If you’ve ever been curious about what would happen if you ran a hydraulic pump backwards, read on! In this article, we’ll explore the physics behind how a pump works and see what could happen if you reversed its flow. We’ll also provide some tips on how to avoid possible damage and safely experiment with pumps.

What is a hydraulic pump?

What happens if you run a hydraulic pump backwards?

Hydraulic pumps are used in many different industries to move fluids or gases. When operated correctly, hydraulic pumps can provide years of reliable service. However, if a hydraulic pump is operated in the wrong direction, it can cause serious damage. In this article, we’ll discuss what happens if you run a hydraulic pump backwards and what to do if it happens.

A typical hydraulic pump consists of two main parts: the input and output cylinders. The input cylinder is connected to the source of power (e.g., a motor), while the output cylinder is connected to the object being moved (e.g., a container). When power is applied to the input cylinder, fluid is forced into the output cylinder and begins moving it forward. To move an object using a hydraulic pump, you first need to set up the equipment and calibrate it. Next, you would start the engine and apply power to the input cylinder. The faster the engine runs, the greater the force will be applied to the output cylinder, which will move the object forward.

If you ever hear your hydraulic pump making unusual noises or see smoke coming from it, it’s important to

How does a hydraulic pump work?

A hydraulic pump is a device that uses the power of hydraulic fluid to move objects. When you run a hydraulic pump backwards, you’re not doing anything illegal. In fact, most hydraulic pumps are designed to work in either direction. However, if you accidentally run a hydraulic pump backwards and cause it to overheat, it could cause serious damage.

Why do hydraulic pumps turn the other way?

A hydraulic pump is an energy-intensive machine that helps move fluids and other materials. When a hydraulic pump is operating normally, the pistons inside turn clockwise to create motion. However, if something goes wrong and you accidentally run the pump backwards, the pistons will start to turn counterclockwise and the machine will stop working.

There are several reasons why running a hydraulic pump in reverse could cause damage or even failure. The backward motion of the pistons can cause them to hit one another, which can break them or cause them to jam. Additionally, the fluid being pumped can become extremely hot and pressurized, which can also cause problems. If a hydraulic pump is not properly maintained and operated, it could eventually fail altogether due to this type of error.

How do hydraulic pumps work in reverse?

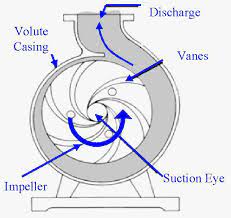

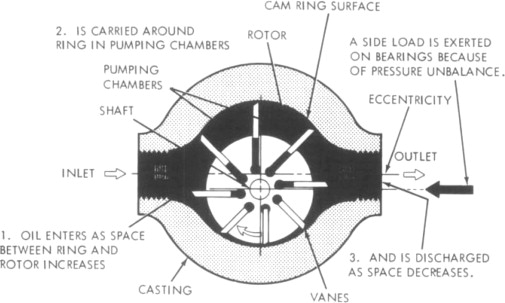

Hydraulic pumps work by moving a fluid (usually oil or water) through an axial channel. When the pump is working normally, the fluid is forced out of the inlet and towards the outlet through the impeller. As the impeller spins, it creates a forward motion of the fluid which is then transferred to the rotating drive shaft. This forward motion powers the pump. However, if you were to run a hydraulic pump in reverse, it would work exactly the same way as a normal pump except that instead of creating a forward motion, it would create a backwards motion.

The backward motion of a hydraulic pump is created by reversing the flow of oil or water through the impeller. In order for this to happen, there must be some connection between the input and output shafts of the pump. This connection can be either physical or virtual. If there is a physical connection between the shafts, then running the pump in reverse will cause power to be transferred from the output shaft to the input shaft. Virtual connections are created when one engine controls both engines on a machine. In this case, if you run one engine in reverse, then both engines will automatically start running in reverse.

Why would someone run a hydraulic pump backwards?

If you run a hydraulic pump backwards, you’ll likely damage the pump and the system it’s powering. Backward flow of fluid through a system can cause serious damage, including to components like pumps, valves, and pipelines.

There are many reasons why someone might try to run a hydraulic pump backwards, but the most common is to create a small amount of pressure in order to force something else, like fluid or air, out of a system. Backward flow through a system can also lead to cavitation, which is when tiny bubbles form and severely damage components.

Is there an easy way to run a hydraulic pump backwards?

If you run a hydraulic pump backwards, it may damage the pump or release harmful chemicals. Additionally, reversing the flow of fluid can cause a loss of pressure, which can lead to an accident. If you are unsure whether or not your hydraulic pump can be reversed, consult with a professional.

How to Reverse a Hydraulic Pump

If you run a hydraulic pump backwards, the fluid can cause serious injury. The pressure from the fluid can cause the pump to overheat and may even explode. If you are unsure whether or not your pump can be reversed, consult with a mechanic.

1. Verify that the pump can be reversed by checking the manufacturer’s instructions.

2. Disconnect the power supply to the pump.

3. Remove the cap and hose from the pump discharge port.

4. Connect tubing from the pump discharge port to a high-pressure source, such as a gasoline tank or compressor.

5. Connect tubing from the high-pressure source to the pump inlet port.

6. Reconnect the power supply to the pump.

Conclusion

If you’re ever in a situation where you need to run a hydraulic pump backwards, be sure to do so safely. Doing so can damage the pump and even result in serious injury. If you’re unsure whether or not your hydraulic pump can be run in reverse, consult with an expert before proceeding.

What happens if you run a hydraulic pump backwards,please click topkitparts see more