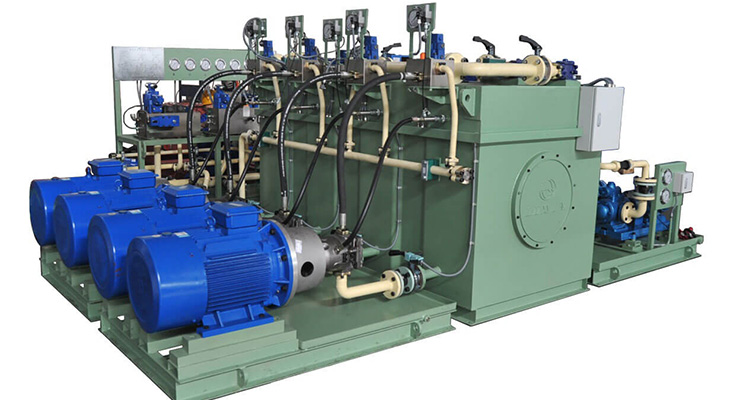

Hydraulic gear pump is an important machine used in various industrial processes such as mining, construction, metallurgy and chemical industries. It is also widely used in agriculture, horticulture and water management. This article will give you a basic understanding of hydraulic gear pump, its working principle and some of the applications it is used in.

Origin and Development of Hydraulic Gear Pump

Hydraulic gear pump is a machine that uses the power of hydraulics to transfer rotational motion. It was first invented in 1795 by Sir William Symington. The modern hydraulic gear pump was developed in the early 1800s.

Working Principle of Hydraulic Gear Pump

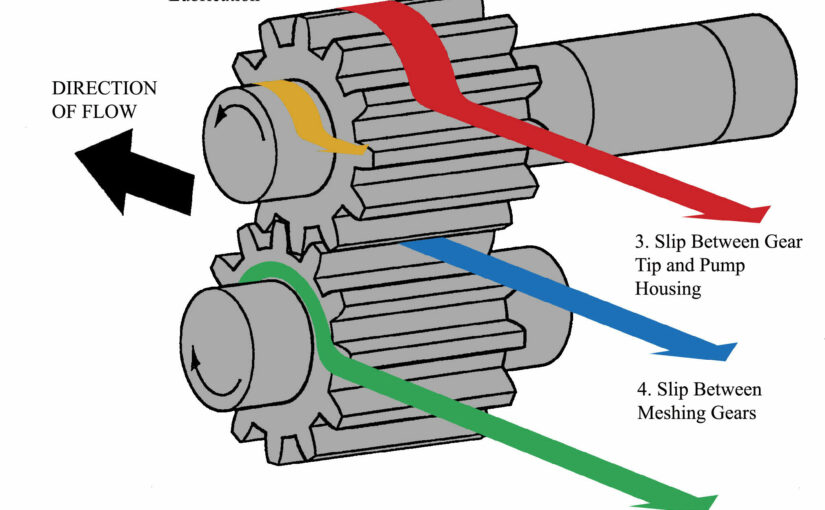

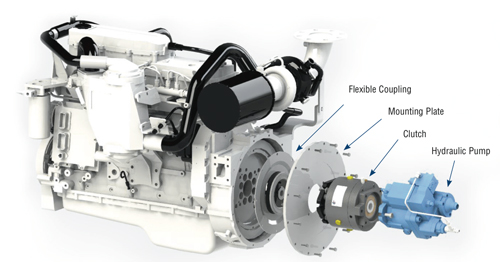

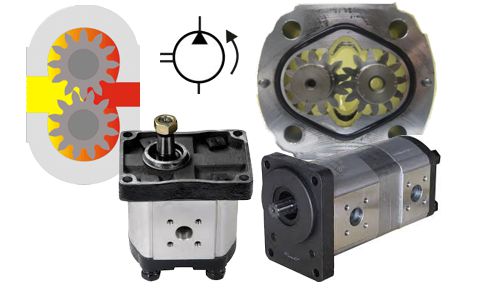

The working principle of a hydraulic gear pump is simple. It consists of two gears that are connected by a shaft. The gears are turned by an engine or motor, and the shaft transfers the rotational motion to the gears. This rotational motion then transfers to the output shaft, which can be used to move objects or liquid.

How does a hydraulic gear pump work?

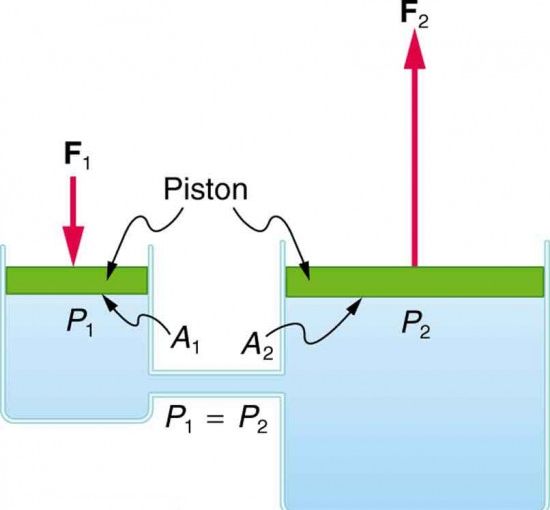

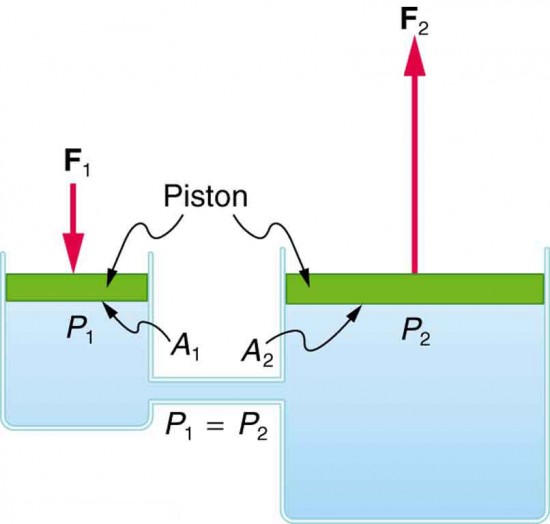

A hydraulic gear pump is a device that uses the power of hydraulics to move objects. A hydraulic gear pump works by using the pressure of the hydraulic fluid to move objects. The hydraulic fluid is pressurized by the engine, and then sent through the pump to move the object.

The engine powers the pump, and the pump uses the pressure of the hydraulic fluid to move the object. The pressure of the hydraulic fluid is controlled by the valve, which allows the flow of the fluid to be regulated.

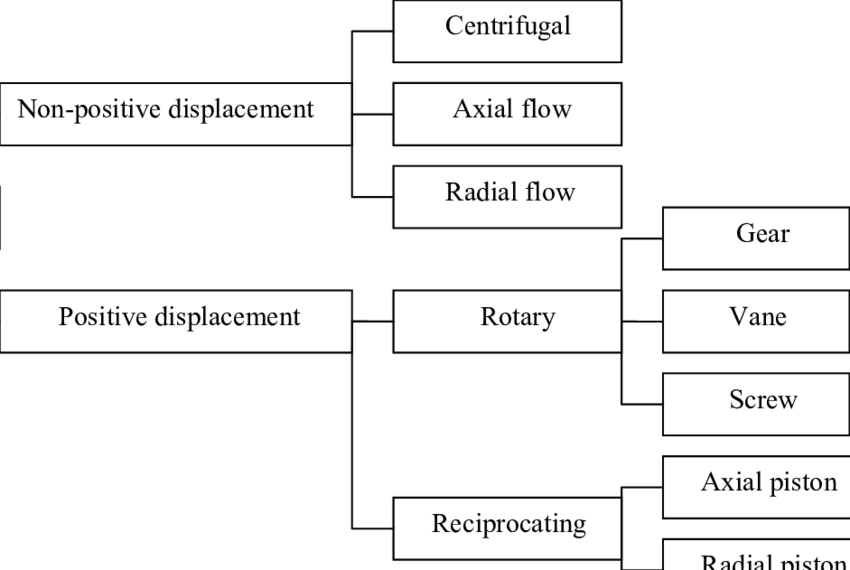

Different types of hydraulic gear pumps

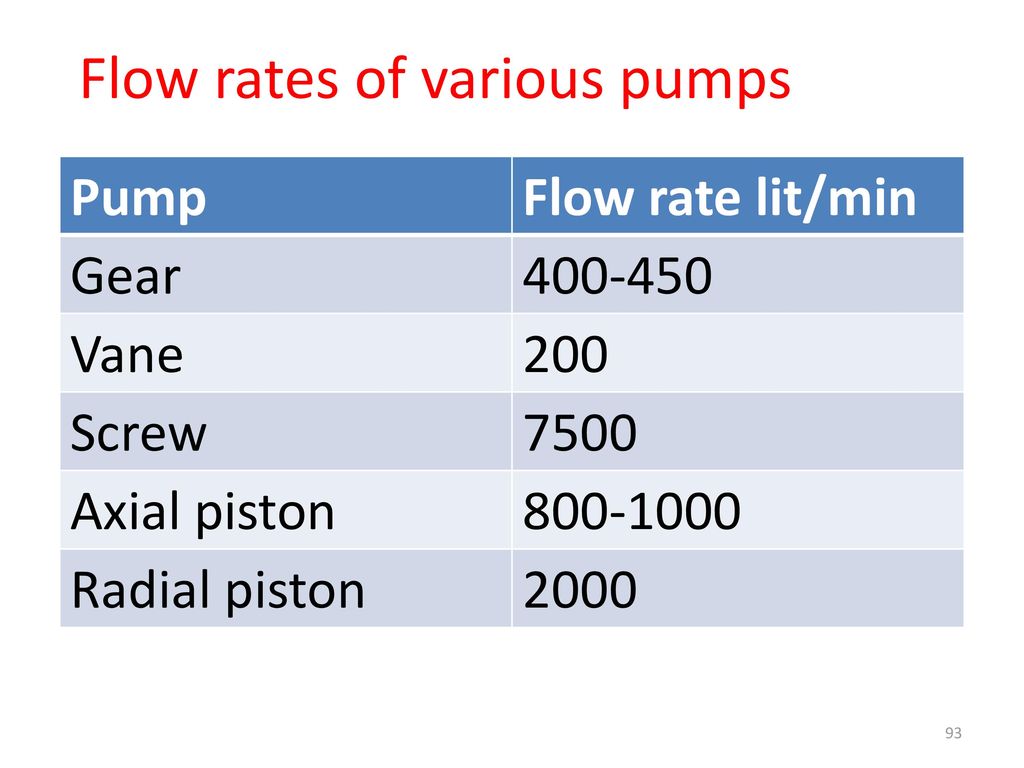

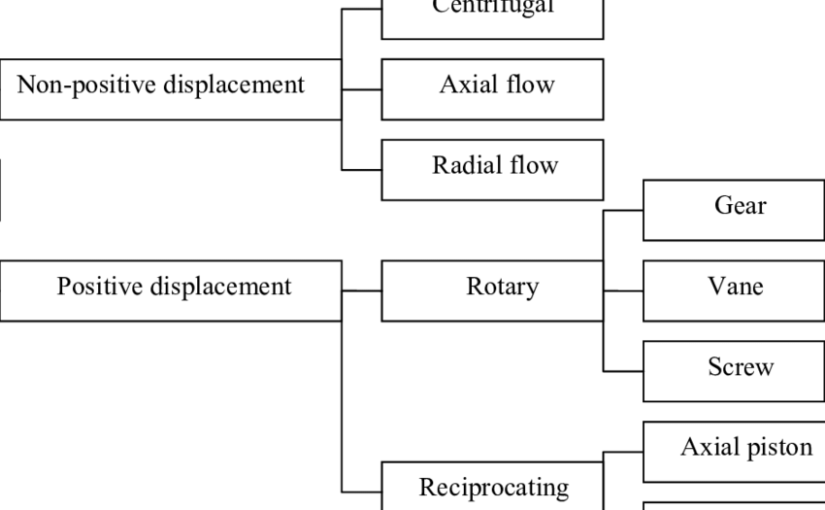

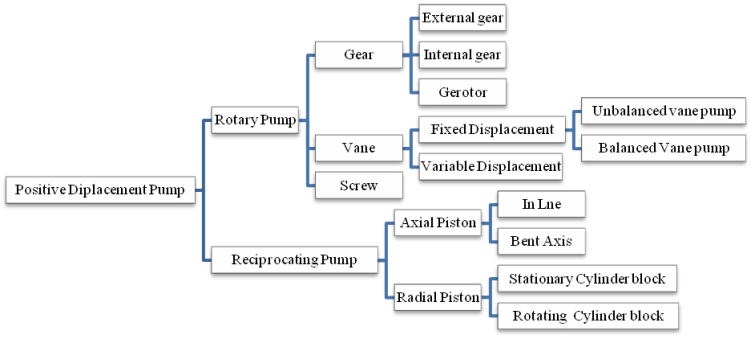

Hydraulic gear pumps provide a means of moving fluid or air at high speed and are widely used in a variety of industries. There are three main types of hydraulic gear pumps: impulse, rotary and centrifugal. Each has its own advantages and disadvantages, which will be discussed below.

Impulse gear pumps are the simplest type of pump and work by using an impulse to move the fluid. They can be used to move fluid at high speeds, but they can also be quite noisy. Rotary gear pumps use a rotating impeller to move the fluid. They are quieter than impulse gear pumps, but they require more power to operate. Centrifugal gear pumps use a spinning impeller to move the fluid. They are the most powerful type of pump and are often used to move large volumes of fluid.

How many gears do they have and what are the gears used for?

A hydraulic gear pump is a machine that uses hydraulic power to move a load. The gears in a hydraulic gear pump are used to change the speed of the movement of the load. Gear pumps are used for a variety of purposes, including moving fluids, removing particles, and generating pressure.

There are many different gears used in a gear pump, depending on the type of load that the gear pump is designed to move. Gear pumps typically use gears that are made out of metal, plastic, or ceramic. Gears used in gear pumps are often sized according to the size of the object that they are designed to move.

Advantages of using a hydraulic gear pump

There are many advantages to using a hydraulic gear pump in your business. Here are just a few:

– They are reliable and durable.

– They are efficient and can move a lot of fluid quickly.

– They can be used in a variety of applications, such as oil drilling and water pumping.

– They are often less expensive than other types of pumps.

Disadvantages of using a hydraulic gear pump

Hydraulic gear pumps can be very efficient when used correctly, but they have some disadvantages that should be considered. The main disadvantage is the need for a reliable power source. Gear pumps can also be difficult to operate, and they can wear out quickly if not properly maintained.

Additionally, gear pumps can be difficult to transfer power from one location to another, and they can also be noisy. Finally, hydraulic gear pumps are not always the most energy efficient option, so they may require more fuel than other types of pumps.

Why are pumps used in hydraulic systems?

Pumps are used in hydraulic systems because they can move a large amount of fluid at a fast pace. When a pump is in use, the fluid that it is pumping will move from one point to another. This is why pumps are so important in hydraulic systems; they help to move the fluid around and keep everything running smoothly.

Pumps can also be used to help control the flow of fluid. When a pump is working, it will push the fluid in one direction or another. This can be used to help control the flow of water or other fluids.

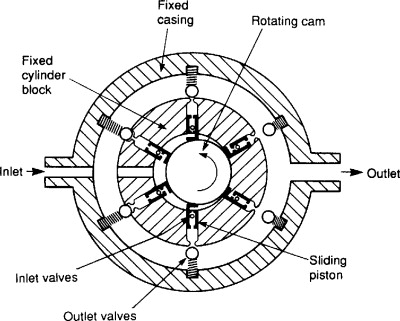

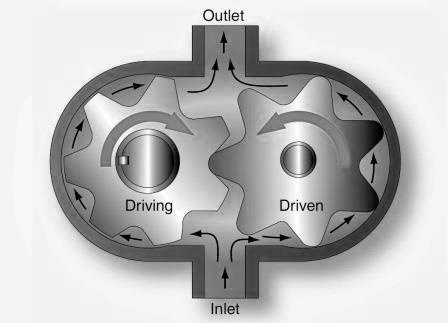

What are the parts inside a gear pump?

Gear pumps are used in many industries to move large amounts of fluid or gas. They consist of a shaft, a gearbox, and a motor. The shaft is the main component that moves the fluid or gas. The gearbox is responsible for the speed and direction of the movement. The motor powers the gear pump.

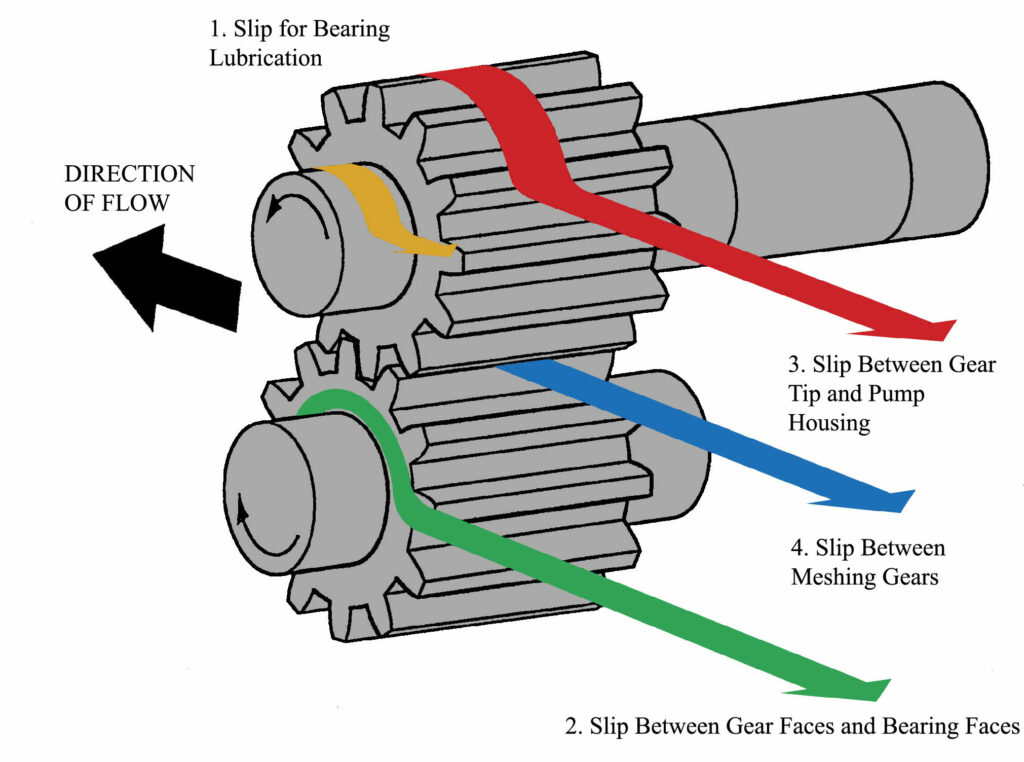

Inside the gear pump there are several parts that work together to make it function. These parts include the shaft, gears, bearings, seals, and impellers. The shaft is the main component that moves the fluid or gas. It has a diameter and a length that is chosen based on the application for which the gear pump will be used. Gears are located on the shaft and they convert rotational motion into linear motion. Bearings are located on each gear and they help to reduce friction between different parts of the gear pump. Seals help to prevent debris from entering the gearbox and causing damage. Impellers help to push fluid or gas through the gears and into the motor.

The speed at which a gear pump moves fluid or gas depends on how much torque is applied to the motor. Torque is measured in inch-pounds (in-lbs). Gear pumps can move fluids or gases at different

Conclusion

A hydraulic gear pump is a machine that uses the power of pressurized fluid to move objects or fluids. They are used in applications like mining, construction, oil and gas production, and water treatment. Understanding how these machines work can help you decide if one is the right tool for your specific application.

What is hydraulic gear pump,please click topkitparts see more