Hydraulic motors are widely used in various industrial applications for their high speed and low torque characteristics. But, as with all mechanical devices, there is a trade-off between speed and torque. In this article, we will explore the two main factors that determine the speed of a hydraulic motor – pressure and RPM.

Pressure

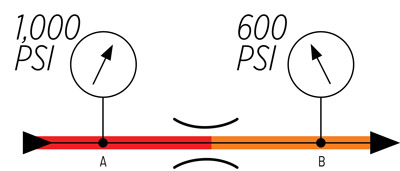

One main factor that affects the speed of a hydraulic motor is the pressure that is applied to the piston. The higher the pressure, the faster the motor will run. However, higher pressures can also cause damage to the motor and its components. Therefore, it is important to maintain a proper balance between pressure and speed in order to avoid any adverse effects.

RPM

Another major factor that affects the speed of a hydraulic motor is its RPM. As mentioned before, higher RPMs can lead to faster speeds, but they can also cause more wear and tear on the machine. It is important to find a good balance between RPM and pressure in order to achieve optimum performance.

What is a hydraulic motor?

A hydraulic motor is an electric motor that uses hydraulic pressure to create rotational motion. Hydraulic motors are used in a variety of applications, from forklifts to car door openers. They’re also popular in commercial fishing, where they’re used to power trap nets and hauls.

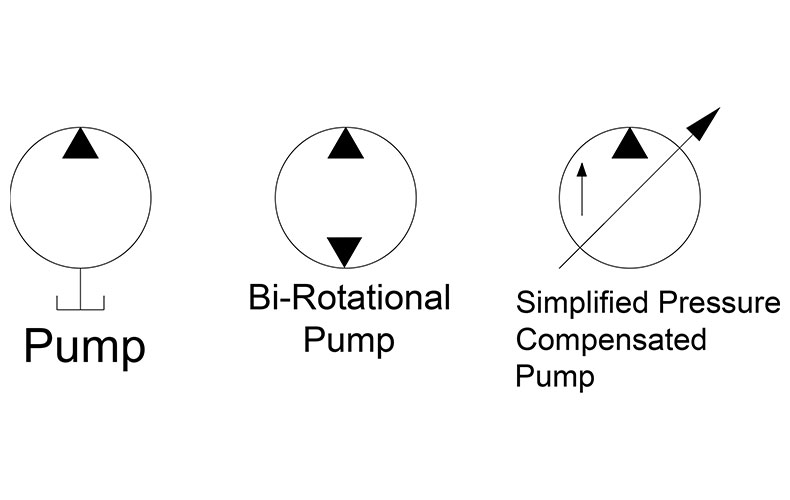

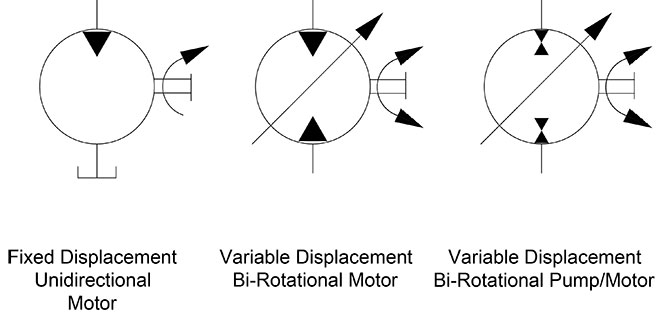

How do hydraulic motors work?

A hydraulic motor works by using the pressure of fluid flow to rotate a shaft. The fluid is typically water or oil, and it’s forced through a nozzle at the top of the motor. The nozzle creates a high level of pressure inside the motor, which causes the shaft to rotate.

What are some benefits of using a hydraulic motor?

One advantage of using a hydraulic motor is that it’s environmentally friendly. Because hydraulic motors use water or oil as the fluid, they don’t produce emissions like traditional electric motors do. Additionally, they’re often more efficient than electric motors when it comes to generating power. This means that they can be used to power larger devices without consuming as much energy.

What are some drawbacks of using a hydraulic motor?

One drawback of using a hydraulic motor is that they require

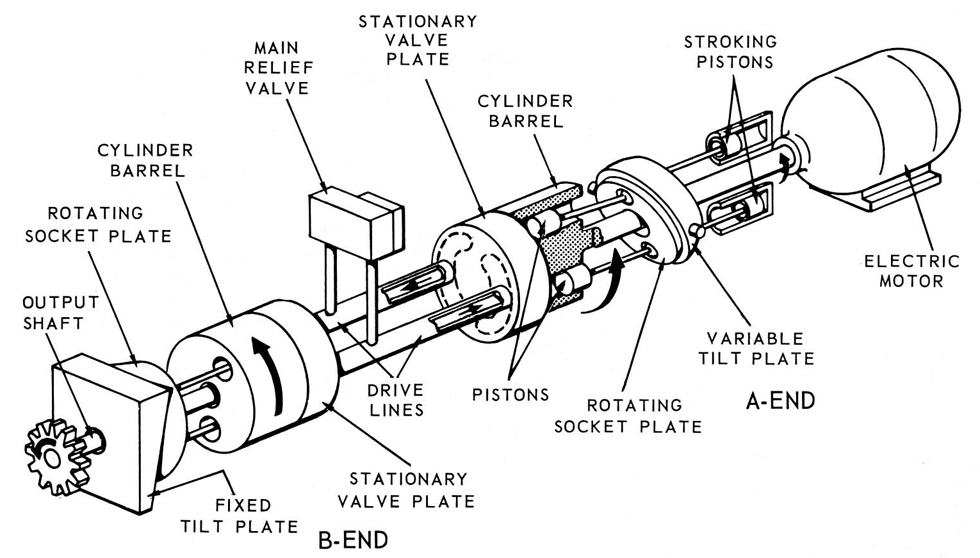

How does a hydraulic motor work?

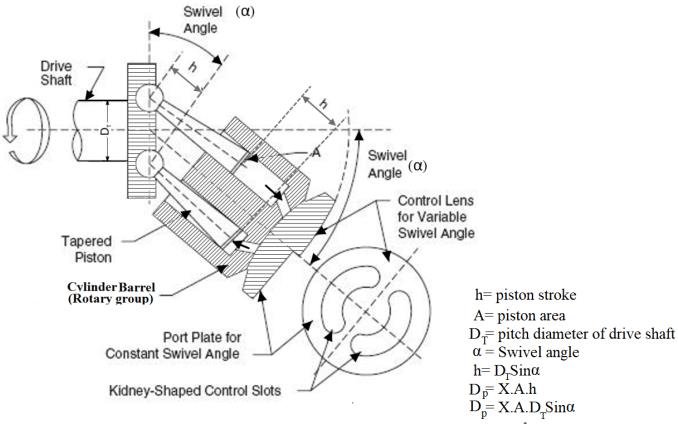

When you use a hydraulic motor, you are using hydraulic pressure to move an object. A hydraulic motor is made up of two parts: the pistons and the cylinders. The pistons are movable and the cylinders are stationary. The pistons are connected to the cylinders by a series of rods. When you apply hydraulic pressure to the pistons, it causes them to push against the cylinders. This creates a force that moves the cylinder and the object it is attached to. The speed of a hydraulic motor is determined by how much pressure you apply to the pistons and how many cylinders there are.

The Hydraulic Motor Speed Theory

The speed of a hydraulic motor is determined by the amount of pressure that is applied to the piston. The higher the pressure, the faster the piston will move.

The speed of a hydraulic motor is also affected by the size and shape of the piston. Pistons with a larger diameter move faster than those with a smaller diameter.

The speed of a hydraulic motor also depends on the type of fluid that is used to power the piston. Fluids with a low viscosity move faster than those with a high viscosity.

What is the speed of a hydraulic motor?

The speed of a hydraulic motor is determined by the size of the plunger and the pressure applied to it. The smaller the plunger, the higher the pressure needed to move it and the faster the motor will operate.

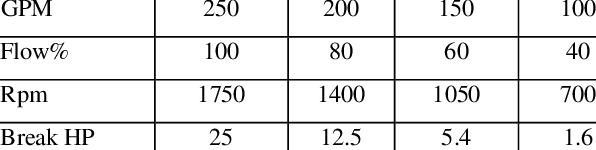

Typically, hydraulic motors operate at a speed of around 1500 rpm.

How fast can a hydraulic motor go?

A hydraulic motor can go up to 6,000 RPM. The higher the RPM, the faster the motor will move.

Equation to Determine the Speed of a Hydraulic Motor

The equation to determine the speed of a hydraulic motor is P=V*F. This equation states that the speed of the hydraulic motor is proportional to the square of the power (P) and inversely proportional to the radius of the piston (V).

To find the power required by a hydraulic motor, divide the desired output by the speed of the motor.

For example, if you want to move a weight that is 10 pounds and the motor is going at a speed of 20 miles per hour, the power required to move the weight would be 100/20 or 5 watts.

If you want to move a weight that is 100 pounds and the motor is going at a speed of 20 miles per hour, the power required to move the weight would be 1000/20 or 200 watts.

To find the radius of the piston, divide the desired output by P. For example, if you want to move a weight that is 10 pounds and the motor is going at a speed of 20 miles per hour, the radius of the piston would be 0.2 or 2 inches.

How do you change the speed of a hydraulic motor?

There are a few ways to change the speed of a hydraulic motor. One way is to use a governor, which is a device that controls the speed of the motor. Another way is to adjust the valve timing.

Some hydraulic motors have a built-in speed regulator. This is a device that allows you to change the speed of the motor without having to adjust the valve timing.

If you don’t have a governor or speed regulator, you can adjust the valve timing to change the speed of the motor.

To adjust the valve timing, you’ll need to remove the cover of the motor and access the valves. You’ll also need a red pen or a marker to label the valves so you know which is which.

To change the speed of the motor, you’ll need to turn one of the valves (usually the leftmost valve) clockwise or counterclockwise. The closer the number on the valve is to 12 (the number of revolutions per minute), the faster the motor will run.

Conclusion

The speed of a hydraulic motor is determined by three factors: the pressure in the cylinder, the length of stroke, and the viscosity of fluid. The higher the pressure, the faster the motor will run; likewise, a longer stroke will increase engine speed. Finally, fluids with high viscosities resist flow, which affects engine speed.

What determines the speed of a hydraulic motor,please click topkitparts see more