Hydraulic pumps come in two main categories: positive displacement and rotational. Positive displacement pumps use a fluid to push a plunger up and down, while rotational pumps use a belt or rotor to turn the plunger. Both types of pumps have their own strengths and weaknesses, so it’s important to know which one is right for your application.

Hydraulic pumps are classified according to the type of fluid they push – Pumps for liquids and pumps for gases. Let’s take a closer look at each one!

Piston Pump

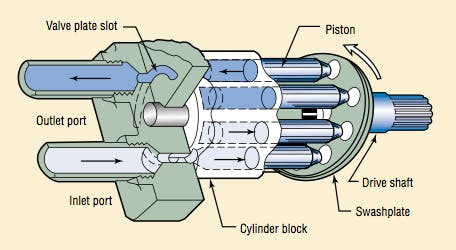

1. Piston pump is a type of hydraulic pump that uses pistons to move the fluid.

2. They are used in industries where high pressures are required, such as mining, oil and gas production, and water treatment.

3. They have many applications in various fields, including agriculture, construction, and manufacturing.

1. Piston pumps are classified according to the type of fluid they operate:

a. Centrifugal pumps are used to move liquids and gases. They are usually found in factories, where they are used to transfer liquids or gases between tanks or drums and the outside world.

b. Pneumatic pumps are used to move air or other gases. They are usually used in warehouses, where they help to move items between different parts of a building.

c. Hydrostatic pumps are used to move water. They are sometimes called water turbines because they use the power of water to turn a turbine. Hydrostatic pumps are often found on large river boats and in hydroelectric dams.

Rotary Pump

There are several different types of hydraulic pumps, each with its own classifications. rotary pumps are the most common type of pump and fall into the classification of displacement pumps.

Displacement pumps use a rotating motion to move the fluid through the pump. This is why they are called displacement pumps: because they displace the fluid from one location to another.

Rotary pumps are also known as reciprocating pumps because they use a rotating motion to push or pull fluid through the pump. They are used in applications where high flow rates are required, such as in chemical and oil refinery plants.

Pneumatic vs Hydraulic

There are two main types of hydraulic pumps: pneumatic and hydraulic. Pneumatic pumps use air pressure to move the fluid, while hydraulic pumps use a liquid to move the fluid.

Pneumatic pumps are used in applications where high pressure is required, such as in compressors or vacuum cleaners. They require a constant supply of air to keep the pump working, which can be a problem in environments with limited air availability, such as aboard ships or on high-altitude mountains.

Hydraulic pumps, on the other hand, are more common in applications where low pressure is required. This is because they use a liquid to move the fluid. This means that they can work in environments with limited air availability, such as inside buildings.

Both types of pumps have their own advantages and disadvantages. Pneumatic pumps are often faster than hydraulic pumps, but they can’t work under very high pressures. Hydraulic pumps are usually more powerful than pneumatic pumps, but they can’t work under very low pressures.

Advantages and Disadvantages of Each Type

There are a variety of hydraulic pumps available on the market. Each has its own advantages and disadvantages. Here is a brief overview of each type:

Piston pumps: piston pumps are the most common type of pump used in industry. They are cheap and easy to operate, and they have low noise levels. However, they are not as efficient as other types of pumps, and they can have limited capacity.

Vane pumps: vane pumps are more efficient than piston pumps, and they have greater capacities. They also produce lower levels of noise. However, vane pumps are more expensive than piston pumps, and they require more maintenance.

Rotary pumps: rotary pumps are the most expensive type of pump, but they offer the highest level of efficiency. They also produce the lowest levels of noise. However, rotary pumps require a lot of space, which limits their use in smaller applications.

How Hydraulic Pumps Work

One type of hydraulic pump is a screw pump. This type of pump uses a rotating screw to move the fluid.

Another type of hydraulic pump is the vane pump. This type of pump uses blades on the rotor to move the fluid.

Still another type of hydraulic pump is the diaphragm pump. This type of pump uses a diaphragm to move the fluid.

Hydraulic pumps are used in a variety of applications, including manufacturing, agriculture, and construction. They are classified according to the type of fluid they move.

Pumps that use hydraulic oil or water to move objects are called hydraulic motors. These pumps operate on the principle of displacement. They use pressure to move a fluid from one location to another.

Pumps that use compressed air to move objects are called pneumatic motors. These pumps operate on the principle of adiabatic compression. They use air pressure to force a fluid through a pipe.

Pumps that use both hydraulic oil and compressed air are called hybrid pumps.

Conclusion

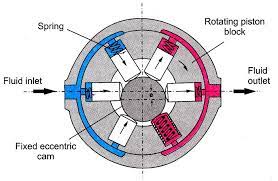

hydraulic pumps can be classified into two categories: open-loop and closed-loop. Open-loop pumps rely on atmospheric pressure to operate, while closed-loop pumps use a piston or cam mechanism to create a displacement of fluid.

What are the 2 classifications of hydraulic pumps. please click topkitparts see more