Hydraulic pumps are an important part of working with fluids, whether they be water, oil, or gas. In this article, we’ll take a look at the two main types of hydraulic pumps and what they’re used for.

Pump Types

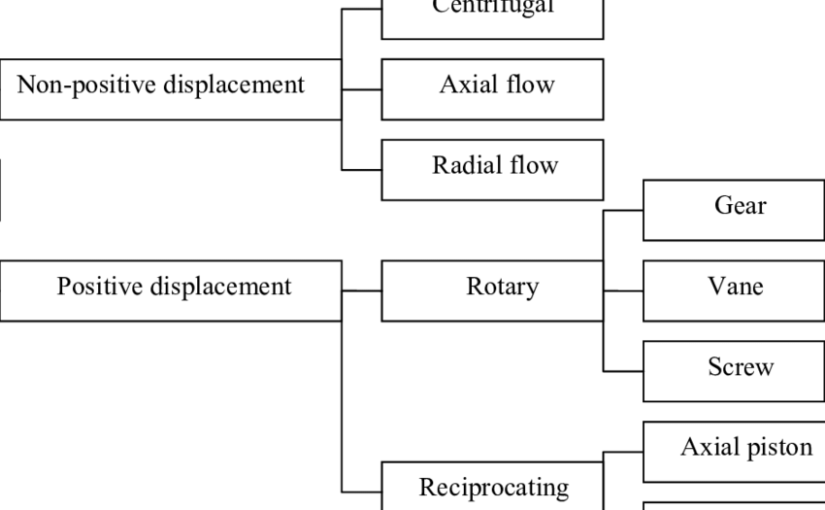

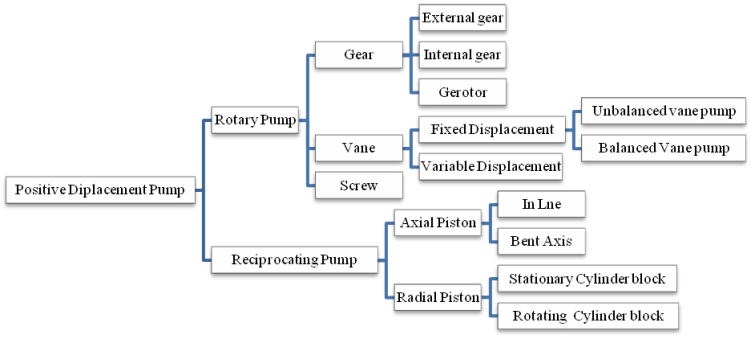

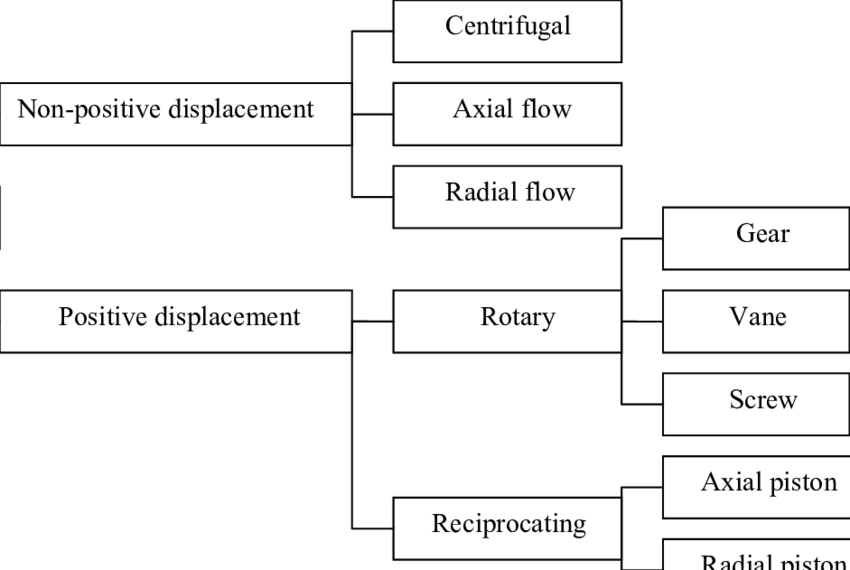

Pump types can be broken down into two main categories: rotary and reciprocating.

Rotary pumps use a spinning disk to move the fluid, while reciprocating pumps use pistons to move the fluid. Rotary pumps are typically used for liquids, while reciprocating pumps are more often used for gases.

What are hydraulic pumps?

Hydraulic pumps are classified based on the type of fluid they use to move the pistons.

Piston pumps use a liquid to move the pistons, while vane pumps use a gas. Vane pumps are used in applications that require high speed, such as in engine oil or water cooling systems.

Piston pumps are used in applications that require low speed, such as hydraulic lift and sewage pumping. They are also used in mining and agricultural applications.

How do hydraulic pumps work?

Hydraulic pumps are often used in industrial settings to move large amounts of water, oil, or other fluid substances. They work by using the power of hydraulics to move a fluid through a system.

There are three different classifications of hydraulic pumps: impulse, rotary, and screw. Impulse pumps are the simplest type of pump and work by using an impeller to create a rotating motion. Rotary pumps use a rotating chamber to produce the motion needed for pumping. Screw pumps use a screw auger to create the rotating motion.

What are the different types of pumps

There are a few different types of hydraulic pumps, each with its own advantages and disadvantages.

Piston pumps are the oldest type of pump, and they work by moving fluid through a piston inside a cylinder. They are good for small jobs where you need to move a lot of fluid quickly, like in water treatment plants or swimming pools.

Rotary pumps are the most common type of pump, and they use a series of rotating discs to move the fluid. They’re good for tasks where you need to move large amounts of fluid slowly, like in oil refineries or factories.

Vane pumps use vanes to move the fluid. They’re good for tasks where you need to move a lot of fluid quickly in one direction, like in water pipes or sewage systems.

What is the difference between a low pressure hydraulic pump and a high pressure hydraulic pump?

1. Low pressure hydraulic pumps are used to pump liquids or gases at a lower pressure than high pressure hydraulic pumps.

2. They are used in applications where the pressure needed is low, like in mining or in manufacturing.

3. High pressure hydraulic pumps are used to pump liquids or gases at a higher pressure than low pressure hydraulic pumps.

4. They are used in applications where the pressure needed is high, like in water treatment or in construction.

Different Uses of Hydraulic Pumps

Hydraulic pumps are used in a variety of different applications. They can be used to move water, oil, gas, or other liquids or gases.

There are four main types of hydraulic pumps: linear, rotary, centrifugal, and volumetric. Each type of pump has its own unique advantages and disadvantages.

Linear pumps are the most common type of pump and they are used to move liquids or gases. Linear pumps work by moving a piston along a cylinder.

Rotary pumps are similar to linear pumps, but they also have a rotor that moves around the cylinder. Rotary pumps are faster than linear pumps, but they also require more maintenance.

Centrifugal pumps work by spinning a blade around a center shaft. Centrifugal pumps are good for moving large quantities of fluid quickly.

Volumetric pumps are used to transfer small amounts of fluid at a time. Volumetric pumps are usually smaller than other types of pumps and they don’t require as much power.

How to Identify Types of Hydraulic Pumps

There are many different types of hydraulic pumps, and each has its own unique classification.

One way to identify the type of hydraulic pump is to look at its working principle. Some pumps work using a fluid that is forced through a nozzle by a pressurized steam or gas, while others use a fluid that is pressurized by the engine to drive the pump.

Another way to identify the type of hydraulic pump is by its application. Hydraulic pumps are used in a variety of industries, including manufacturing, transportation, and infrastructure maintenance.

Tips for using hydraulic hydraulic pumps.

1. Tips for using hydraulic hydraulic pumps:

When using a hydraulic pump, it is important to be aware of the various classifications of the pump. This will help you to choose the right pump for your needs.

There are three main types of hydraulic pumps: oil-free, oil-fed, and hybrid. Each type has its own benefits and drawbacks. Here are some tips to help you choose the right type of pump for your application:

1) Oil-free pumps: These pumps operate without any oil, which makes them compact and reliable. They are ideal for applications where space is limited or where there is no risk of contamination. However, they are not as efficient as oil-fed pumps and can take longer to reach maximum output.

2) Oil-fed pumps: These pumps use oil to drive the piston and generate power. They are more powerful than oil-free pumps and are perfect for applications that require high levels of output or where there is a risk of contamination. They can be noisy, but they are also more efficient than hybrid pumps.

3) Hybrid pumps: These pumps combine features from both oil-fed and oil-free pumps. They are medium in terms of

Conclusion

There are two types of hydraulic pumps, internal and external. Internal pumps are located within the machine itself, while external pumps are attached to the machine via a hose or pipe.

What are the 2 classifications of hydraulic pumps,please click topkitparts see more