Hydraulic pumps are essential for a variety of industrial and agricultural applications. They are used to move fluids, gas, and other materials at high pressure. In this article, we will discuss the types of hydraulic pumps and their uses.

Hydraulic pumps are used in a variety of industrial and commercial settings to move fluids. They are typically classified by the pressure they can produce, with high pressure pumps able to produce pressures up to 100,000 psi (6.8 MPa).

Hydraulic pumps are widely used in industries such as mining, construction, and oil and gas exploration. In this article, we will discuss the different types of hydraulic pumps and their uses.

Hydraulic pumps are used in a variety of industries to move liquids, gas, or powders. The type of pump used will depend on the pressure and flow requirements. In this article, we will explore the different types of high pressure hydraulic pumps and their uses.

Types of hydraulic pumps

Hydraulic pumps are used for a variety of purposes, but they can all be classified under one of two categories: low pressure (LP) and high pressure (HP). LP pumps work with a range of pressures between 0.5 and 5 bars, while HP pumps work with pressures up to 30 bars.

There are many different types of LP and HP hydraulic pumps, making it difficult to decide which one is the best for a specific application. To help make this decision, we’ll explore the different types of LP and HP pumps below.

Types of Low Pressure Hydraulic Pumps

The first type of low pressure hydraulic pump is the vane pump. Vane pumps use a series of vanes to move the fluid through the pump. They’re most commonly used in applications where low pressure is required, such as water supply systems or drainage systems.

Another type of LP pump is the axial flow pump. Axial flow pumps use an impeller to move the fluid through the pump. They’re most commonly used in applications where high velocity is required, such as in engines or water turbines.

How is a hydraulic pump used?

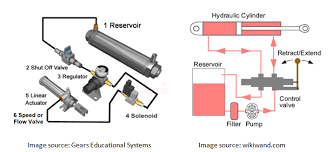

A hydraulic pump is used to create a high pressure stream of water or oil. This high pressure stream is used to move objects or substances.

A hydraulic pump is used to move large amounts of fluid, such as water or oil, at high pressure. This type of pump is often found in industrial and commercial settings, where it is needed to move large amounts of fluid quickly and efficiently.

A hydraulic pump is a machine that uses hydraulic pressure to move fluids or objects. Hydraulic pressure is created when pressurized water, oil, or other fluid is forced through a pipeline.

A hydraulic pump is a machine that uses the power of hydraulics to move fluids. The most common use for a hydraulic pump is in the automotive and construction industries, where they are used to move fluids such as oil, water, and gas.

Advantages and disadvantages of using a hydraulic pump

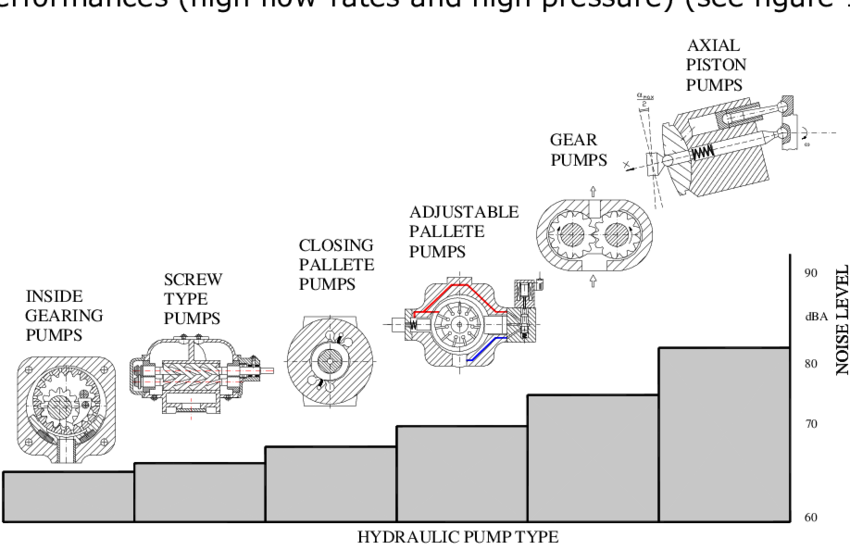

When it comes to choosing the right hydraulic pump for a high pressure application, the advantages and disadvantages of each type must be considered. Here is a look at some of the most common types used for this purpose:

Piston: The piston pump is typically the cheapest option, but it also has the lowest efficiency. It works best when pumping medium to low pressure levels.

Vane Pump: The vane pump is more efficient than the piston pump, but it can also be more expensive. It is best suited for high pressure applications where efficiency is not as important as cost.

Rotary Pump: The rotary pump is the most expensive option, but it also has the highest efficiency. It is best suited for applications where precision and accuracy are essential.

Conclusion

There are many types of hydraulic pumps available on the market, each with their own advantages and disadvantages. We have outlined the key characteristics of the three most common types of high pressure hydraulic pumps here so that you can make an informed decision as to which one is right for your needs.

There are many different types of hydraulic pumps, but the one that is most commonly used for high pressure applications is the centrifugal pump. This type of pump relies on a rotating disc to move fluid through the system, which creates high pressure and makes it possible to apply force quickly and efficiently.

There are a few different types of hydraulic pumps that can be used for high pressure applications. This includes the electric motor driven centrifugal pump, the diesel engine powered rotary pump, and the air compressor driven reciprocating pump. Each of these options has its own advantages and disadvantages, so it is important to choose the right one for your specific application.

Which hydraulic pump is used for high pressure. please click topkitparts see more