If you have hydraulic systems in your business, it’s important to keep them serviced and in good working order. Here are the four things you should do before servicing your hydraulic system:

1. Check the fluid levels and make sure they’re within manufacturer specifications.

2. Clean any debris or foreign objects that may be lodged in the system.

3. Check for leaks and fix them if necessary.

4. Adjust or replace any parts as necessary.

Before servicing the hydraulic systems, it is important to first identify and diagnose any potential issues. By doing this, you can prevent potential damage and ensure that your hydraulic systems are in proper working order.

Inspect the hoses and lines to verify they are not kinked or corroded

Before servicing the hydraulic systems, it is important to inspect the hoses and lines to ensure they are not kinked or corroded. This can prevent potential damage to the hydraulic system and potential safety hazards.

Before servicing the hydraulic systems, it is important to inspect them for any kinks or corrosion. Hydraulic hoses and lines can become kinked or corroded in high-stress areas, causing reduced performance or even failure. By verifying the integrity of the hoses and lines before starting the service, you can avoid potential problems and ensure a smooth repair process.

Before servicing the hydraulic systems, it is important to inspect the hoses and lines for kinked or corroded connections. Checking for kinks and corrosion can help avoid any future problems with the hydraulic system.

Check the condition of the seals on the fittings

A good way to start your inspection of the hydraulic systems is to check the condition of the seals on the fittings. By doing this, you can avoid any potential problems with the system.

One of the most important things to do before servicing hydraulic systems is to

Before servicing the hydraulic systems, it is important to check for leaks. To do this, insert a hose into each fitting and turn it on. If there are any leaks, repairs will need to be made as soon as possible.

check the condition of the seals on the fittings. If there are any leaks, it is important to fix them as soon as possible in order to prevent further damage to the system.

There are a few things to check before servicing hydraulic systems. One is to make sure the seals on the fittings are in good condition. If there are any cracks or tears in the seals, the fluid can escape and create problems.

Check for leaks by inserting a hose into each fitting and turning it on

Before servicing hydraulic systems, first check for leaks by inserting a hose into each fitting and turning it on. If there is a leak, you will need to correct it before proceeding.

The hydraulic system should be pressure tested prior to any servicing. This will ensure the system is working properly and is not leaking. If the hydraulic system is not properly pressure tested, it could result in damage to the system or even injuries.

If there are any leaks, service the hydraulic system as soon as possible to avoid potential damage.

Then look for bubbles coming from the fitting. If there are any leaks, fix them before continuing.

Replace any worn or broken parts

Whenever servicing hydraulic systems, it is important to replace any worn or broken parts first. This will ensure that the system operates correctly and without issue.

If hydraulic fluid is leaking, it’s important to replace any worn or broken parts as soon as possible in order to avoid further damage. Here are some of the most common hydraulic systems that require service:

1. Hydraulic hoses and lines. Replace any leaky hoses or lines as soon as possible to avoid further damage.

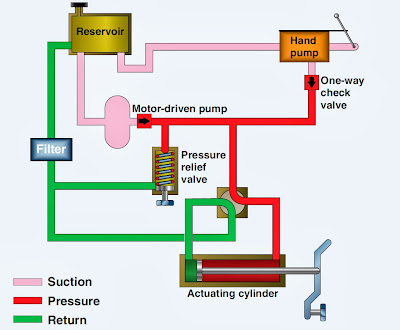

2. Pressure relief valves. If pressure is building up in the system, replace the pressure relief valve to prevent a blowout.

3. Pump seals. Check for leaks and replace any damaged or worn pump seals if necessary.

4. Valves and control valves. Inspect all valves and control valves for wear and tear, replacing any that are damaged or worn.

5. Overhead beams and brackets. Check for loose bolts and replace any that are not fully tightened, especially if the system is prone to vibration or movement.

Verify the hydraulic system is properly pressure tested

Some tips to verify the hydraulic system is properly pressure tested:

1. Verify all hoses are securely connected and flexible.

2. Verify all valves are properly closed.

3. Verify the pump is turned on and operating correctly.

The hydraulic system on your car must be pressure tested before any servicing is carried out. This ensures that the hydraulic systems are functioning properly and there are no leaks. It is important to remember to always test the pressure after any work has been done to the hydraulic system, as leaks can occur at any time.

4. Verify the gauge is reading the correct pressure.

Adjust valves as necessary

Before servicing hydraulic systems, it is important to adjust valves as necessary. By doing this, the hydraulic system will operate at its optimum level and be less likely to malfunction. To adjust valves:

-Locate the valve that needs to be adjusted and identify its type (one way or two way).

-Open the valve fully by turning it counterclockwise with a wrench. Be sure not to overtighten the valve.

-Close the valve by turning it clockwise until it seats in its stop.

-Measure the flow rate at the valve using a gage or flow meter. Note the reading and write it down for future reference.

-If the flow rate is low, turn the valve more clockwise to increase flow; if the flow rate is high, turn the valve less clockwise to decrease flow.

Prepare the system for service

Before servicing any hydraulic system, it is important to make sure that the system is properly prepared. This includes checking fluid levels, ensuring that all hoses and lines are properly connected and secured, and clearing any debris or blockages from the systems. Once the system is ready for service, follow these steps:

1. Check fluid levels: First, check the fluid levels in all hydraulic systems. Make sure that the fluids are at a level that will allow the system to operate smoothly. If there are any problems with the fluids, contact your supplier or mechanic for help.

2. Connect hoses and lines: Next, connect all of the hoses and lines to their corresponding ports on the system. Make sure that each line is connected securely and without leaks.

3. Clear debris: Finally, clear any debris or blockages from the system using a brush or vacuum cleaner. Make sure to wear protective gear if necessary.

Which is the first thing to do before servicing the hydraulic systems. please click topkitparts see more