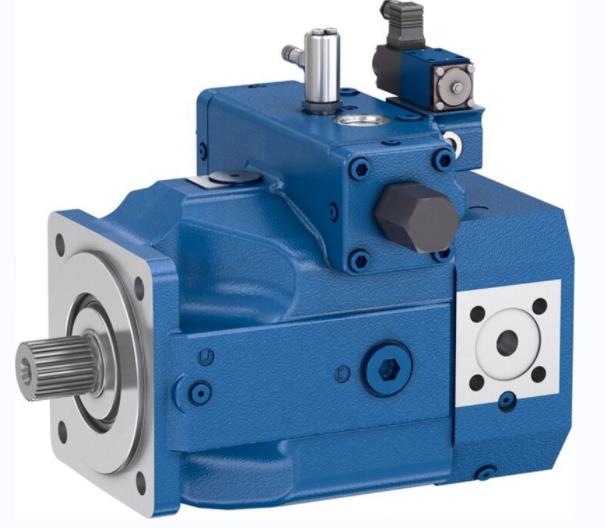

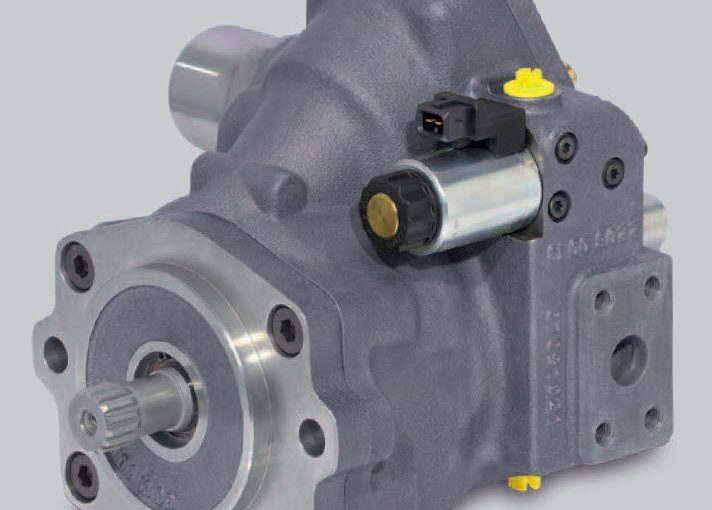

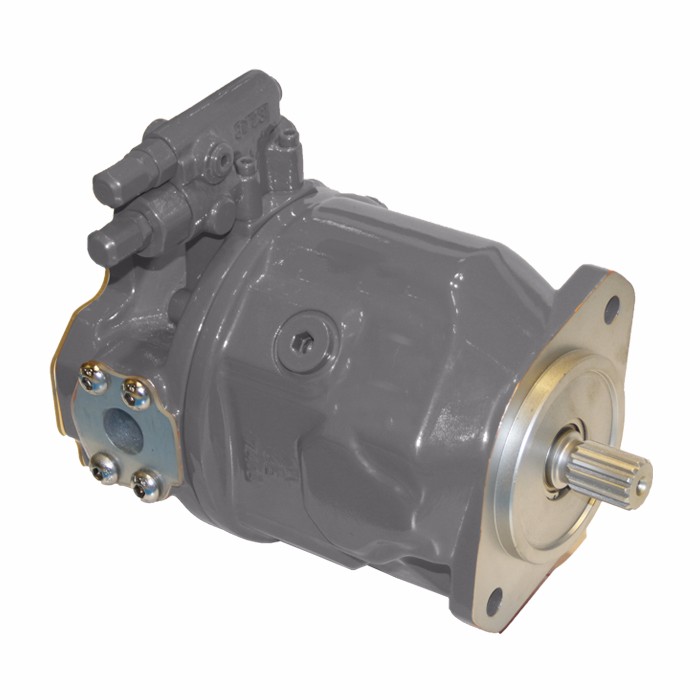

Pump and motor selection based on system requirements When selecting pumps and motors for a hydraulic system, it is essential to consider the system’s pressure and flow rate requirements. The pumps and motors must be capable of providing the required pressure and flow rate for the system to function correctly.

Other factors to consider when selecting pumps and motors include the system’s efficiency, noise level, and maintenance requirements. High-efficiency pumps and motors can reduce the system’s energy consumption and operating costs. Low-noise pumps and motors can improve working conditions and reduce noise pollution. Pumps and motors with low maintenance requirements can reduce downtime associated with maintenance and repairs.

Reservoir and filter considerations The hydraulic fluid reservoir and filter are also critical components of the hydraulic system. The reservoir stores the hydraulic fluid, while the filter removes contaminants and ensures that the fluid remains clean.

When selecting a reservoir, it is essential to consider its size, shape, and material. The reservoir must be large enough to hold the required amount of hydraulic fluid, and its shape must allow for easy filling and draining. The material of the reservoir must be compatible with the hydraulic fluid and resistant to corrosion.

When selecting a filter, it is essential to consider its filtration efficiency and capacity. The filter must be capable of removing contaminants from the hydraulic fluid to ensure that the system operates efficiently and reliably. The filter’s capacity must be sufficient to handle the system’s flow rate.

In summary, determining the system requirements and selecting the appropriate hydraulic components is crucial to ensure that the hydraulic system operates efficiently and reliably. The selection of the hydraulic fluid, pumps, motors, reservoirs, and filters must be based on the system’s pressure and flow rate requirements, compatibility, efficiency, noise level, and maintenance requirements.

System Design and Configuration

The design and configuration of a hydraulic system play a crucial role in its performance and efficiency. The system must be designed to meet the pressure and flow rate requirements while minimizing energy consumption and reducing operating costs. This section will discuss the various design options for a two-pump hydraulic system, the placement and orientation of components, piping and hose routing considerations, and valve selection and placement.

Design options for a two-pump hydraulic system A two-pump hydraulic system offers greater flexibility than other hydraulic setups, allowing for specific requirements to be met. Two common design options for a two-pump hydraulic system include a split-flow design and a priority-flow design.

In a split-flow design, the high-pressure pump powers the high-pressure components, while the low-pressure pump powers the low-pressure components. This design ensures that the high-pressure components receive sufficient flow rate and pressure without wasting energy on low-pressure components.

In a priority-flow design, the high-pressure pump powers both the high-pressure and low-pressure components. However, the low-pressure components only receive the required flow rate to operate, and the excess flow rate is directed towards the high-pressure components.

Placement and orientation of components The placement and orientation of hydraulic components are crucial to ensure that the system operates efficiently and reliably. The components must be arranged in a way that minimizes pressure drops, reduces energy consumption, and allows for easy maintenance.

The high-pressure components should be located as close to the pump as possible to minimize pressure drops and reduce energy consumption. The low-pressure components can be located further away from the pump, as they require less pressure and flow rate.

The orientation of components must also be considered. For example, a hydraulic cylinder must be positioned vertically to ensure that the piston remains lubricated and does not wear unevenly.

Piping and hose routing considerations Piping and hose routing must be carefully considered to ensure that the system operates efficiently and reliably. The routing must minimize pressure drops and ensure that the hydraulic fluid flows in the correct direction.

The piping and hose diameter must also be selected based on the pressure and flow rate requirements. The diameter must be sufficient to handle the required flow rate without causing excessive pressure drops.

Valve selection and placement The selection and placement of valves are essential to ensure that the system operates efficiently and reliably. The valves must be selected based on their function and compatibility with the hydraulic fluid and components.

For example, pressure relief valves are used to protect the system from overpressure and must be placed in the correct location to function correctly. Directional control valves are used to control the flow direction and must be selected based on the system’s pressure and flow rate requirements.

In summary, the design and configuration of a two-pump hydraulic system must be carefully considered to ensure that the system operates efficiently and reliably. The design options for a two-pump system include split-flow and priority-flow designs, while the placement and orientation of components, piping and hose routing, and valve selection and placement must be carefully considered to minimize pressure drops, reduce energy consumption, and ensure that the system operates efficiently and reliably.

Installation and Maintenance Best Practices

Proper installation and maintenance procedures are critical to ensure that a hydraulic system operates efficiently and reliably. This section will discuss the proper installation procedures, start-up and shutdown procedures, maintenance requirements and schedules, and troubleshooting and fault diagnosis techniques.

Proper installation procedures The installation of a hydraulic system requires careful consideration to ensure that it operates efficiently and reliably. The installation procedures must be followed correctly to ensure that the system is safe and functional.

The installation should be performed by trained personnel and should include the following steps:

- Mounting and aligning the hydraulic components

- Connecting the piping and hoses

- Filling the system with hydraulic fluid

- Bleeding the air from the system

- Testing the system for leaks and proper operation

Start-up and shutdown procedures Proper start-up and shutdown procedures are essential to ensure that the hydraulic system operates efficiently and reliably. The following steps should be followed:

- Before starting the system, ensure that all components are correctly installed and connected.

- Slowly start the pump and monitor the pressure and flow rate to ensure that they are within the system’s requirements.

- After the system has been started, check for leaks and monitor the system’s operation.

- When shutting down the system, slowly reduce the pump speed to allow the hydraulic fluid to cool and prevent damage to the system’s components.

Maintenance requirements and schedules Regular maintenance is essential to ensure that the hydraulic system operates efficiently and reliably. The following maintenance requirements and schedules should be followed:

- Regularly check the hydraulic fluid level and condition.

- Replace the hydraulic fluid at regular intervals to ensure that it remains clean and free from contaminants.

- Clean the hydraulic components regularly to prevent the accumulation of dirt and debris.

- Inspect the system’s components for wear and damage and replace any damaged components immediately.

- Perform regular system tests to ensure that the pressure and flow rate remain within the system’s requirements.

Troubleshooting and fault diagnosis techniques Even with proper maintenance and installation procedures, hydraulic systems may experience problems. Troubleshooting and fault diagnosis techniques are essential to identify and fix these problems quickly.

Some common problems with hydraulic systems include leaks, inadequate pressure, and excessive noise. Troubleshooting and fault diagnosis techniques include:

- Using a pressure gauge to monitor the system’s pressure and flow rate

- Inspecting the system’s components for wear and damage

- Checking the hydraulic fluid level and condition

- Inspecting the piping and hoses for leaks or damage

In summary, proper installation and maintenance procedures are critical to ensure that a hydraulic system operates efficiently and reliably. The installation procedures should be followed correctly, and the system should be regularly maintained to prevent wear and damage. Start-up and shutdown procedures should be followed, and troubleshooting and fault diagnosis techniques should be used to identify and fix problems quickly.

Applications and Industries That Benefit from Two-Pump Hydraulic Systems

Two-pump hydraulic systems are widely used in various industries and applications due to their flexibility, efficiency, and reliability. This section will discuss some of the industries that commonly use two-pump systems, specific applications that benefit from a two-pump setup, and the advantages of a two-pump hydraulic system in various industries.

Examples of industries that commonly use two-pump systems Two-pump hydraulic systems are used in various industries, including:

- Manufacturing: Two-pump systems are used to power production lines, machine tools, and other equipment used in the manufacturing process.

- Construction: Two-pump systems are used to power construction equipment like cranes, excavators, and bulldozers.

- Agriculture: Two-pump systems are used in agricultural machinery like tractors and combines.

- Mining: Two-pump systems are used to power mining equipment like loaders, excavators, and haul trucks.

Specific applications that benefit from a two-pump setup Two-pump hydraulic systems offer greater flexibility than other hydraulic setups, allowing for specific requirements to be met. Some applications that benefit from a two-pump setup include:

- Mobile equipment: Mobile equipment like cranes, excavators, and bulldozers require a flexible hydraulic system that can power high-pressure and low-pressure components simultaneously.

- Presses: Hydraulic presses require a high-pressure system to apply force, as well as a low-pressure system to retract the press.

- Injection molding machines: Injection molding machines require a high-pressure system to inject the plastic into the mold, as well as a low-pressure system to open and close the mold.

Advantages of a two-pump hydraulic system in various industries Two-pump hydraulic systems offer several advantages over other hydraulic setups, making them a popular choice for various industries. Some advantages of a two-pump hydraulic system include:

- Increased efficiency: Two-pump systems allow for better control and more efficient use of the hydraulic fluid, reducing energy consumption and operating costs.

- Increased flexibility: Two-pump systems offer increased flexibility by separating the high-pressure and low-pressure components, allowing for specific requirements to be met.

- Increased reliability: Two-pump systems offer increased reliability by allowing the system to continue operating if one pump fails.

- Increased safety: Two-pump systems can be configured to include redundant safety features, reducing the risk of accidents and injuries.

In summary, two-pump hydraulic systems are widely used in various industries and applications due to their flexibility, efficiency, and reliability. Industries like manufacturing, construction, agriculture, and mining commonly use two-pump systems, and applications like mobile equipment, presses, and injection molding machines benefit from a two-pump setup. The advantages of a two-pump hydraulic system in various industries include increased efficiency, flexibility, reliability, and safety.

Safety Considerations for Two-Pump Hydraulic Systems

Hydraulic systems can be hazardous if not installed, operated, and maintained correctly. Proper safety measures and precautions must be taken during installation and operation to ensure that the system is safe for personnel and equipment. This section will discuss the potential hazards associated with hydraulic systems, safety measures and precautions during installation and operation, and the importance of regular maintenance and inspection for safety purposes.

Potential hazards associated with hydraulic systems Hydraulic systems can be hazardous due to the high pressures and forces involved. Some potential hazards associated with hydraulic systems include:

- High-pressure fluid injection injuries: Hydraulic fluid injected into the skin can cause serious injuries, including tissue damage, amputation, or death.

- Pinch point injuries: Hydraulic components like cylinders and valves can crush or pinch fingers or other body parts.

- Fire and explosion hazards: Hydraulic fluid is flammable and can ignite under certain conditions, causing a fire or explosion.

- Noise hazards: Hydraulic systems can produce high levels of noise, which can damage hearing and cause other health problems.

Safety measures and precautions during installation and operation Proper safety measures and precautions must be taken during the installation and operation of hydraulic systems to ensure that they are safe for personnel and equipment. The following safety measures and precautions should be taken:

- Use trained personnel for installation and operation.

- Use proper personal protective equipment (PPE) for personnel, including eye and hand protection.

- Follow proper installation procedures to ensure that the system is safe and functional.

- Use safety guards and barriers to prevent personnel from coming into contact with hydraulic components.

- Ensure that the hydraulic fluid is compatible with the system’s components and that the system is free from leaks.

- Follow proper start-up and shutdown procedures to prevent damage to the system’s components.

- Regularly inspect the system for wear and damage and replace any damaged components immediately.

Importance of regular maintenance and inspection for safety purposes Regular maintenance and inspection are essential to ensure that hydraulic systems are safe for personnel and equipment. The following maintenance and inspection procedures should be followed:

- Regularly inspect the system for leaks, wear, and damage and replace any damaged components immediately.

- Replace the hydraulic fluid at regular intervals to ensure that it remains clean and free from contaminants.

- Regularly clean the system’s components to prevent the accumulation of dirt and debris.

- Perform regular system tests to ensure that the pressure and flow rate remain within the system’s requirements.

- Regularly inspect safety guards and barriers to ensure that they are in good condition and functioning correctly.

In summary, hydraulic systems can be hazardous if not installed, operated, and maintained correctly. Potential hazards associated with hydraulic systems include high-pressure fluid injection injuries, pinch point injuries, fire and explosion hazards, and noise hazards. Proper safety measures and precautions, including using trained personnel, using proper PPE, following proper installation procedures, using safety guards and barriers, and regular maintenance and inspection, must be taken to ensure that hydraulic systems are safe for personnel and equipment.

Cost Considerations for Two-Pump Hydraulic Systems

The cost of a hydraulic system can vary depending on several factors, including the type of system, the components used, and the operating and maintenance costs. This section will discuss the initial cost and investment considerations, operating and maintenance costs, and comparison with other hydraulic setups in terms of cost-effectiveness.

Initial cost and investment considerations The initial cost of a hydraulic system includes the cost of the components, installation, and commissioning. Two-pump hydraulic systems are more expensive than other hydraulic setups due to the additional components and complexity of the system.

However, two-pump systems offer greater flexibility and efficiency than other hydraulic setups, which can result in long-term cost savings. The initial investment in a two-pump system can be justified by the reduced energy consumption and increased efficiency over the system’s lifetime.

Operating and maintenance costs The operating and maintenance costs of a hydraulic system include the cost of hydraulic fluid, energy consumption, and maintenance and repair costs. Two-pump hydraulic systems can be more energy-efficient than other hydraulic setups due to the ability to separate the high-pressure and low-pressure components and only use the required flow rate and pressure for each component.

The maintenance and repair costs of a hydraulic system can vary depending on the quality of the components and the frequency and quality of maintenance. Two-pump systems may require more maintenance due to the additional components and complexity, but proper maintenance can extend the system’s lifetime and reduce repair costs.

Comparison with other hydraulic setups in terms of cost-effectiveness Two-pump hydraulic systems offer greater flexibility and efficiency than other hydraulic setups, but they can be more expensive initially. However, the long-term cost savings of a two-pump system can justify the initial investment, especially in applications where efficiency and flexibility are essential.

Other hydraulic setups like single-pump systems and variable displacement pump systems may be less expensive initially but may not offer the same flexibility and efficiency as a two-pump system. The operating and maintenance costs of these systems may be higher in the long run due to their reduced efficiency.

In summary, the cost of a hydraulic system can vary depending on several factors, including the type of system, the components used, and the operating and maintenance costs. Two-pump hydraulic systems are more expensive initially but offer greater flexibility and efficiency than other hydraulic setups, which can result in long-term cost savings. The operating and maintenance costs of a hydraulic system can be reduced by proper maintenance and use of energy-efficient components.

Future Developments and Advancements in Two-Pump Hydraulic Systems

Hydraulic systems continue to evolve, driven by the need for increased efficiency, reliability, and safety. Two-pump hydraulic systems are no exception, with recent innovations and advancements focusing on improving their performance and capabilities. This section will discuss recent innovations and advancements in two-pump systems, potential future developments in the field, and the impact on industries and applications that use hydraulic systems.

Recent innovations and advancements in two-pump systems Recent innovations and advancements in two-pump hydraulic systems include:

- Variable-speed pumps: Variable-speed pumps can adjust their flow rate and pressure to match the system’s requirements, reducing energy consumption and improving efficiency.

- Smart sensors and controls: Smart sensors and controls can monitor the system’s performance, detect faults and anomalies, and adjust the system’s operation to optimize performance and reliability.

- Regenerative systems: Regenerative systems can recover energy from the system’s high-pressure flow and reuse it to power low-pressure components, improving efficiency and reducing energy consumption.

Potential future developments in the field Potential future developments in two-pump hydraulic systems include:

- Increased automation: Automation can improve the system’s performance, reliability, and safety by reducing the need for human intervention and improving the system’s responsiveness.

- Integrated power management: Integrated power management systems can optimize the system’s power usage and efficiency, reducing energy consumption and operating costs.

- Improved materials and components: Improved materials and components, including advanced composites and 3D printing, can improve the system’s performance, reliability, and durability while reducing weight and cost.

Impact on industries and applications that use hydraulic systems The impact of future developments and advancements in two-pump hydraulic systems on industries and applications that use hydraulic systems can be significant. Improved efficiency and reliability can reduce operating costs, improve productivity, and increase safety. Automation and integrated power management can reduce the need for personnel and improve the system’s responsiveness, making it more suitable for remote or hazardous applications.

Improved materials and components can reduce weight and cost while improving the system’s performance and durability, making it more suitable for applications where weight and space are critical. The impact of future developments and advancements in two-pump hydraulic systems on industries and applications that use hydraulic systems can result in improved competitiveness, reduced environmental impact, and improved safety and reliability.

In summary, hydraulic systems continue to evolve, driven by the need for increased efficiency, reliability, and safety. Recent innovations and advancements in two-pump hydraulic systems focus on improving their performance and capabilities, including variable-speed pumps, smart sensors and controls, and regenerative systems. Potential future developments in the field include increased automation, integrated power management, and improved materials and components. The impact of these developments and advancements on industries and applications that use hydraulic systems can be significant, resulting in improved competitiveness, reduced environmental impact, and improved safety and reliability.