Hydraulic pumps are a key component of many industrial and commercial applications, ranging from water and gas pipelines to machine tools. As the demand for these pumps increases, so does the need for manufacturers to develop more efficient designs. In this article, we take a look at five of the most efficient hydraulic pumps on the market today.

What is a hydraulic pump?

A hydraulic pump is an engine that uses pressurized fluid to move objects. They are often used in construction, mining, and manufacturing. They come in different sizes and types, but all share one common goal: to make things move.

A hydraulic pump works by using the pressure of the fluid to push and pull objects. The most common type of hydraulic pump is the piston pump. It uses a piston to move the fluid through the engine. This type of pump is relatively slow, but it’s also very efficient.

Another common type of hydraulic pump is the rotary vane pump. This type of pump uses a series of blades to move the fluid through the engine. This type of pump is faster than a piston pump, but it’s also less efficient.

However, there are also hybrid pumps available that combine features from both types of pumps. This makes them a little bit faster than either type of pump on its own, but still very efficient.

Types of hydraulic pumps

Hydraulic pumps can be categorized by the way they convert power into motion: centrifugal, axial flow, and vane type. Centrifugal pumps use a spinning rotor to create motion; axial flow pumps use a screw or impeller to move fluid; and vane type pumps use vanes to direct the fluid.

centrifugal pump

The centrifugal pump is the most common type of hydraulic pump and is used in applications such as mining, construction, and agriculture. The rotor uses centrifugal force to move the fluid. This type of pump is easy to operate and has low operating costs, but it can only move a small amount of fluid at a time.

axial flow pump

The axial flow pump is similar to the centrifugal pump in that it uses a spinning rotor to create motion. However, the axial flow pump uses a screw or impeller to move the fluid instead of a rotor. This makes it better suited for applications that require high volumes of fluid movement, such as water treatment plants.

vane type pump

The vane type pump is used most often in industrial applications because it is very efficient at moving large amounts of fluid. The vane

How hydraulic pumps work

Hydraulic pumps are one of the most efficient types of pumps used in industry today. They are able to move a large amount of fluid with very little energy input. This is why they are so commonly used in industries such as oil and gas production, water treatment, and mining.

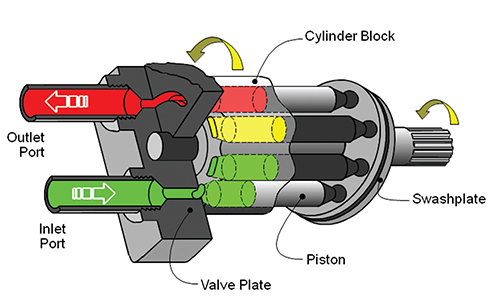

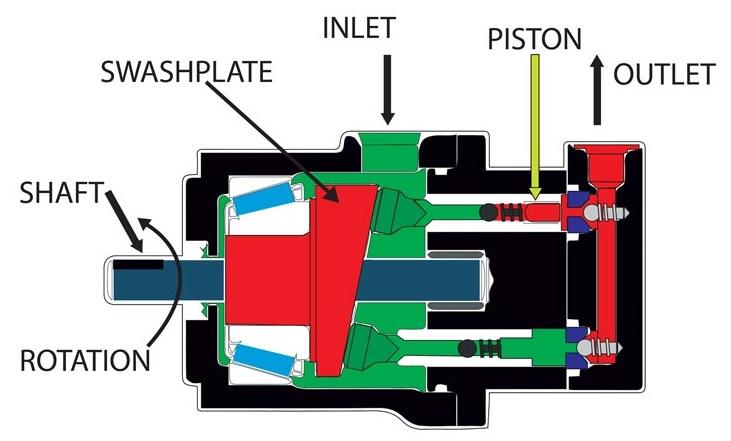

The basic principle behind a hydraulic pump is that a fluid is forced through a series of tubes by a rotating cylinder. This rotating cylinder creates a pressure difference between the inside and outside of the tube. This pressure difference causes the fluid to flow through the tube.

There are many different types of hydraulic pumps available on the market today, but all of them operate on the same basic principle. The main difference between them is the way they create pressure inside the tubes.

piston pump

A piston pump works by using pistons to create pressure inside the tubes. This type of pump is usually less efficient than other types, but it is still popular due to its low price tag.

cone style pump

A cone-style pump works by using a series of cones to create pressure inside the tubes. This type of pump is usually more efficient than piston pumps, but it can be more difficult to operate.

Advantages and Disadvantages of Different Hydraulic Pump Types

Hydraulic pumps are the most efficient type of pump for transferring fluid substances. They are able to move a large amount of fluid with a small amount of energy, which makes them an ideal choice for applications that require high throughputs. However, there are several different types of hydraulic pumps available on the market, and each has its own advantages and disadvantages.

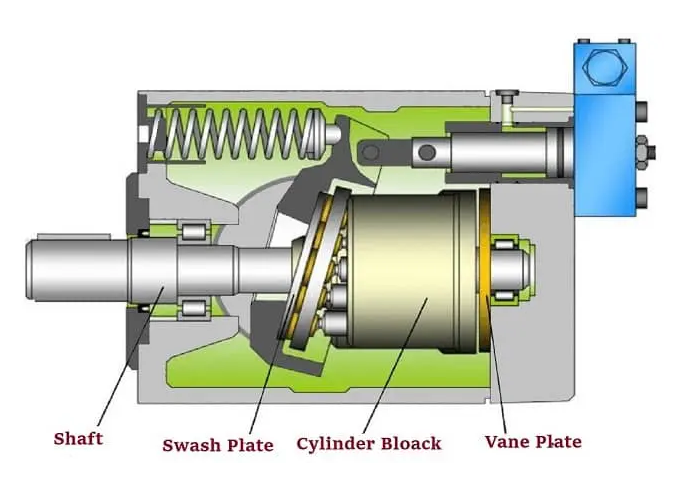

The two main types of hydraulic pumps are vane pumps and piston pumps. Vane pumps use a series of vanes to move the fluid, and they are relatively small and lightweight. They are also efficient, but they can be difficult to operate. Piston pumps use pistons to move the fluid, and they are larger and more expensive than vane pumps. They are also more difficult to operate, but they are more efficient than rotary or axial piston pumps.

Another factor to consider when selecting a hydraulic pump is the horsepower rating. Higher horsepower ratings mean that the pump can move more fluid with each stroke, which is desirable in high-volume applications. However, higher horsepower ratings also means that the pump will require more energy to operate, which may increase the cost of the pump.

How to Choose the Most Efficient Hydraulic Pump for Your Application?

When it comes to choosing the most efficient hydraulic pump for your specific application, there are a few things to keep in mind. Here are four key points to keep in mind when selecting a hydraulic pump:

1. Power density – The power density of a hydraulic pump determines how much work it can perform per unit of energy. Higher power densities mean the pump can perform more work in a shorter amount of time, which is important for applications that require high speed or high pressure output.

2. Speed – Pump speed is also important, as higher speeds means the pump can move more fluid faster. This is especially important for high-volume applications, where the faster the fluid moves, the less chance there is of clogging or contamination.

3. Pressure – The pressure at which a pump operates is also important. Higher pressures mean the pump can move more fluid with less energy expenditure, which is beneficial for applications that require high volumes or high pressures without sacrificing speed or efficiency.

4. Noise – Finally, noise levels are also important considerations when selecting a hydraulic pump. Low noise levels mean less wear and tear on equipment, and greater productivity overall for those working with the pump.

Conclusion

A hydraulic pump is an essential piece of machinery in any industrial or commercial setting, but they can also be used in residential applications. In this article, we will take a look at some of the most efficient hydraulic pumps on the market and discuss their various benefits. We hope that this information will help you find the perfect hydraulic pump for your specific needs.

What is the most efficient hydraulic pump. please click topkitparts see more