Hydraulic pressure is the force that presses down on a liquid in a pipe or tube. It’s measured in pounds per square inch (psi), and it’s what allows us to operate hydraulic systems, such as pumps and valves.

Normal hydraulic pressure is about 30 psi.

Some systems may have higher or lower pressures, depending on the type of hydraulic system and the application.

For example, a high-pressure hydraulic system may be used in manufacturing to press down on parts to move them or create a seal. A hydraulic system used to irrigate plants may have lower pressure, because the liquids are flowing out rather than being pressed in.

Keep in mind that pressure can also be increased or decreased with the use of a pump, depending on the direction of the flow.

If the pressure in a hydraulic system gets too high, it can cause damage to equipment or even rupture the pipe. If the pressure in a hydraulic system gets too low, it can cause the liquid to start leaking out of the system.

What is hydraulic pressure?

Hydraulic pressure is the amount of force applied to a liquid or gas by a pump. It is measured in pounds per square inch (PSI). Normal hydraulic pressure is between 3000 and 4000 psi.

Hydraulic pressure is used in a variety of applications, such as irrigation, mining, oil drilling, and manufacturing.

Why is Normal Hydraulic Pressure Important?

Normal hydraulic pressure is one of the most important factors affecting the performance of your hydraulic machinery. It ensures that the oil in the system is able to flow freely and push the machinery forward. It’s also important for preventing cavitation, which can damage equipment and result in decreased performance.

In order to maintain normal hydraulic pressure, you need to make sure that your systems are operating at their optimum level. By understanding what normal pressure is and how it affects your machinery, you can keep your equipment running smoothly and ensure maximum performance.

What is Cavitation?

Cavitation is a phenomenon that can damage your equipment and result in decreased performance. Cavitation occurs when the oil in your hydraulic system starts to boil and form bubbles. These bubbles are then forced to move quickly through the system, which causes them to become extremely small. This tiny size makes them extremely fragile, which can eventually lead to their destruction.

Cavitation can happen in any hydraulic system, but it’s most often seen in systems that use high pressure (above 100 pounds per square inch [psi]). This high pressure causes the oil to boil quickly and form bubbles. If your machinery relies on normal hydraulic pressure to operate, cavitation can cause major damage.

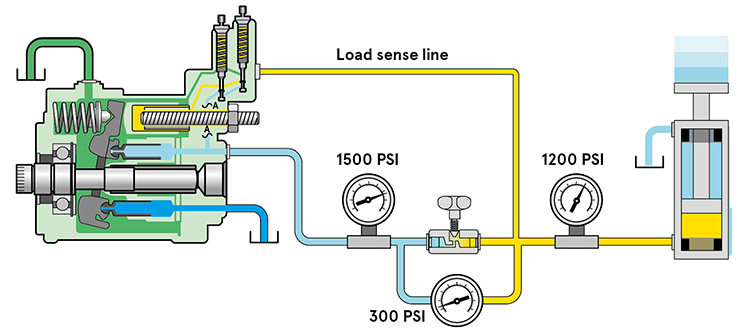

How hydraulic pressure is measured

Hydraulic pressure is the force exerted by a liquid or gas under the action of a pump. It is measured in kilopascals (kPa), abbreviated as “K”. The higher the pressure, the greater the flow of liquid or gas.

Hydraulic pressure is measured at the inlet to the pump and at the outlet of the pump.

Hydraulic pressure is expressed in absolute terms or in terms of gauge pressure.

Absolute hydraulic pressure is the pressure measured at the inlet to the pump, regardless of the pressure in the system.

Gauge pressure is the pressure measured at the outlet of the pump, as measured against a standard atmospheric pressure of 1 atm (101.3 kPa).

Normal hydraulic pressure

Normal hydraulic pressure is the pressure exerted by a fluid when it flows through a pipe or other tube. It’s measured in pounds per square inch (PSI), and is the standard measurement used in hydraulics. Normal hydraulic pressure is important because it determines how much force a pump can generate, and how quickly the pump can move fluids.

If normal hydraulic pressure is low, the pump will struggle to move fluids at a good rate. This can lead to inefficient operation and possible damage to equipment. Conversely, if normal hydraulic pressure is high, the pump will be able to move fluids at a faster rate, but may also create excessive force and wear on equipment. It’s important to keep normal hydraulic pressure as close as possible to its ideal value so that equipment operates smoothly and efficiently.

What causes high (hyper) and low (hypo) pressure?

Hydraulic pressure is measured in pounds per square inch (psi). Normal pressure is between 10 and 20 psi. High pressure is greater than 30 psi and low pressure is less than 10 psi.

The most common causes of high and low pressure are:

1. Damaged or failing pipes

2. Low flow due to obstruction (such as a clog) in the system

3. Poorly designed or installed pumps

What are the effects of high or low hydraulics?

Hydraulic pressure is a measure of the pressure exerted by liquid or gas in a system. It is measured in units of pounds per square inch (PSI). Normal hydraulic pressure is around 20 PSI. Higher pressures are often found in systems used for industrial purposes, such as oil and gas production, while lower pressures are common in household applications, such as washing machines.

High hydraulic pressures can have negative effects on systems. For example, high hydraulic pressures can cause engine failure or damage hydraulic systems. Low hydraulic pressures can also have negative effects on systems. For example, low hydraulic pressures can cause leaks and wear on equipment.

It is important to ensure that hydraulic pressures are maintained within safe limits.

Conclusion

Hydraulic pressure is the pressure exerted by a fluid on a stationary or movable object. It is measured in pounds per square inch (PSI). Most hydraulic systems are pressurized using either air or water. Air-pressurized systems use atmospheric pressure to force the fluid through the system. Water-pressurized systems use a controlled supply of water to push the fluid through the system.

Normal hydraulic pressure is important because it determines how much force a pump can generate, and how quickly the pump can move fluids. If normal hydraulic pressure is low, the pump will struggle to move fluids at a good rate. This can lead to inefficient operation and possible damage to equipment. Conversely, if normal hydraulic pressure is high, the pump will be able to move fluids at a faster rate, but may also create excessive force and wear on equipment. It’s important to keep normal hydraulic pressure as close as possible to its ideal value so that equipment operates smoothly and efficiently.

What is normal hydraulic pressure,please click topkitparts see more