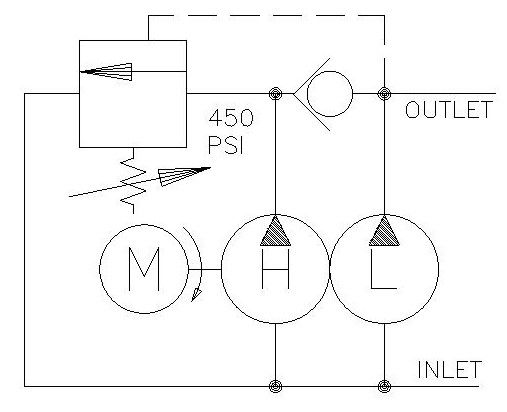

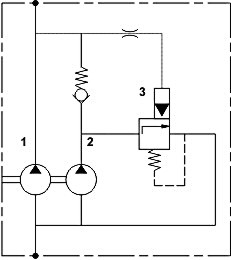

2 stage hydraulic pump is a type of pump that uses two sets of pistons to move the fluid. It has two advantages over single-stage pumps: greater flow capacity and improved efficiency.

What is a hydraulic pump?

A hydraulic pump is a machine that uses hydraulic pressure to move things. It is a type of engine, and it is used to power many different types of machines.

A hydraulic pump consists of two parts: the cylinder and the plunger. The cylinder is the part that actually pumps the fluid. The plunger is the part that moves the fluid. The piston in the cylinder moves up and down, and this causes the fluid to flow into and out of the plunger.

Hydraulic pumps are used in a variety of different ways. They are used to power engines, pumps, and other machines. They are also used in industries like construction, manufacturing, and agriculture.

What are the Types of Hydraulic Pump?

1. A hydraulic pump is a machine that uses pressure and a reservoir of fluid to move something.

2. There are two main types of hydraulic pumps: stage and rotary.

3. Stage pumps are used to move large objects, like ships or trains. They use a series of pistons to move the fluid.

4. Rotary pumps are used to move small objects, like oil or water. They use a shaft that turns to create the pressure needed to move the fluid.

How Does a Hydraulic Pumps Work?

A hydraulic pump is a device that uses hydraulic pressure to move fluids or objects. It works by using the power of a fluid flow to create movement.

When you turn on a faucet, the water pressure inside the hose causes the water to move from the source to the outlet. The same thing happens with a hydraulic pump. The hydraulic pressure inside the pipeline causes the liquid to move from the source to the target.

There are two main types of hydraulic pumps: centrifugal and reciprocating. Centrifugal pumps use spinning blades to create a high-pressure flow. Reciprocating pumps use pistons that move back and forth inside a pipe. They are used for tasks like pumping water, gasoline, oil, or air.

What is a 2 stage hydraulic pump?

A 2 stage hydraulic pump is a type of pump that can move fluid from one location to another. The first stage of the pump moves the fluid, and the second stage helps to keep the fluid moving.

2 stage hydraulic pumps are commonly used in industries such as oil and gas, food processing, and water treatment. They are also used in many other types of businesses.

2 stage hydraulic pumps are very versatile tools. They can be used to move a variety of fluids, including water, oil, and gas. They can also be used to move materials in manufacturing plants and other industrial settings.

2 stage hydraulic pumps are reliable machines. They are able to handle a wide range of conditions and pressures. They are also able to operate at high speeds and in a variety of environments.

If you are looking for a reliable machine that can help you solve your industrial problems, a 2 stage hydraulic pump is the right option for you.

Uses of a 2-stage hydraulic pump

A 2-stage hydraulic pump is a type of pump that is used to move liquids and gases. It is typically used in industries such as chemical, oil and gas, pulp and paper, and food processing.

2-stage hydraulic pumps are divided into two categories: single-stage and double-stage pumps.

Single-stage pumps are the most common type of pump and they use one stage to move the liquid or gas. This means that the first stage uses pressure to push the liquid or gas forward.

Double-stage pumps use two stages to move the liquid or gas. The first stage uses pressure to move the liquid or gas forward, while the second stage uses velocity to push the liquid or gas through the pump. This makes it possible to move larger volumes of liquids or gases than single-stage pumps.

Tips for buying a 2 stage pump

If you are looking for a pump that can handle a variety of tasks, a 2 stage pump might be the perfect choice for you. These pumps are often used in industrial settings, where they are needed to move large amounts of water, oil, or other liquids.

There are a few things to consider when purchasing a 2 stage pump. First, make sure that the pump has the necessary specifications. Second, make sure that the pump is compatible with your specific application.

Finally, be sure to consult with an expert if you have any questions about choosing the right 2 stage pump for your needs. They can help you choose the best option for your specific situation.

Applications of the 2 stage hydraulic pump

A stage hydraulic pump is a machine that is used to move fluids or solids. It is also known as a two-stage pump because it has two stages. The first stage moves the fluid or solid, and the second stage performs the actual work.

There are many different applications for stage hydraulic pumps. They can be used in factories, oil refineries, and other industrial settings. They are also used in transportation systems, including pipelines and ships.

The main advantage of a stage hydraulic pump is its versatility. It can be used to perform many different tasks quickly and efficiently.

Why do you need a 2 stage hydraulic pump?

A two stage hydraulic pump is a type of pump that is used to move fluid from one location to another. This type of pump has two pistons that push and pull the fluid. The pistons are connected by a shaft, which allows the pump to move the fluid.

A two stage hydraulic pump is often used in commercial settings. It is often used to move liquids and gases. The two stage hydraulic pump is also used in agricultural settings to move water and fertilizer.

There are many different applications for a two stage hydraulic pump. If you need a pump that can handle high volumes of fluid, a two stage hydraulic pump is the perfect option for you.

Conclusion

2 stage hydraulic pump is a type of pump that uses two sets of pistons to pressurize and discharge fluid. This type of pump can be used in a variety of industries, such as oil and gas, water resources, mining, food processing and chemical production.

What is 2 stage hydraulic pump,please click topkitparts see more