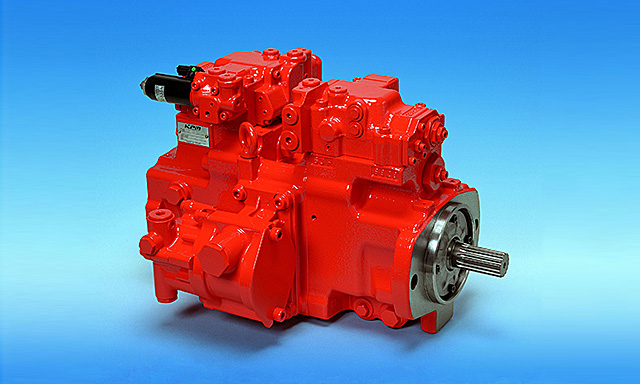

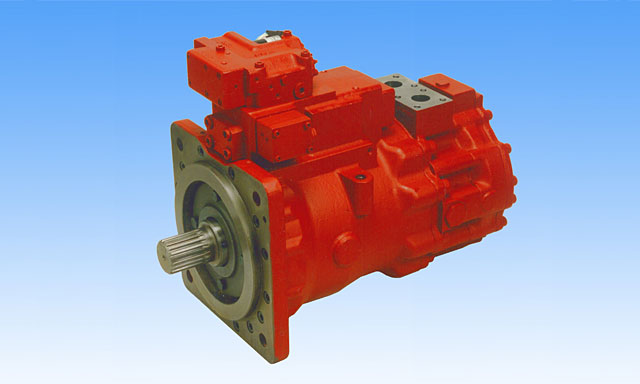

The Kawasaki K7VG Hydraulic Pump is a high quality, water-cooled, two stage pump with a maximum pressure of 2,000 PSI. This unit is designed for use with high pressure hydraulic systems, including most agricultural equipment and industrial machinery.

The Kawasaki K7VG Hydraulic Pump has been designed for rugged use in industrial applications where durability and reliability are critical. The K7VG can be used in many applications including farm equipment, construction equipment, mining machines and more.

The Kawasaki K7VG hydraulic pump is one of the most trusted models of variable displacement pumps.

The Kawasaki K7VG hydraulic pump is one of the most trusted models of variable displacement pumps. It is a high-pressure pump that can be used for a variety of applications, from hydraulic power steering and braking systems to hydraulic elevators and more.

The Kawasaki K7VG has been in production since 2002. It is designed to provide smooth power delivery for all types of hydraulic applications. It comes with a range of features that make it ideal for both commercial and industrial uses.

The Kawasaki K7VG is an oil-lubricated pump that operates on high-pressure fluid up to 7,000 psi (475 bar). It features an open volute design that allows it to handle high fluid pressures while maintaining low levels of noise and vibration. The pump also features an oil filter system that protects its internal components from contaminants and keeps them clean while they are being used. The filter can be cleaned or replaced as needed without having to stop or even shut down your operation while doing so.

The Kawasaki K7VG is a variable displacement piston pump featuring a swash plate type cam mechanism to control oil flow.

The Kawasaki K7VG is a variable displacement piston pump featuring a swash plate type cam mechanism to control oil flow. The K7VG is designed for use in hydraulic systems requiring high-pressure, low-flow applications. These pumps feature an integral gear pump and an integral swash plate mechanism. They can be used for a wide variety of applications including hydraulic power steering systems, transmission lubrication, power brakes and more.

The K7VG piston pump has been designed to meet the requirements of the automotive market. It features a smooth running diaphragm type valve that can maintain constant pressure at low speeds and high pressure at high speeds. The pump has been designed with special attention paid to vibration resistance and durability under extreme conditions, making it ideal for use in heavy duty service applications such as agricultural machinery, construction equipment and many other industrial applications where long life expectancy is required.

Because of its design and construction, the Kawasaki K7VG hydraulic pump is able to provide stable discharge pressure even at low speeds.

The Kawasaki K7VG is a high-speed, high-pressure hydraulic pump used in the mining industry. Because of its design and construction, the Kawasaki K7VG hydraulic pump is able to provide stable discharge pressure even at low speeds. This makes it an ideal choice for mobile equipment that needs to operate at variable speeds.

The Kawasaki K7VG features an integral shaft seal and a high-pressure relief valve that automatically opens if pressure exceeds 140 bar (2000 psi). It also has a high-pressure relief valve that automatically opens if pressure exceeds 140 bar (2000 psi). The pump’s compact size allows it to fit easily into tight spaces without sacrificing power or performance.

This can be especially significant in the operation of heavy machinery.

The Kawasaki K7VG is a high-pressure centrifugal pump that is designed to deliver large volumes of oil at high pressure. The pump can be used in applications such as construction and mining equipment, mobile equipment, marine vessels and other heavy machinery.

The Kawasaki K7VG has a number of features that make it ideal for these types of applications. For example, its internal components are made from durable materials that can withstand exposure to harsh conditions. This includes an extra thick impeller shaft made from hardened steel which provides superior strength and durability compared to other pumps in its class. The shaft also contains anti-corrosion coatings which prevent rust and corrosion from forming inside the pump when exposed to moisture or other contaminants such as salt water or dirt.

The Kawasaki K7VG hydraulic pump is built for dependable performance in a variety of applications.

The Kawasaki K7VG hydraulic pump is built for dependable performance in a variety of applications. It features a heavy-duty design for long-lasting durability and dependability. The unit has an oil capacity of 3.2 ounces, 1/2 NPT male discharge port, and a maximum flow rate of 10 gpm at 3000 psi. It has a maximum operating pressure of 3000 psi and temperature rating of 300°F (149°C). It comes with an ANSI Class 150 seal as standard equipment. This unit can be mounted on any flat surface or attached to an enclosure with the included mounting bracket kit.

The Kawasaki K7VG comes in seven different styles, each offering different flow rates, pressures and shaft configurations.

The Kawasaki K7VG is a high-pressure hydraulic pump that is used to move oil through your system. This pump has a 3/4″ NPT port on the side of the housing and can be mounted to either an engine or transmission. The Kawasaki K7VG is available in seven different styles (K7VGF, K7VGJ, K7VGM, K7VGN, K7VGQ, K7VGR and K7VGS). Each style offers different flow rates and pressure capabilities so make sure that you order the correct size for your application.

Several different models are available with metal or plastic connectors, as well as several models with a radial seal shaft design.

Kawasaki’s K7VG series of hydraulic pumps are designed for use in a variety of industrial applications, including power steering and other hydraulic systems. These pumps are available in several different sizes, which are designated by the number of pistons used to drive the output shafts. For example, a three-piston pump means that it has three pistons moving back and forth in order to create pressure at the output end of the piston rod. This type of pump is often referred to as a double-acting piston pump because both sides of each piston are used to generate pressure at once.

Kawasaki K7VG Pump direct mounting design makes it easy to install and maintain.

Its direct mounting design makes it easy to install and maintain. Kawasaki’s unique S-shaped pump body provides smooth operation and durability. The compact design allows for a compact installation space. In addition, the high-pressure oil passage is arranged on the right side of the pump body to ensure that no oil will leak out even if there are any defects in the sealing surface or gasket due to aging or corrosion.

The Kawasaki K7VG hydraulic pump is designed with special features including a pre-lubrication function which prevents damage due to dry running conditions when starting up, and a built-in pressure relief valve which prevents abnormal pressure buildups in case of an emergency stop or loss of lubrication.

Overall, the Kawasaki K7VG-HW is a great pump and an excellent value. The inclusion of the NPT adapter makes it easy to get the job done right with minimal setup or expense. And if you’re looking for something a bit tougher than some of the other units on the market, this one might fit the bill.