Hydraulic pumps are an important part of many modern industrial facilities, and for good reason. They’re incredibly efficient at moving large amounts of fluid around, and they’re able to do so with precision and speed. In this article, we’ll take a look at the main types of hydraulic pumps, and explain why they’re so valuable.

What is a Hydraulic Pump?

hydraulic pumps are used to move fluids, usually water or oil, up and down a pipe. There are many different types of hydraulic pumps, each with its own advantages and disadvantages. Some of the most common types of hydraulic pumps include centrifugal pumps, piston pumps, and rotary pumps.

Centrifugal Pumps

Centrifugal pumps are the most common type of hydraulic pump. They work by using the principles of gravity to move the fluid. Centrifugal pumps have a spinning rotor that is surrounded by a chamber filled with the fluid you want to pump. As the rotor spins, it causes the fluid to move around it. Centrifugal pumps are good for small jobs because they are very fast and efficient. However, they are not very good at moving large amounts of fluid uphill.

Piston Pumps

Piston pumps work similar to centrifugal pumps, but they use pistons instead of rotors. Pistons push and pull on a plunger inside the pump chamber. This action causes the fluid to move up and down the pipe. Piston pumps are good for moving large amounts of fluid uphill, but they are not as fast as centrifugal pumps.

How do hydraulic pumps work?

Hydraulic pumps are one of the most important types of pumps used in industry. They are used to move fluid, such as water or oil, between different areas. They work by using the power of pressurized fluids to move objects.

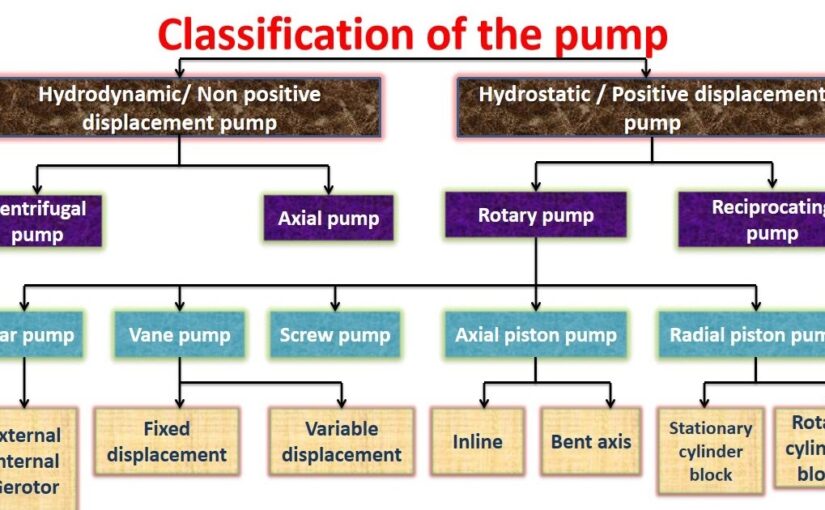

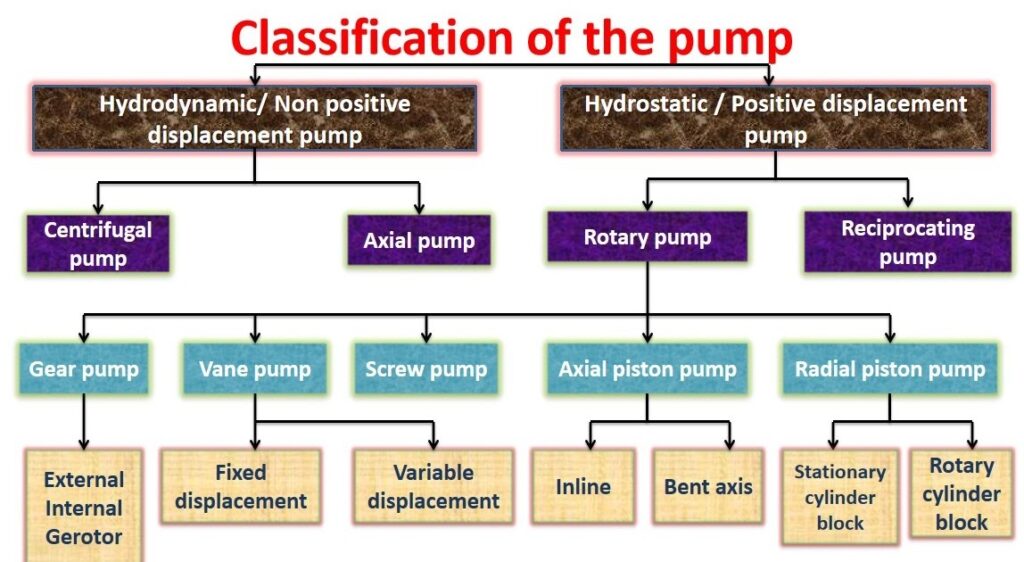

There are several different types of hydraulic pumps, each with its own specific purposes. Here are the main types:

-Piston pump: This type of pump uses pistons to move the fluid. They are popular for applications where high pressure is needed, such as in mining or drilling operations.

-Rotary pump: Rotary pumps use a rotating disk to move the fluid. They are mainly used for applications where high flow rates are required, such as in water treatment plants or factories.

-Vane pump: Vane pumps use vanes to move the fluid. They are mainly used for applications where low pressure is needed, such as in oil refineries or water treatment plants.

Some common uses for hydraulic pumps

There are a few main types of hydraulic pumps: rotary, vane, and screw. Each type has its own advantages and disadvantages.

Rotary pumps work by using a rotor to push fluid through a discharge pipe. They’re usually smaller and faster than vane or screw pumps, but they can be more expensive.

Vane pumps use vanes to move the fluid. They’re usually bigger and slower than rotary or screw pumps, but they can be more efficient.

Screw pumps use screws to move the fluid. They’re usually the biggest and slowest of the three types, but they’re also the most durable.

Description of different types of hydraulic pumps

Hydraulic pumps are essential devices in any machine or system that requires motion. There are many different types of hydraulic pumps, each with its own unique features and benefits. This article will discuss the three main types of hydraulic pumps: rotary, reciprocating, and pistonic.

Rotary hydraulic pumps are probably the most commonly used type of pump. They work by turning a rotor that churns the liquid inside the pump. This action generates force that causes the pump to move objects or fluids. Rotary hydraulic pumps can be used in a variety of applications, from water pumps to printing presses.

Reciprocating hydraulic pumps are similar to rotary pumps in that they use a rotor to generate force. However, reciprocating pumps use pistons instead of a rotor. This makes them more powerful and efficient than rotary pumps, and they’re often used for larger applications like mining machines and construction sites. Reciprocating pumps can also be used to move liquids and gases, making them a versatile choice for industrial applications.

Pistonic hydraulic pumps are a variant of reciprocating pumps that use pistons instead of blades to move the fluid. Pistonic pumps are less common than

Advantages and disadvantages of each type

There are many types of hydraulic pumps and it can be difficult to decide which one is the best for your application. This article will cover the main advantages and disadvantages of each type of pump and help you make an informed decision.

Piston Pumps: piston pumps are the most common type of pump and they are used in a variety of applications, including water delivery, wastewater treatment, mining, oil and gas production, and chemical processing. They are relatively easy to operate and maintain, making them a good choice for small businesses.

The main advantage of piston pumps is their low cost. They are also relatively efficient when it comes to transferring fluid volume, making them a good choice for applications where high throughput is necessary.

One disadvantage of piston pumps is their slow speed. This can be a problem in applications where fast response times are necessary, such as in manufacturing or in medical applications. Additionally, piston pumps can be susceptible to wear and tear over time, so they should be replaced periodically if reliability is a important factor.

Rotary Pumps: rotary pumps are used in fluids that require high pressure (higher than 10 MPa) or high flow rates ( greater than 100 l/min). They are

Ways to carry out tasks using different types of hydraulic pumps

hydraulic pumps are widely used in various fields, and there are many different types of pumps to choose from. Here are some of the most common types of pumps:

– Piston: The piston pump is the oldest type of pump, and it works by using a piston to move the fluid. This type of pump is good for tasks that don’t require a lot of pressure, like moving water or oil.

– Rotary: Rotary pumps use a rotating disk to move the fluid. This type of pump is good for tasks that require high pressure, like moving water or oil up a hill.

– Vane: Vane pumps use a series of blades to move the fluid. This type of pump is good for tasks that require speed, like filling a tank quickly.

Which Type of Pump is Right for Your Project?

There are many types of hydraulic pumps available on the market, each with its own unique strengths and weaknesses. Before you choose a pump, it’s important to understand the different types and their purposes. Here are the main types of hydraulic pumps:

1) Pumps driven by motor: These pumps are most commonly found in industrial settings, where they’re used to distribute fluids such as oil, water, or gas. They’re usually fast and efficient, but can be expensive to operate.

2) Pumps driven by hydraulics: Hydraulic pumps use the power of hydraulic fluid to move objects. They’re typically slower than motor-driven pumps, but are more reliable and often more affordable. They’re also useful for applications where speed isn’t as important, like water distribution in homes.

3) Pumps driven by wind: Some pumps powered by wind energy use blades that rotate to create motion. This type of pump is good for applications where speed is important, like pumping water from a river or offshore drilling site. However, they can be less efficient than other types of pumps and aren’t always available in locations where electricity is plentiful.

4) Pumps driven

Conclusion

Hydraulic pumps are one of the most versatile and commonly used types of pumps. They are used in a variety of industrial and commercial settings, including agriculture, construction, oil & gas extraction, water treatment, printing and textile production. There are several different types of hydraulic pumps on the market today, each with its own advantages and disadvantages. If you’re looking to purchase a new pump for your business or need to replace an existing pump, be sure to research which type is best suited for your needs.

What are the main types of hydraulic pumps, please click topkitparts see more