Hydraulic pumps are an essential piece of equipment for a variety of purposes, from moving water to pumping out oil spills. In this article, we’ll explore the cost of a hydraulic pump and figure out what factors go into determining its price.

What is a hydraulic pump?

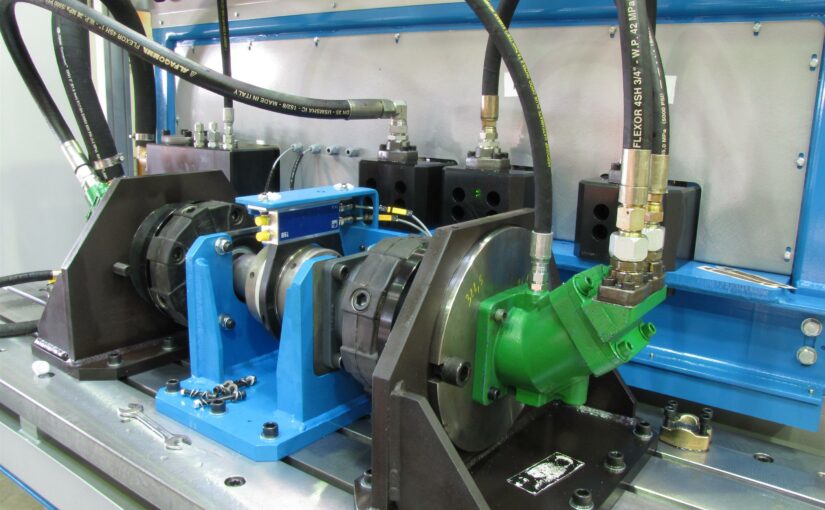

A hydraulic pump is a machine that uses pressurized fluid to move objects or substances. The fluid can be water, oil, or another type of liquid. The pressure from the fluid causes the object or substance to move.

A hydraulic pump is made up of many parts. The engine drives the gears that create the pressure in the system. The discharge line sends the pressure out to the object or substance that needs to be moved. There are also valves that allow the pressure to flow in and out of the system as needed.

The size and type of hydraulic pump depends on what it is being used for. A small pump might be used to power a toy car while a large pump can be used to power a boat or an industrial machine.

The different types of hydraulic pumps

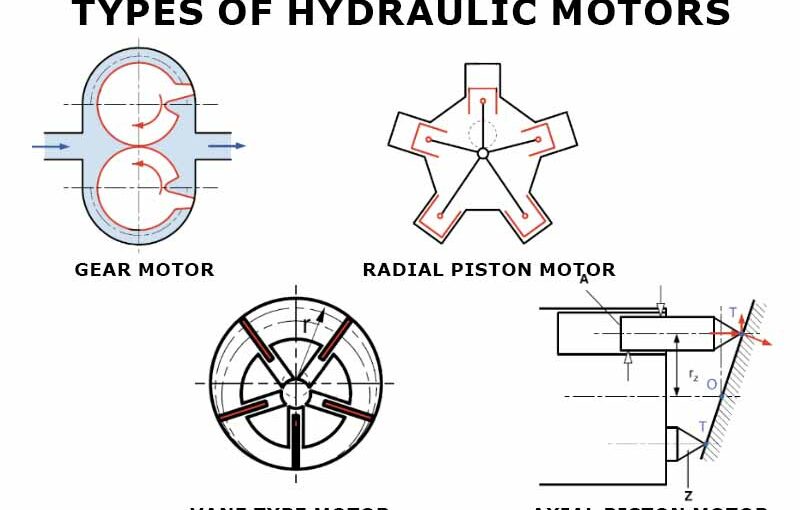

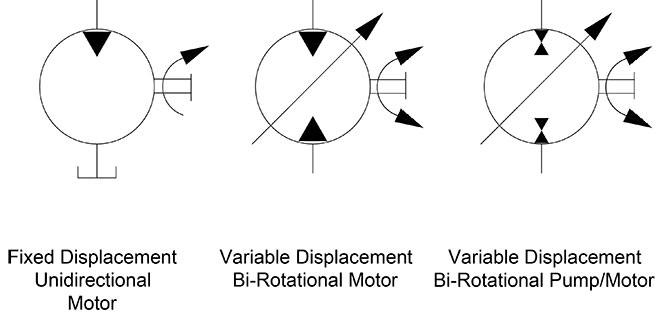

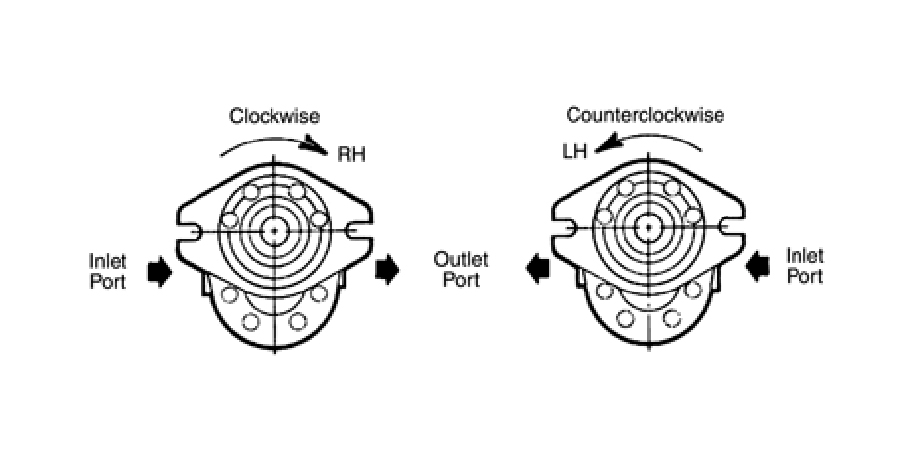

There are a few different types of hydraulic pumps, each with its own advantages and disadvantages. Here’s a quick overview of the most common types:

Pump type Advantages Disadvantages Reciprocating

This pump is typically used in industrial applications and is known for its durability and low noise levels. It has multiple pistons that move back and forth, which creates a pressurized fluid flow. The downside is that this type of pump is less efficient than other types and can require more power to operate. Rotary

A rotary pump is similar to a reciprocating pump in that it uses pistons to move the fluid, but the rotation speeds are much higher, which makes it more efficient. This type of pump is also less noisy than a reciprocating pump and can be used in smaller applications. However, rotary pumps can be more expensive due to their high efficiency and durability. Vane

A vane pump is similar to a rotary pump in that it uses pistons to move the fluid, but the vane motion creates a force that pushes the fluid through the pump. This type of pump is less expensive than a rotary or reciprocating pump and is often used in lower-power applications.

Which pump is best for your application?

There’s no one-size-fits-all answer to this question, as the best pump type for a specific application depends on the specific requirements of that application. However, some factors to consider when choosing a pump include power requirements, noise levels, and efficiency.

Advantages and Disadvantages of a Hydraulic Pump

The cost of a hydraulic pump is generally much less than the cost of an electric pump, which makes it an attractive option for smaller applications. Additionally, hydraulic pumps are both reliable and efficient, making them a popular choice for high-volume applications. However, they can be more expensive to maintain than electric pumps, and they require careful monitoring to avoid damage.

Hydraulic pumps are also less versatile than electric pumps, which may limit their ability to perform certain tasks. Additionally, they can be more difficult to move and install, making them less suitable for applications that require flexibility.

How to Choose a Hydraulic Pump

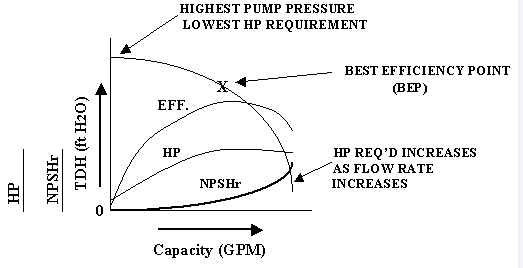

When choosing a hydraulic pump, you’ll need to consider a few factors. The first is the type of application for which the pump will be used. For example, a pump designed for use in water or oil wells would require different features than one designed for use in a construction site. Second, you’ll need to determine the horsepower required by the application. Finally, you’ll need to consider the price of the pump.

If you’re looking for a pump that can be used in a variety of applications, consider looking for a modular pump. Modular pumps are designed to be interchangeable, so you can change the horsepower and type of application without having to buy a new pump.

When it comes to horsepower, you’ll need to decide on the required power. For example, if you’re looking for a pump that can be used in an oil well, you’ll need a pump with a higher horsepower than if you’re using it in water.

Finally, when it comes to price, remember that the price of a hydraulic pump will vary depending on the model and the features it includes. However, most pumps will cost between $1,000 and $5,000.

What are the Factors that affect the Cost of a Pump?

There are many factors that affect the cost of a hydraulic pump. The most important factors are the type of pump, the location of the pump, and the type of fluid being pumped. Other factors that can affect the cost of a pump include the quality of the components used in the pump, the speed at which the pump operates, and the labor required to install and operate the pump.

Where to Buy a Hydraulic Pump

When looking to buy a hydraulic pump, it is important to know the cost of each option. The table below will give an overview of the different types of hydraulic pumps and their corresponding prices.

Type of Hydraulic Pump Price (USD)

Portable hydraulic pump $2,000-$4,000

Industrial hydraulic pump $10,000-$50,000

Pumping station $50,000-$250,000

When should you buy a hydraulic pump?

The cost of a hydraulic pump can vary depending on the model and the brand. Generally, the more functions a pump has, the more expensive it will be. Additionally, some features, such as automatic pressure control or remote operation, can add to the price.

Conclusion

If you’re looking to buy a hydraulic pump, it’s important to understand the different types and the costs associated with each one. By understanding the cost of a particular type of hydraulic pump, you’ll be able to make an informed decision about what kind of pump is best for your needs.

What is the cost of a hydraulic pump, please click topkitparts see more