Pumps are crucial pieces of machinery in water treatment plants, responsible for moving water from one part of the plant to another. In this article, we’ll be looking at the different types of pumps and their respective efficiencies, so that you can make the most informed decision when it comes to pump design.

What is a pump?

Pumps are machines that use a flow of fluid through a pipe to move something from one place to another. A pump can be used for many purposes, including moving water, oil, gas and other fluids. There are many different types of pumps, but all of them have one thing in common: they’re very efficient machines that can move a lot of fluid quickly.

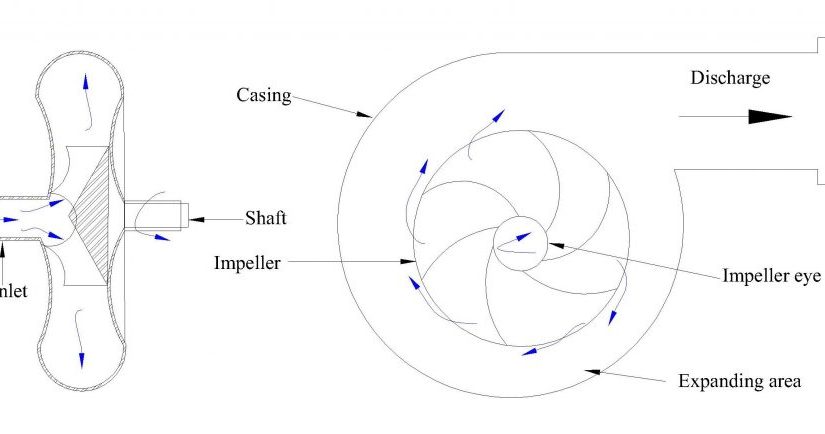

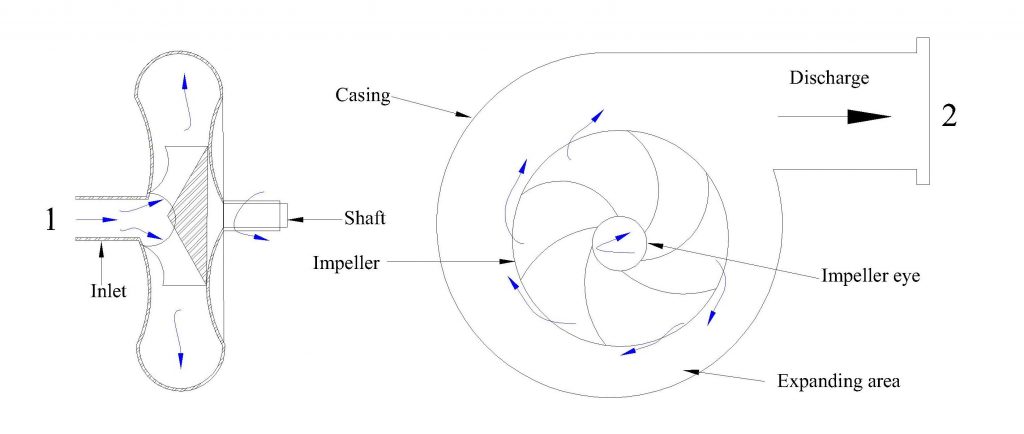

One of the most efficient pump designs is the centrifugal pump. This type of pump uses rotational motion to create a force that pushes or pulls objects through a fluid. Centrifugal pumps are used to move a lot of liquids and gases around, and they’re especially good at moving liquids because they can do so quickly and without much noise.

The downside to centrifugal pumps is that they’re not the best choice for moving solids. This is because they don’t have enough torque to push solid objects through the fluid, so they often require additional equipment to help them move things like soil or rocks.

But despite their limitations, centrifugal pumps are still one of the most efficient pump designs available. They’re perfect for applications that need quick movement of liquid or gas, and they’re

Overview of Pump Design

When it comes to pumps, there are a variety of different designs available with different efficiencies. In this article, we will be discussing the most efficient pump design possible and its benefits.

The most efficient pump design is a centrifugal pump. A centrifugal pump is a type of pump that uses the force of rotation to move fluid through the device. Centrifugal pumps are generally more efficient than other types of pumps because they can move a greater amount of fluid with each turn of the impeller.

One benefit of using a centrifugal pump is that it can be used in applications where space is at a premium. Centrifugal pumps are also relatively easy to maintain and operate, making them a good choice for industrial applications.

Comparison of Various Pump Designs

There are a variety of pump designs available on the market, each with its own set of advantages and disadvantages. In this article, we will compare the most efficient pump designs available and help you choose the best one for your specific application.

The first thing to consider when choosing a pump design is the horsepower required. Different applications will require different horsepower levels, so it is important to identify this upfront. Higher horsepower pumps are generally more efficient, but they can also be more expensive. If you don’t need the highest possible efficiency level, then a lower-powered pump may be more affordable and still achieve the desired results.

Next, you will want to choose the type of fluid being pumped. Each type of fluid requires a different type of pump design in order to efficiently move the fluid through the system. For example, oil requires a centrifugal pump while water requires a piston pump. Again, identifying the type of fluid being pumped is key to selecting the correct pump design.

After identifying the requirements of the pump and the type of fluid being pumped, you will need to select a pump manufacturer and determine which model(s) fit your needs best. There are many different types of pumps available

Why Is the Pump Design Important?

When you are looking to buy a pump, there are a few things you need to take into account. The pump design is one of them. When you choose the right pump, it will save you time and money in the long run. Here are three reasons why pump design is so important:

1. Efficiency: When you have a well-designed pump, it will work more efficiently. This means that it will use less energy and produce less waste. It is important to choose a pump that is matched to your needs, as this will save you money in the long run.

2. Durability: A well-made pump will last longer and be more resistant to wear and tear. This means that it will not need to be replaced as often, which can save you money in the long term.

3. Customization: When you have a well-designed pump, you can tailor it to your specific needs. This means that it can be used for different applications without having to change the design. This can save you time and money in the long run.

How Pump Design Affects Efficiency

When pump designers are trying to optimize their designs, they must take into account many factors. Some of these factors include the type of fluid being pumped, the size and shape of the pump, and the desired output. However, one factor that often gets overlooked is pump efficiency.

Pump efficiency is a measure of how much work a pump can do per unit of input power. It can be thought of as the percentage of the maximum possible output that can be achieved with a given amount of power.

There are a number of factors that affect pump efficiency, including the design of the pump itself, the geometry of the impeller and flow passages, and the discharge head characteristics. Each of these factors can have a significant impact on how much work a pump can do per unit of power.

Some common measures of pump efficiency include volumetric (or static) efficiency, specific impulse, and rotational speed. Each of these measures has its own advantages and disadvantages, but all three are useful when trying to optimize an engine or pump design.

Factors that Affect Pump Efficiency

Pump efficiency is a critical factor when selecting a pump for a given application. Factors that affect pump efficiency include the type of fluid being pumped, the pressure and flow rate of the fluid, and the design of the pump.

When selecting a pump for a given application, it is important to consider the type of fluid being pumped and the pressure and flow rate of the fluid. For example, a centrifugal pump is typically more efficient when pumping viscous fluids, such as oil or grease, than when pumping less viscous fluids, such as water. Conversely, an impeller-type pump is typically more efficient when pumping water at high pressures than when pumping lower pressures.

The design of the pump also affects pump efficiency. For example, a double-suction spiral elbow pump is more efficient than a single suction spiral elbow pump when lifting heavy objects because it requires less energy to lift the object due to its greater efficiencies.

Factors to consider when choosing the most efficient pump design

There are many factors to consider when choosing the most efficient pump design, including: Horsepower required, flow rate required, number of pumps required, and pump type. Here are three tips to help you choose the right pump for your needs:

1. Decide on the horsepower required. The higher the horsepower requirement, the more powerful the pump need to be. For example, a pump that needs 2 horsepower will require twice as much energy as a 1 horsepower pump.

2. Determine the flow rate required. The higher the flow rate requirement, the more pumps will be needed to achieve that rate of flow. For example, if a product needs to be pumped at a rate of 1000 gallons per minute, then four pumps will be needed.

3. Determine the number of pumps required. The more pumps that are needed, the more expensive the pump will be. For example, a pump with a capacity of 500 gallons per minute will require two pumps whereas a pump with a capacity of 1000 gallons per minute will require four pumps.

Which is the Most Efficient Pump Design?

There are a few different types of pumps that can be used to move liquids or gas. The most efficient pump design is typically the one that uses the least amount of energy to complete the task. There are a few factors that can affect how much energy a pump requires to complete a task, including the type of pump, the size and shape of the object being pumped, and the pressure involved.

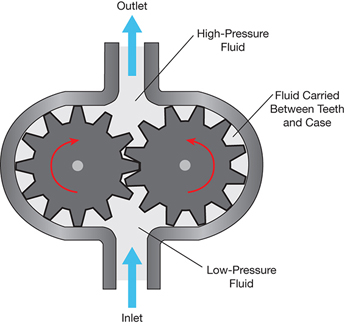

One of the most common types of pumps is the piston pump. These pumps use a cylinder filled with air or gas to push objects through a fluid. Piston pumps are typically less efficient than other types of pumps because they require more energy to move objects through a fluid. Another type of pump that is less efficient is the turbine pump. These pumps use blades on an impeller to create movement in fluids. Turbine pumps are usually more efficient than piston pumps, but they can also be more expensive due to their high cost associated with manufacturing them.

Other factors that can affect how much energy a pump requires to complete a task include the size and shape of the object being pumped, and the pressure involved. Pumps that are designed to move smaller objects or objects at lower pressures may require less energy than those designed for larger objects

Conclusion

There are many different pump design options available on the market today, and it can be hard to decide which option is best for you. Our experts have put together this guide to help you choose the most efficient pump design for your specific needs. By understanding what factors are important to you, you will be able to find the perfect pump for your unique goals.

What is the most efficient pump design,please click topkitparts see more