Hydraulics are a type of engineering that use fluid mechanics to create motion. Hydraulic systems can be used in a variety of ways, from simple pumps to more complicated water turbines and hydraulic pumps. Understanding how hydraulics work can help you troubleshoot malfunctions and optimize performance.

Causes of hydraulics running slow

Slow hydraulics can be caused by many different issues. Here are a few of the most common causes:

-A clogged or dirty filter: This is the most common cause of slow hydraulics. Over time, dirt, dust, and other particles can build up in the filter and prevent the hydraulic fluid from flowing freely. This can cause the pump to work harder to move water, which in turn can lead to decreased efficiency and increased wear on the machinery. It’s important to keep your filter clean and free of debris to ensure smooth operation.

-A worn pump: A worn pump can also cause hydraulics to run slowly. Over time, the metal gears inside the pump can become rusty and damaged, leading to decreased efficiency and increased wear on the machinery. It’s important to regularly inspect your pump for signs of wear and replace any parts that need replacement.

-Damaged piping: Broken or misaligned pipes can also cause hydraulics to run slowly. When water flows through a pipe at a certain speed, it creates a pressure difference that helps move objects along the pipe. If one section of the pipe is damaged significantly more than others, this pressure difference can no longer maintain its integrity,

How hydraulics work

Hydraulics are an essential part of modern life. They are used for everything from moving cars to controlling water flow in factories. But how do hydraulics work?

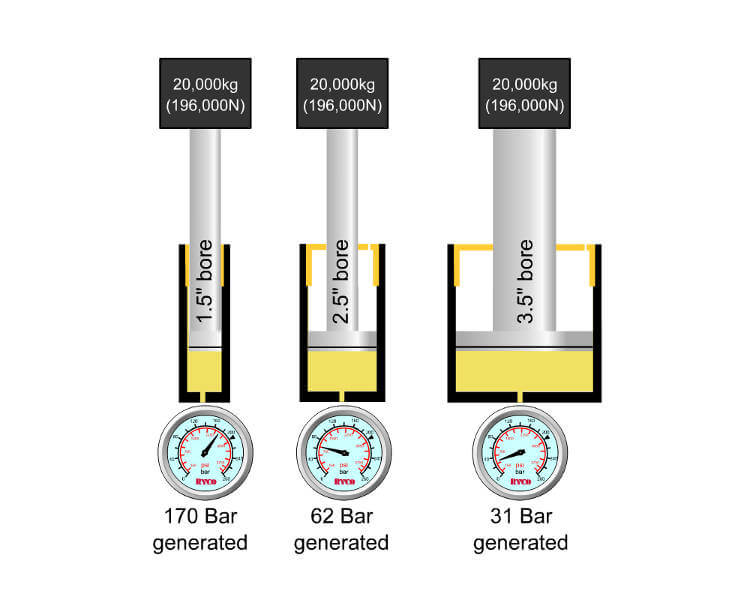

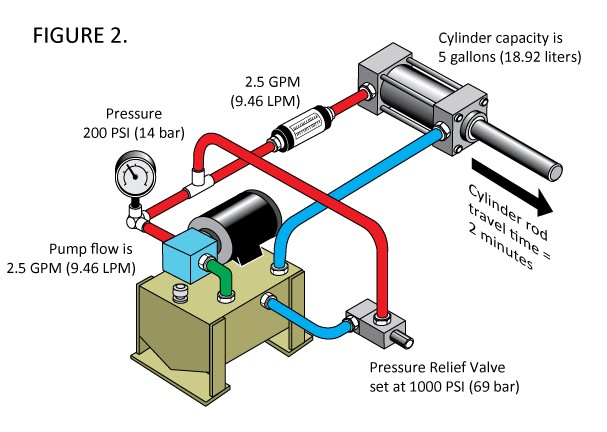

The basic principle behind hydraulics is that a fluid can be moved through a pipe by exerting a force on the fluid. This force is usually generated by a motor. The speed at which the fluid moves is controlled by the amount of pressure that is applied to it.

There are several factors that can affect the speed at which hydraulics work. These include the size and shape of the pipes, the quality of the fluids being moved, and the efficiency of the motors.

How to troubleshoot hydraulics running slow

If your hydraulic system is running slowly, there are a few things you can do to troubleshoot the issue. First, check the fluid level and make sure it’s at the recommended level. Next, check for air bubbles in the system and remove them using a vacuum cleaner. Finally, check for blockages in the system and clear them using a plunger or snake.

Solutions to slow hydraulics

There are a few potential causes of hydraulics running slow, and in most cases, solving the issue is as simple as adjusting a few settings. Here are some solutions to common problems:

– Dirty or clogged filters: Remove any dirt or debris that may be blocking the filter’s passages and run a cleaning cycle. If this doesn’t resolve the issue, replace the filter.

– Faulty pump: If the pump is not operating at its full potential, it may be due to a worn or defective motor. In this case, replacing the pump may be the best solution.

– Low fluid level: Check the fluid level and top up as needed. Hydraulic fluids can lose their potency over time if not properly maintained.

Types of hydraulics

Hydraulic systems can run slowly for a variety of reasons. Understanding the causes and solving the problem can help restore normal operation.

There are three main causes of hydraulics running slowly: fluid obstruction, pump problems, and valve problems.

Fluid Obstruction: Fluid can get trapped in system components, such as valves, pipes, and filters. This can cause the system to run slowly or even stop working altogether. To prevent this from happening, regularly check system components for debris and blockages. If there is an obstruction, remove it using a standard hydraulic tool or cleaning procedure.

Pump Problems: If the pump is not working properly, the system will not be able to transfer enough power to move the fluid. This can cause everything from slow operation to complete stoppage. To diagnose and solve pump problems, use diagnostic tools like flow meters and pressure gauges. If necessary, replace the pump.

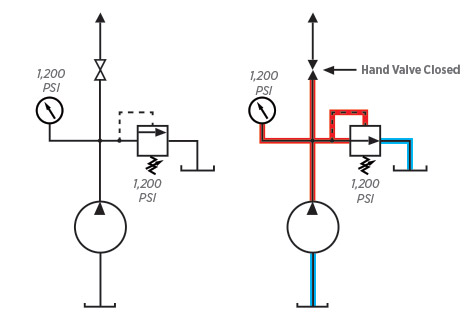

Valve Problems: Valves control how much power is transferred between the pump and engine. If they are not opening or closing properly, the system will not be able to operate at its full potential. To diagnose and solve valve problems, use diagnostic tools like pressure gau

Improving hydraulic performance

Hydraulic systems are often designed to operate slowly in order to conserve energy. However, there are a number of ways to improve hydraulic performance. One way is to identify and correct any causes of slow operation. Here are some common causes of sluggish hydraulics:

-Low fluid level: A low fluid level can cause the system to fail due to pump or valve failure. Check the system level every time you make a change to the hydraulic system.

-Air pockets: Air pockets can form in lines and hoses, causing the system to operate slowly or even stop working entirely. Remove any air pockets by using a vacuum cleaner and a hose, or by using a plunger.

-Wear and tear: Overuse or improper installation can cause wear and tear on components, leading to sluggish performance. Regular inspections will help prevent this type of problem.

Conclusion

Slow hydraulics can be a frustrating problem to deal with, but fortunately there are ways to diagnose and fix the issue. In this article, we’ll explore some of the causes of slow hydraulics and how you can find and fix them. Hopefully, by the end of this article you will have a better understanding of what is causing your hydraulics to run slow and be able to take steps towards fixing the issue.

What causes hydraulics to run slow. please click topkitparts see more