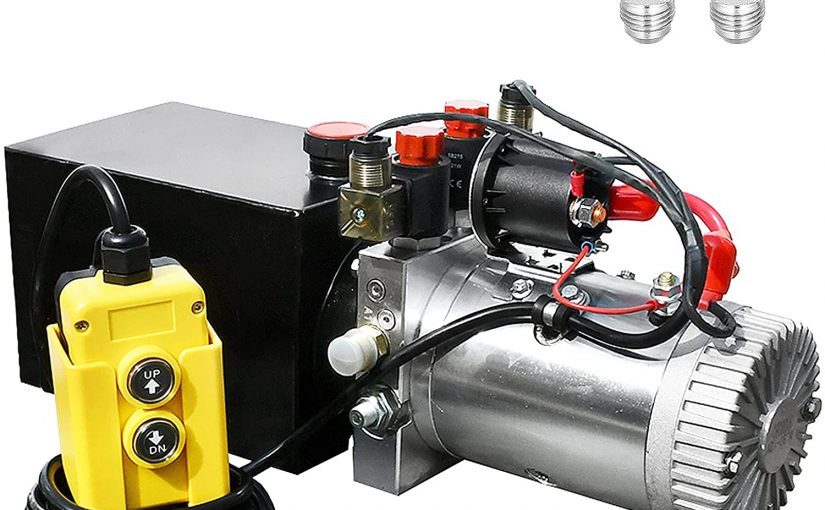

Your hydraulic pump is one of the most important pieces of equipment on your property. It’s responsible for moving large amounts of water, oil or gas where you want it to go. So it’s always important to make sure that your pump is in good condition and operating at its best. In this article, we’ll walk you through some simple steps you can take to increase the pressure on your hydraulic pump.

What is a hydraulic pump?

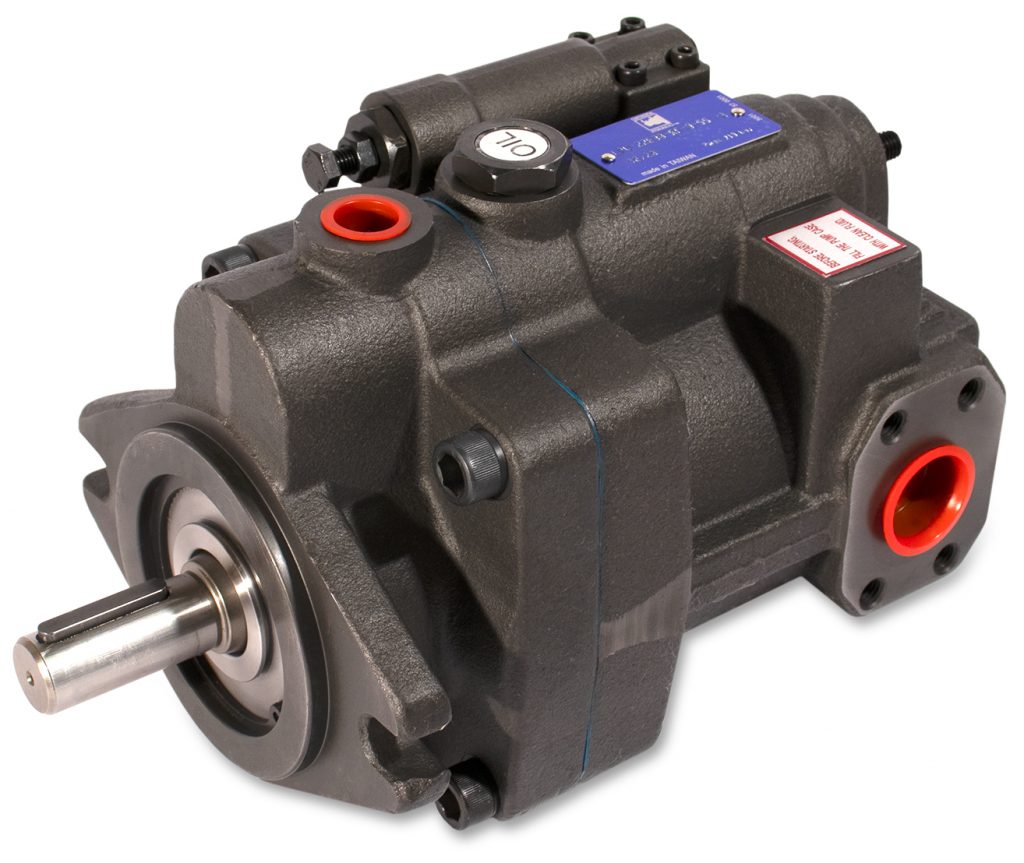

A hydraulic pump is a device that uses pressurized fluid to move objects. It works by moving the fluid through a series of pistons and chambers, which creates a force that can be used to move objects.

Hydraulic pumps are used in a variety of applications, including manufacturing, transportation, and agriculture. They are also used to create waterfalls and other artificial water features.

How do hydraulic pumps work?

One of the most important functions of a hydraulic pump is to create pressure. This pressure is used to move fluids, gases and other objects through pipes or other channels.

There are a number of ways to increase the pressure on a hydraulic pump. One way is to use a larger motor. Another is to use a higher pressure fluid. Lastly, you can use a higher flow rate.

What are the causes of high/low pressure in a hydraulic pump?

There are a few causes of high or low pressure in a hydraulic pump, including incorrect fluid level, worn seals, and blocked passages. Here are some tips to increase pressure in your hydraulic system:

1) Check the fluid level. Make sure there is enough oil or water circulating through the system to keep the pressure up. If there is not enough fluid, add more until the desired pressure is reached.

2) Inspect seals and passages for wear or blockages. If there is damage, it will cause the system to lose pressure. Repair or replace any seals that need it.

3) Check for air bubbles in the system. Air bubbles can form when fluids mix and cause the pressure to drop. Use a bubble detector to check for these bubbles and remove them if found.

What happens if the pressure on my hydraulic pump is too low?

If the pressure on your hydraulic pump is low, it can cause problems. Low pressure can cause the pump to overheat, which can damage the pump or even cause it to fail. There are a few things you can do to increase the pressure on your hydraulic pump.

One option is to add more oil to the hydraulic pump. Adding oil will help increase the pressure and keep your machine running smoothly.

Another option is to increase the size of the hydraulic pump. By increasing the size of the pump, you can increase the amount of pressure that it can generate. This will help ensure that your machine runs smoothly and without issues.

How do I test my pump for low pressure?

Testing your pump for low pressure is an important step in maintaining its functionality. There are a few ways to test your pump for low pressure: using a gauge, visual inspection, and testing procedures.

To test your pump for low pressure using a gauge, connect the gauge to the discharge port of the pump and turn on the power. The reading on the gauge should be within the desired range. If it is not, there may be a problem with the pump or with the system in which it is being used.

If visual inspection does not reveal any signs of a problem with your pump, you can proceed to testing procedures. Testing procedures include running the pump at full speed for a set amount of time, checking for leaks, and subjecting the pump to extreme cold or heat.

When is there too much pressure in a hydraulic pump?

When hydraulic pressure is too high, it can cause damage to the pump and system. There are a few ways to determine when hydraulic pressure is too high:

-Check the system pressure gauge. If the gauge reads higher than the system pressure limit, then the pressure is too high.

-Check the pump output rating. If the pump output rating is less than the system’s required output, then the pressure is too high.

-Measure stroke volume (SV) at maximum load and compare it to SV during idle. If SV exceeds idle by more than 50%, then the pressure may be too high.

How do I troubleshoot a hydraulic system?

One of the most common problems with hydraulic systems is a low pressure. This can be caused by a variety of reasons, but the most common is a broken or clogged pump. To troubleshoot a low pressure hydraulic system, you will need to identify the problem and find a solution. Here are four tips to help you do just that:

1. Check the Pump: The first step in troubleshooting a low pressure system is checking the pump. If the pump is working properly, then the next step is to check for debris or blockages. If the pump is not working, then you will need to replace it.

2. Test the System: Once you have determined that the pump is working, test the system by applying pressure to one end of the line. If there is low pressure at that end, then it likely means that there is an issue with either the line or the pump itself.

3. Check for Line Problems: If there are no faults with the pump or line, then it may be necessary to check for blockages in either of them. Use a scope or other diagnostic equipment to identify any obstructions. If there are any, remove them and try again.

Conclusion

If you’re having trouble increasing the pressure on your hydraulic pump, it might be time to consult with a professional. While most problems can be fixed with a little tinkering, some issues may require the assistance of an expert in order to get them resolved. Remember to always keep your equipment properly maintained and consult with your manufacturer if you encounter any difficulties.

How do I increase the pressure on my hydraulic pump,please click topkitparts see more