Vickers Pumps is proud to announce the release of our new VMQ Series line of Centrifugal Pumps. The Vickers VMQ Series features a rugged cast iron construction with a corrosion resistant coating. The new design incorporates a modular design that allows for easy field repair and maintenance with replaceable parts.

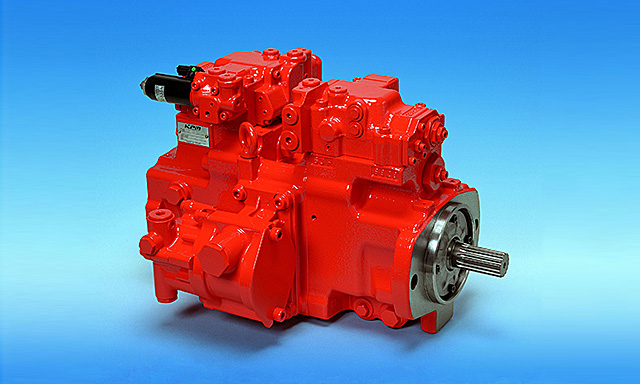

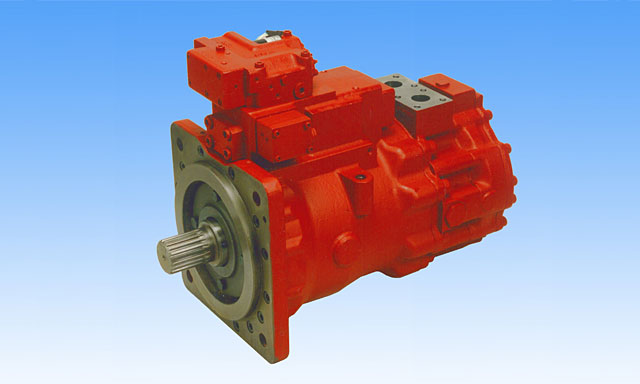

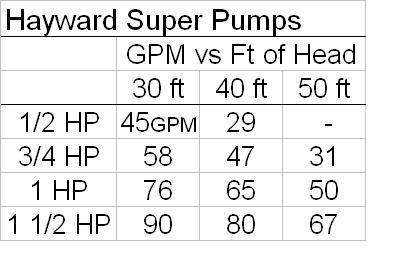

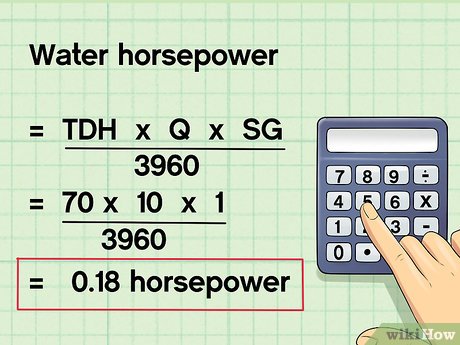

The new Vickers VMQ Series centrifugal pumps are available in four sizes ranging from 0.5 HP up to 10 HP and can be configured with either mechanical or electric control options. The pump body is constructed from cast iron and is coated with a high quality epoxy paint to prevent corrosion and abrasion damage during operation. Each model comes equipped with an adjustable CNC machined impeller assembly that allows operators to fine tune flow rate settings based on their specific applications.

Vickers VMQ Series vane pumps are versatile solutions for use in general industrial applications.

Vickers VMQ Series vane pumps are versatile solutions for use in general industrial applications. They have been designed to meet the requirements of a wide range of pumping applications, including corrosive and abrasive liquids, chemicals and food products.

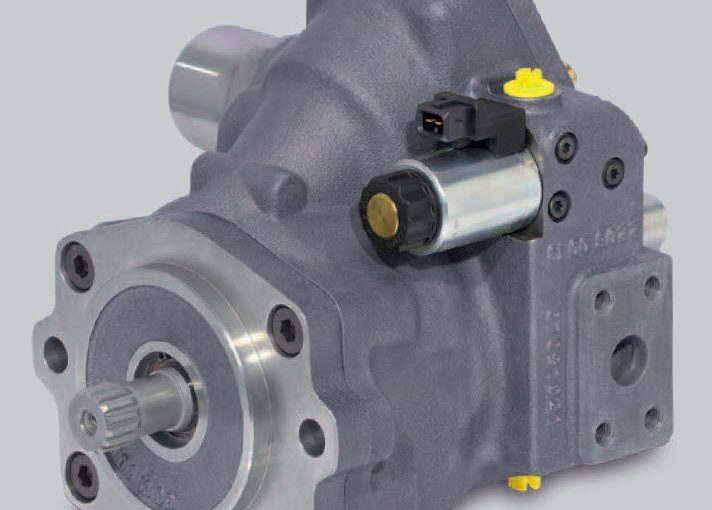

The VMQ Series has been designed with the latest Vickers technology. This has resulted in a product that is compact, lightweight, powerful and easy to maintain.

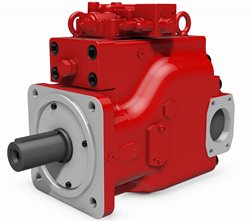

The VMQ Series features a robust construction with a high specification cast iron casing and volute. The design incorporates an aluminium alloy impeller which provides excellent shaft sealing characteristics when pumping liquids containing abrasives. The impeller is manufactured from a corrosion resistant material and is heat treated for maximum strength and durability.

The Vickers VMQ Series is suitable for use in many different industries including food processing, chemical manufacturing, oil refining, power generation and water treatment plants where corrosive liquids are present or where aggressive chemicals may be encountered.

Integral check valve prevents reverse flow and increases system response time.

The VMQ series of positive displacement pumps are designed for use in positive displacement applications. The pump is available in a wide range of sizes and flow capacities to suit most applications.

The pump has a cast iron body with an integral check valve to prevent reverse flow. This eliminates the need for additional check valves and reduces the number of parts required to complete the system. It also reduces the amount of maintenance required because there are fewer parts that can fail.

The design of this pump provides quick response times and high durability. The pump is suitable for applications where quick response times are required, such as food processing equipment, chemical processing equipment, water treatment plants and livestock feed systems.

External bypass valve minimizes pressure spikes, lowers peak discharge pressure, and extends system component life.

Vickers VMQ Series vane pumps are the most economical choice for the widest range of applications. Vickers VMQ Series vane pumps are available for water, wastewater, and many other fluids. VMQ Series vane pumps provide excellent performance at low pressure drop and high flow rates. These highly reliable pumps feature a direct drive design, external bypass valve minimizes pressure spikes, lowers peak discharge pressure, and extends system component life.

Flexible bearing retainer makes assembly simple and reduces maintenance costs.

Vickers VMQ Series vane pumps are designed for use in many applications where reliability, efficiency and low maintenance are important. They feature a single seal design and use a flexible bearing retainer that makes assembly simple and reduces maintenance costs.

The Vickers VMQ Series vane pump family includes single-stage, double-stage, multistage and turbine models. These units are available in either oil-free or lube-free configurations. They can be used in clean or dirty environments, as well as in water or steam applications.

The Vickers VMQ Series pumps feature an inverted volute design that provides a compact package while maximizing flow capacity. Their unique impeller design maximizes efficiency while reducing power consumption by up to 20%. The results are lower operating costs and extended pump life when compared to conventional centrifugal pumps.

Standard SAE A 2-bolt flange connection provides added strength when compared to SAE B 4-bolt connections.

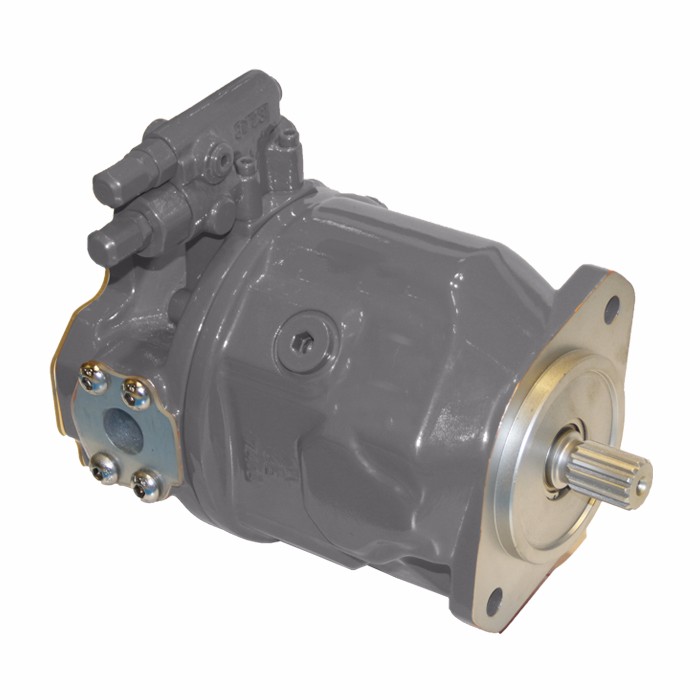

The Vickers VMQ Series vane pumps are high-performance, high-pressure positive displacement reciprocating piston pumps with a rugged cast iron body and frame. The pumps are available in a variety of configurations, including single or double acting models with suction, discharge and pressure ports on any side at any angle. The rugged construction of these pumps makes them suitable for use in a wide range of applications such as industrial pressure washers, irrigation systems and other applications requiring high pressures at low volumes.

The Vickers VMQ Series vane pumps are designed for extreme conditions, including severe shock loads, abrasive fluids and high temperatures. They feature an internal maintenance-free mechanical seal and corrosion resistant stainless steel shafts with antirotation bearings for long life. They also have an option for a C-face flange connection design that provides added strength when compared to SAE B 4-bolt connections.

Vickers VMQ Series vane pumps can be easily modified with optional mounting flanges or shafts to fit your specific application needs.

The Vickers VMQ Series vane pump is a compact, high-performance hydraulic pump ideal for use in applications such as industrial, agricultural and automotive. These pumps feature an integrated motor and gearbox that can be easily modified with optional mounting flanges or shafts to fit your specific application needs.

Vickers VMQ Series vane pumps are available in both single-acting and double-acting configurations. The double-acting model features an externally accessible reversing valve that allows the pump to be used with either direction of flow.

The Vickers VMQ Series vane pumps are designed to handle large volumes of fluid at high pressure while minimizing power consumption and space requirements. They are ideally suited for applications requiring high pressure capabilities with minimal horsepower requirements or those where portability is important due to the small size of the unit.

Vickers VMQ Series pumps have many design features that make them a good choice for an array of industrial applications.

The Vickers VMQ Series vane pumps are designed for use in high temperature environments. They are available as oil-lubricated or water-cooled models and can handle a wide range of viscous fluids, including hydrocarbons, synthetic oils, greases and coolants. The pumps are also suitable for handling non-Newtonian fluids, such as suspensions or emulsions.

These single-stage centrifugal pumps have a high starting torque and can handle large flows at low pressure drops. Their rugged construction makes them ideal for use on truck and trailer mounted fire fighting systems where they are exposed to rough handling during transport and storage.

The VMQ Series optimises energy consumption and environmental impact without compromising on performance. The VMQ pumps are also space-saving, thanks to their compact design, making them an ideal choice for boiler water pumping systems.